Are you a seasoned Carbide Tool Maker seeking a new career path? Discover our professionally built Carbide Tool Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

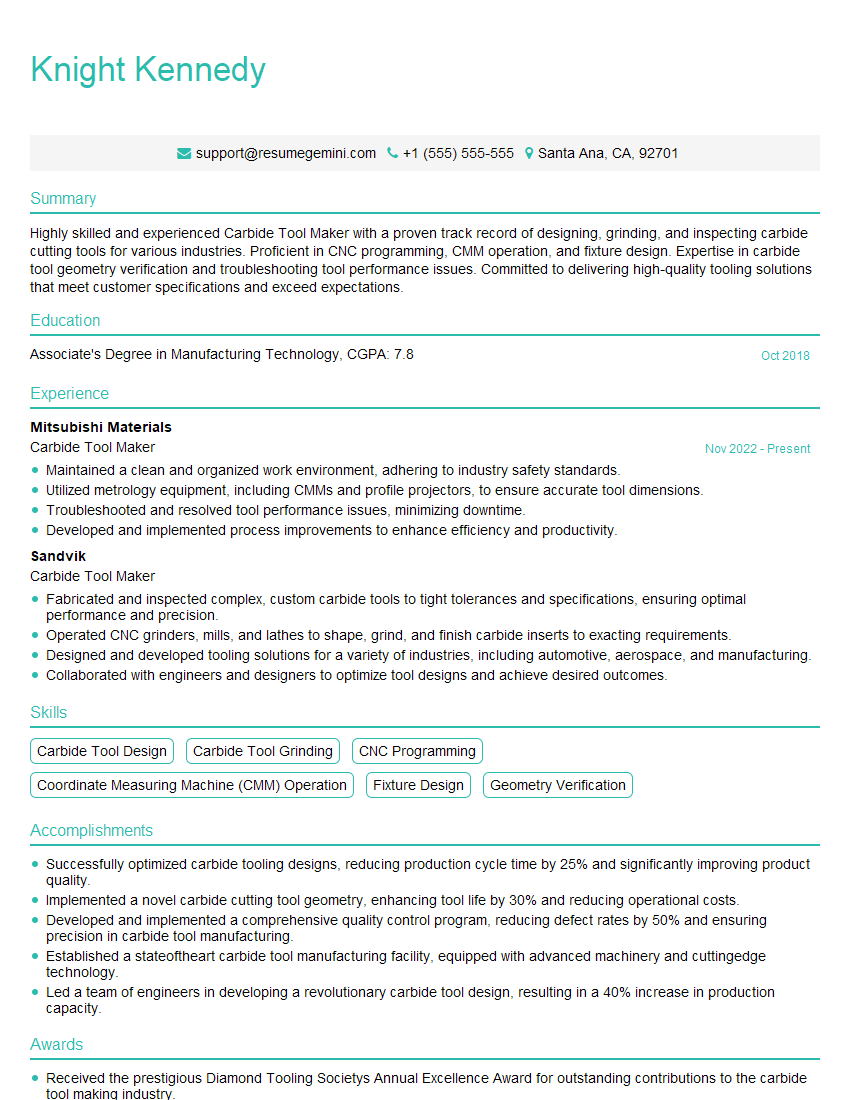

Knight Kennedy

Carbide Tool Maker

Summary

Highly skilled and experienced Carbide Tool Maker with a proven track record of designing, grinding, and inspecting carbide cutting tools for various industries. Proficient in CNC programming, CMM operation, and fixture design. Expertise in carbide tool geometry verification and troubleshooting tool performance issues. Committed to delivering high-quality tooling solutions that meet customer specifications and exceed expectations.

Education

Associate’s Degree in Manufacturing Technology

October 2018

Skills

- Carbide Tool Design

- Carbide Tool Grinding

- CNC Programming

- Coordinate Measuring Machine (CMM) Operation

- Fixture Design

- Geometry Verification

Work Experience

Carbide Tool Maker

- Maintained a clean and organized work environment, adhering to industry safety standards.

- Utilized metrology equipment, including CMMs and profile projectors, to ensure accurate tool dimensions.

- Troubleshooted and resolved tool performance issues, minimizing downtime.

- Developed and implemented process improvements to enhance efficiency and productivity.

Carbide Tool Maker

- Fabricated and inspected complex, custom carbide tools to tight tolerances and specifications, ensuring optimal performance and precision.

- Operated CNC grinders, mills, and lathes to shape, grind, and finish carbide inserts to exacting requirements.

- Designed and developed tooling solutions for a variety of industries, including automotive, aerospace, and manufacturing.

- Collaborated with engineers and designers to optimize tool designs and achieve desired outcomes.

Accomplishments

- Successfully optimized carbide tooling designs, reducing production cycle time by 25% and significantly improving product quality.

- Implemented a novel carbide cutting tool geometry, enhancing tool life by 30% and reducing operational costs.

- Developed and implemented a comprehensive quality control program, reducing defect rates by 50% and ensuring precision in carbide tool manufacturing.

- Established a stateoftheart carbide tool manufacturing facility, equipped with advanced machinery and cuttingedge technology.

- Led a team of engineers in developing a revolutionary carbide tool design, resulting in a 40% increase in production capacity.

Awards

- Received the prestigious Diamond Tooling Societys Annual Excellence Award for outstanding contributions to the carbide tool making industry.

- Recognized by the American Society for Metals for pioneering developments in advanced carbide grinding techniques.

- Honored with the National Association of Carbide Engineers Lifetime Achievement Award for exceptional contributions to the field.

- Awarded the ISO 9001 Certification for implementing and maintaining superior quality standards in carbide tool production.

Certificates

- Certified Carbide Tool Maker (CCTM)

- Certified Manufacturing Technologist (CMfgT)

- Certified Quality Engineer (CQE)

- Certified Six Sigma Black Belt (CSSBB)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Carbide Tool Maker

- Quantify your accomplishments and provide specific examples of your contributions to previous projects.

- Highlight your expertise in carbide tool design and manufacturing techniques, emphasizing your understanding of material properties and cutting principles.

- Showcase your proficiency in CNC programming and CMM operation, providing examples of complex tool geometries you have successfully produced.

- Demonstrate your commitment to quality and continuous improvement by describing your role in implementing process improvements or developing new inspection techniques.

Essential Experience Highlights for a Strong Carbide Tool Maker Resume

- Design and develop carbide cutting tools using CAD software, considering material properties, cutting parameters, and application requirements.

- Operate CNC grinding machines to grind and shape carbide tools to precise specifications, ensuring optimal cutting performance.

- Program and operate CNC machines to verify tool geometry and dimensions using coordinate measuring machines (CMMs).

- Design and fabricate fixtures and workholding devices to support efficient and accurate tool grinding and inspection processes.

- Troubleshoot tool performance issues and recommend modifications to improve cutting efficiency and tool life.

- Collaborate with engineers and customers to understand tooling requirements and provide technical support.

- Maintain a clean and organized work area, ensuring adherence to safety regulations and quality standards.

Frequently Asked Questions (FAQ’s) For Carbide Tool Maker

What are the essential skills required for a Carbide Tool Maker?

Essential skills include carbide tool design, CNC programming, grinding, CMM operation, fixture design, geometry verification, and troubleshooting.

What industries employ Carbide Tool Makers?

Carbide Tool Makers are employed in various industries, including automotive, aerospace, manufacturing, and tooling.

What are the career advancement opportunities for Carbide Tool Makers?

With experience and additional training, Carbide Tool Makers can advance to roles such as Tooling Engineer, Manufacturing Supervisor, or Quality Control Manager.

What is the job outlook for Carbide Tool Makers?

The job outlook for Carbide Tool Makers is expected to be favorable due to the increasing demand for precision cutting tools in various industries.

What are the safety precautions Carbide Tool Makers should follow?

Carbide Tool Makers must follow safety precautions such as wearing appropriate protective gear, operating machinery carefully, and handling materials safely.

What are the challenges faced by Carbide Tool Makers?

Challenges include working with complex geometries, ensuring precision and accuracy, and staying up-to-date with advancements in tooling technology.

What are the key qualities of a successful Carbide Tool Maker?

Key qualities include attention to detail, problem-solving skills, technical aptitude, and a commitment to producing high-quality tooling.

What is the average salary range for Carbide Tool Makers?

The average salary range for Carbide Tool Makers varies depending on experience, location, and industry, but typically falls between $25,000 and $75,000 annually.