Are you a seasoned Carburizing Furnace Operator seeking a new career path? Discover our professionally built Carburizing Furnace Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

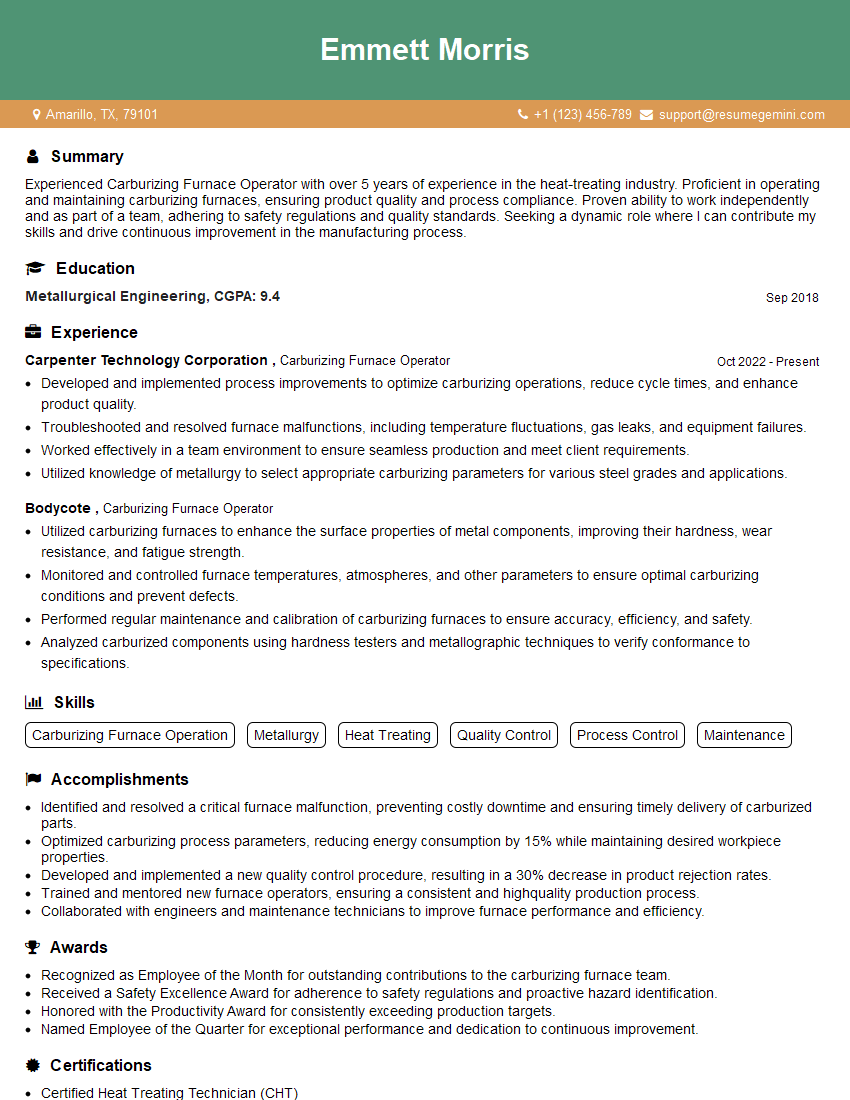

Emmett Morris

Carburizing Furnace Operator

Summary

Experienced Carburizing Furnace Operator with over 5 years of experience in the heat-treating industry. Proficient in operating and maintaining carburizing furnaces, ensuring product quality and process compliance. Proven ability to work independently and as part of a team, adhering to safety regulations and quality standards. Seeking a dynamic role where I can contribute my skills and drive continuous improvement in the manufacturing process.

Education

Metallurgical Engineering

September 2018

Skills

- Carburizing Furnace Operation

- Metallurgy

- Heat Treating

- Quality Control

- Process Control

- Maintenance

Work Experience

Carburizing Furnace Operator

- Developed and implemented process improvements to optimize carburizing operations, reduce cycle times, and enhance product quality.

- Troubleshooted and resolved furnace malfunctions, including temperature fluctuations, gas leaks, and equipment failures.

- Worked effectively in a team environment to ensure seamless production and meet client requirements.

- Utilized knowledge of metallurgy to select appropriate carburizing parameters for various steel grades and applications.

Carburizing Furnace Operator

- Utilized carburizing furnaces to enhance the surface properties of metal components, improving their hardness, wear resistance, and fatigue strength.

- Monitored and controlled furnace temperatures, atmospheres, and other parameters to ensure optimal carburizing conditions and prevent defects.

- Performed regular maintenance and calibration of carburizing furnaces to ensure accuracy, efficiency, and safety.

- Analyzed carburized components using hardness testers and metallographic techniques to verify conformance to specifications.

Accomplishments

- Identified and resolved a critical furnace malfunction, preventing costly downtime and ensuring timely delivery of carburized parts.

- Optimized carburizing process parameters, reducing energy consumption by 15% while maintaining desired workpiece properties.

- Developed and implemented a new quality control procedure, resulting in a 30% decrease in product rejection rates.

- Trained and mentored new furnace operators, ensuring a consistent and highquality production process.

- Collaborated with engineers and maintenance technicians to improve furnace performance and efficiency.

Awards

- Recognized as Employee of the Month for outstanding contributions to the carburizing furnace team.

- Received a Safety Excellence Award for adherence to safety regulations and proactive hazard identification.

- Honored with the Productivity Award for consistently exceeding production targets.

- Named Employee of the Quarter for exceptional performance and dedication to continuous improvement.

Certificates

- Certified Heat Treating Technician (CHT)

- Metallurgy Technician (MT)

- Safety Health and Environmental (SHE)

- American Society for Metals (ASM) Member

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Carburizing Furnace Operator

- Highlight your experience and expertise in carburizing furnace operation, including specific technical knowledge and skills.

- Provide quantifiable results and metrics to demonstrate your impact on productivity, quality, or cost reduction.

- Showcase your knowledge of metallurgy, heat treating processes, and quality control techniques.

- Emphasize your ability to work independently, troubleshoot problems, and maintain a safe and efficient work environment.

- Consider obtaining industry-recognized certifications, such as the Certified Heat Treater (CHT) credential, to enhance your credibility.

Essential Experience Highlights for a Strong Carburizing Furnace Operator Resume

- Operate and maintain carburizing furnaces to heat treat metal parts, ensuring proper temperatures, gas flow, and cooling cycles

- Monitor and control furnace conditions, including temperature, atmosphere composition, and pressure, to achieve desired material properties

- Inspect treated parts for defects, verify dimensions, and ensure compliance with quality specifications

- Perform routine maintenance and calibration of furnaces, including cleaning, adjustments, and repairs

- Maintain accurate records of furnace operations, including temperature charts, gas flow data, and maintenance logs

- Troubleshoot and resolve furnace malfunctions to minimize downtime and maintain production efficiency

- Follow safety protocols, wear appropriate personal protective equipment, and maintain a clean and organized work area

Frequently Asked Questions (FAQ’s) For Carburizing Furnace Operator

What is the primary responsibility of a Carburizing Furnace Operator?

The primary responsibility of a Carburizing Furnace Operator is to operate and maintain carburizing furnaces used in the heat treatment of metal parts. This involves controlling furnace conditions, monitoring treated parts, and ensuring quality and process compliance.

What skills are essential for a Carburizing Furnace Operator?

Essential skills for a Carburizing Furnace Operator include knowledge of carburizing furnace operation, metallurgy, heat treating processes, quality control, and process control. Maintenance skills are also important, as well as proficiency in troubleshooting and resolving furnace malfunctions.

What industries employ Carburizing Furnace Operators?

Carburizing Furnace Operators are employed in various industries that utilize heat treatment processes, such as automotive, aerospace, manufacturing, and metalworking.

What is the average salary for a Carburizing Furnace Operator?

The average salary for a Carburizing Furnace Operator in the United States is around $45,000 per year. However, this can vary depending on factors such as experience, location, and industry.

What are the career advancement opportunities for a Carburizing Furnace Operator?

With experience and additional training, Carburizing Furnace Operators can advance to roles such as Heat Treat Supervisor, Process Engineer, or Quality Control Manager.

What safety precautions should Carburizing Furnace Operators observe?

Carburizing Furnace Operators must adhere to strict safety protocols, including wearing appropriate personal protective equipment, following lockout/tagout procedures, and maintaining a clean and organized work area to minimize the risk of accidents.

How can I improve my skills as a Carburizing Furnace Operator?

To improve your skills as a Carburizing Furnace Operator, you can seek training opportunities, attend industry workshops and conferences, and stay up-to-date with the latest advancements in heat treating technologies and best practices.