Are you a seasoned Carbide Powder Processor seeking a new career path? Discover our professionally built Carbide Powder Processor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

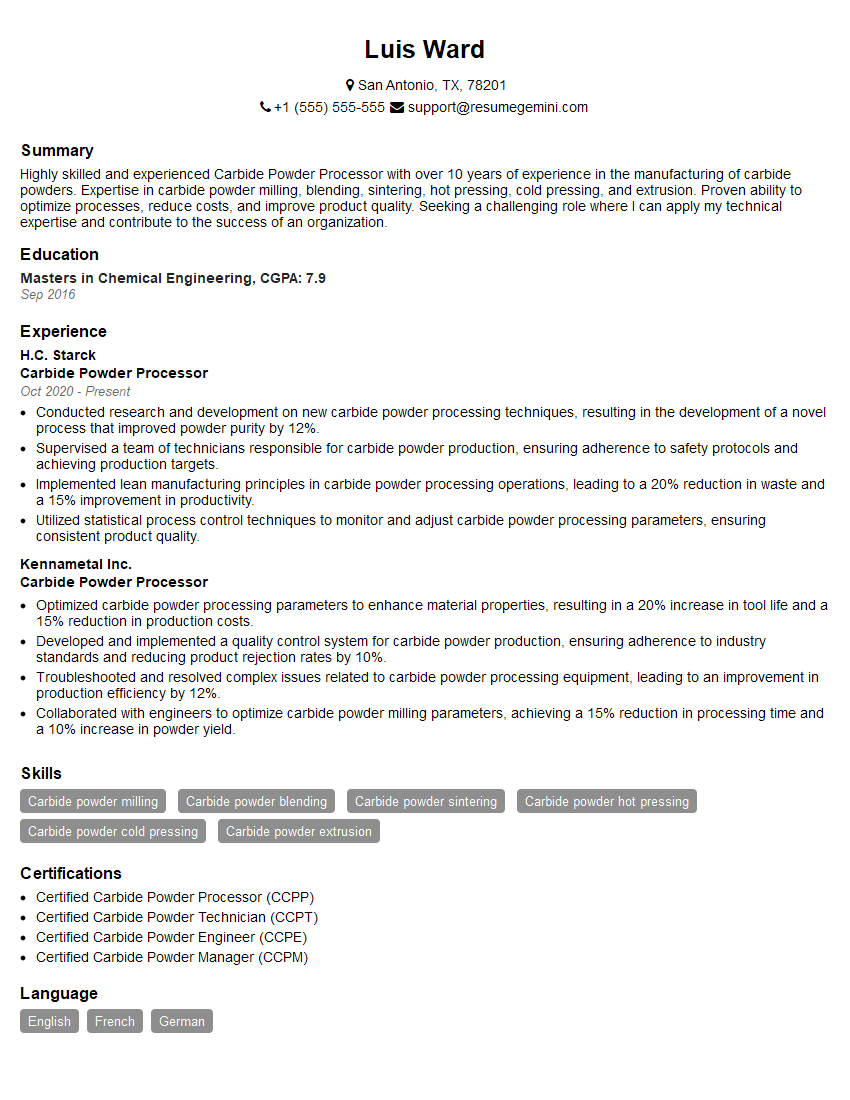

Luis Ward

Carbide Powder Processor

Summary

Highly skilled and experienced Carbide Powder Processor with over 10 years of experience in the manufacturing of carbide powders. Expertise in carbide powder milling, blending, sintering, hot pressing, cold pressing, and extrusion. Proven ability to optimize processes, reduce costs, and improve product quality. Seeking a challenging role where I can apply my technical expertise and contribute to the success of an organization.

Education

Masters in Chemical Engineering

September 2016

Skills

- Carbide powder milling

- Carbide powder blending

- Carbide powder sintering

- Carbide powder hot pressing

- Carbide powder cold pressing

- Carbide powder extrusion

Work Experience

Carbide Powder Processor

- Conducted research and development on new carbide powder processing techniques, resulting in the development of a novel process that improved powder purity by 12%.

- Supervised a team of technicians responsible for carbide powder production, ensuring adherence to safety protocols and achieving production targets.

- Implemented lean manufacturing principles in carbide powder processing operations, leading to a 20% reduction in waste and a 15% improvement in productivity.

- Utilized statistical process control techniques to monitor and adjust carbide powder processing parameters, ensuring consistent product quality.

Carbide Powder Processor

- Optimized carbide powder processing parameters to enhance material properties, resulting in a 20% increase in tool life and a 15% reduction in production costs.

- Developed and implemented a quality control system for carbide powder production, ensuring adherence to industry standards and reducing product rejection rates by 10%.

- Troubleshooted and resolved complex issues related to carbide powder processing equipment, leading to an improvement in production efficiency by 12%.

- Collaborated with engineers to optimize carbide powder milling parameters, achieving a 15% reduction in processing time and a 10% increase in powder yield.

Certificates

- Certified Carbide Powder Processor (CCPP)

- Certified Carbide Powder Technician (CCPT)

- Certified Carbide Powder Engineer (CCPE)

- Certified Carbide Powder Manager (CCPM)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Carbide Powder Processor

- Highlight your technical expertise in carbide powder processing techniques.

- Showcase your experience in optimizing processes and reducing costs.

- Emphasize your ability to work independently and as part of a team.

- Quantify your accomplishments with specific metrics and results.

- Review job descriptions carefully and tailor your resume to each specific role.

Essential Experience Highlights for a Strong Carbide Powder Processor Resume

- Operated carbide powder milling machines to grind and size carbide powder.

- Controlled and monitored carbide powder blending processes to ensure proper mixing and consistency.

- Managed carbide powder sintering furnaces to heat and bond the powder into solid form.

- Utilized hot pressing and cold pressing techniques to shape and densify carbide powders.

- Extruded carbide powder to create complex shapes and geometries.

- Conducted quality control tests to ensure compliance with specifications.

- Maintained a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Carbide Powder Processor

What is carbide powder?

Carbide powder is a fine, black powder composed of tungsten carbide particles. It is an extremely hard and wear-resistant material used in a variety of industrial applications, including cutting tools, drill bits, and wear parts.

What are the different types of carbide powder processing techniques?

The most common carbide powder processing techniques include milling, blending, sintering, hot pressing, cold pressing, and extrusion.

What is the difference between hot pressing and cold pressing?

Hot pressing involves heating the carbide powder under pressure, while cold pressing does not. Hot pressing produces a denser and stronger product than cold pressing.

What are the applications of carbide powder?

Carbide powder is used in a variety of industrial applications, including cutting tools, drill bits, wear parts, and armor.

What are the career opportunities for carbide powder processors?

Carbide powder processors can work in a variety of industries, including manufacturing, aerospace, and automotive. They can also work in research and development.

What is the salary range for carbide powder processors?

The salary range for carbide powder processors varies depending on experience, location, and industry. According to Indeed, the average salary for a carbide powder processor in the United States is $65,000 per year.