Are you a seasoned Casing Grader seeking a new career path? Discover our professionally built Casing Grader Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

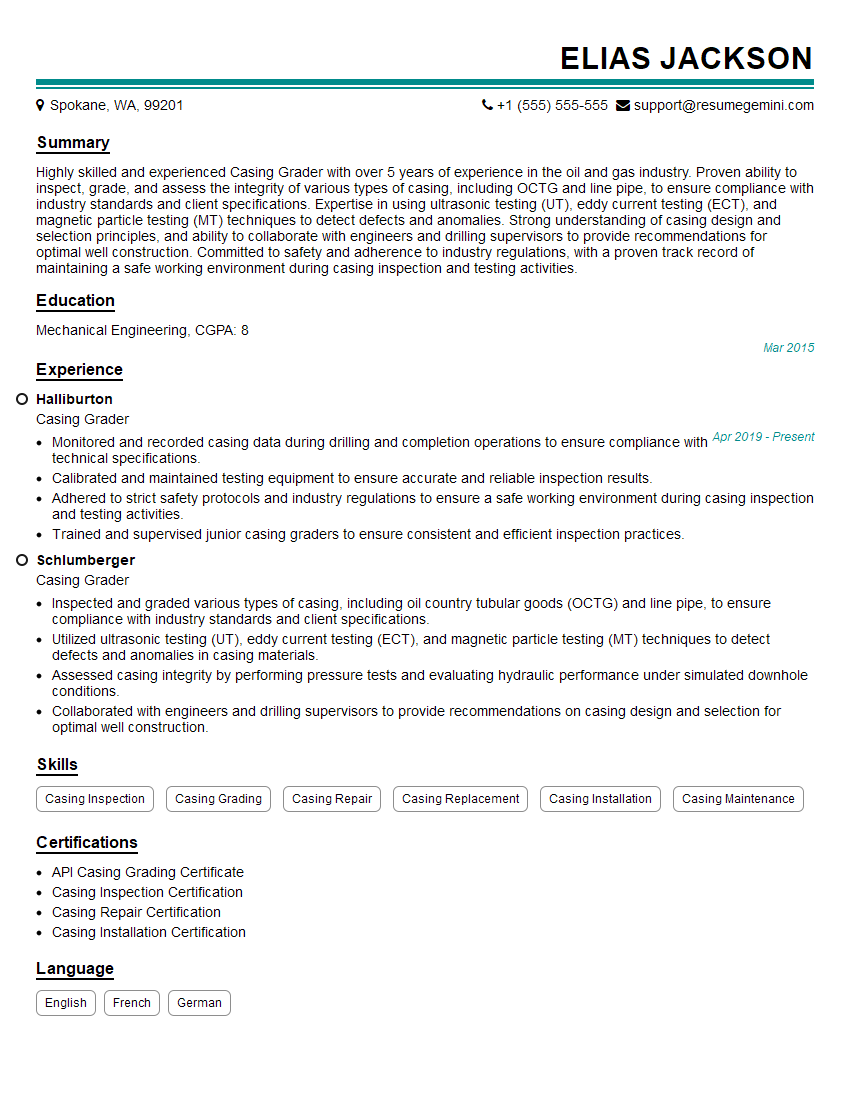

Elias Jackson

Casing Grader

Summary

Highly skilled and experienced Casing Grader with over 5 years of experience in the oil and gas industry. Proven ability to inspect, grade, and assess the integrity of various types of casing, including OCTG and line pipe, to ensure compliance with industry standards and client specifications. Expertise in using ultrasonic testing (UT), eddy current testing (ECT), and magnetic particle testing (MT) techniques to detect defects and anomalies. Strong understanding of casing design and selection principles, and ability to collaborate with engineers and drilling supervisors to provide recommendations for optimal well construction. Committed to safety and adherence to industry regulations, with a proven track record of maintaining a safe working environment during casing inspection and testing activities.

Education

Mechanical Engineering

March 2015

Skills

- Casing Inspection

- Casing Grading

- Casing Repair

- Casing Replacement

- Casing Installation

- Casing Maintenance

Work Experience

Casing Grader

- Monitored and recorded casing data during drilling and completion operations to ensure compliance with technical specifications.

- Calibrated and maintained testing equipment to ensure accurate and reliable inspection results.

- Adhered to strict safety protocols and industry regulations to ensure a safe working environment during casing inspection and testing activities.

- Trained and supervised junior casing graders to ensure consistent and efficient inspection practices.

Casing Grader

- Inspected and graded various types of casing, including oil country tubular goods (OCTG) and line pipe, to ensure compliance with industry standards and client specifications.

- Utilized ultrasonic testing (UT), eddy current testing (ECT), and magnetic particle testing (MT) techniques to detect defects and anomalies in casing materials.

- Assessed casing integrity by performing pressure tests and evaluating hydraulic performance under simulated downhole conditions.

- Collaborated with engineers and drilling supervisors to provide recommendations on casing design and selection for optimal well construction.

Certificates

- API Casing Grading Certificate

- Casing Inspection Certification

- Casing Repair Certification

- Casing Installation Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Casing Grader

- Highlight your technical skills and experience in casing inspection and testing.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Demonstrate your understanding of casing design and selection principles, and your ability to collaborate with engineers.

- Emphasize your commitment to safety and your experience in maintaining a safe working environment.

Essential Experience Highlights for a Strong Casing Grader Resume

- Inspected and graded various types of casing, including OCTG and line pipe, to ensure compliance with industry standards and client specifications.

- Utilized ultrasonic testing (UT), eddy current testing (ECT), and magnetic particle testing (MT) techniques to detect defects and anomalies in casing materials.

- Assessed casing integrity by performing pressure tests and evaluating hydraulic performance under simulated downhole conditions.

- Collaborated with engineers and drilling supervisors to provide recommendations on casing design and selection for optimal well construction.

- Monitored and recorded casing data during drilling and completion operations to ensure compliance with technical specifications.

- Calibrated and maintained testing equipment to ensure accurate and reliable inspection results.

- Adhered to strict safety protocols and industry regulations to ensure a safe working environment during casing inspection and testing activities.

Frequently Asked Questions (FAQ’s) For Casing Grader

What is the role of a Casing Grader?

A Casing Grader is responsible for inspecting, grading, and assessing the integrity of casing materials, including oil country tubular goods (OCTG) and line pipe, to ensure compliance with industry standards and client specifications.

What are the key skills required for a Casing Grader?

Key skills for a Casing Grader include proficiency in casing inspection and testing techniques, such as UT, ECT, and MT; understanding of casing design and selection principles; ability to collaborate with engineers and drilling supervisors; and commitment to safety.

What are the career prospects for a Casing Grader?

Casing Graders can advance to roles such as Casing Supervisor, Quality Control Inspector, or Technical Advisor.

What is the typical salary range for a Casing Grader?

The salary range for a Casing Grader can vary depending on experience, location, and company size, but typically falls between $60,000 and $120,000 per year.

What are the educational requirements for a Casing Grader?

Casing Graders typically hold a degree in Mechanical Engineering or a related field.

What are the key challenges faced by a Casing Grader?

Key challenges for a Casing Grader include working in demanding environments, exposure to hazardous materials, and the need to stay updated with industry standards and regulations.

What are the key trends in the Casing Grader industry?

The Casing Grader industry is evolving with the development of new inspection technologies and the increasing use of automation and data analytics.