Are you a seasoned Cast Iron Dipper seeking a new career path? Discover our professionally built Cast Iron Dipper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

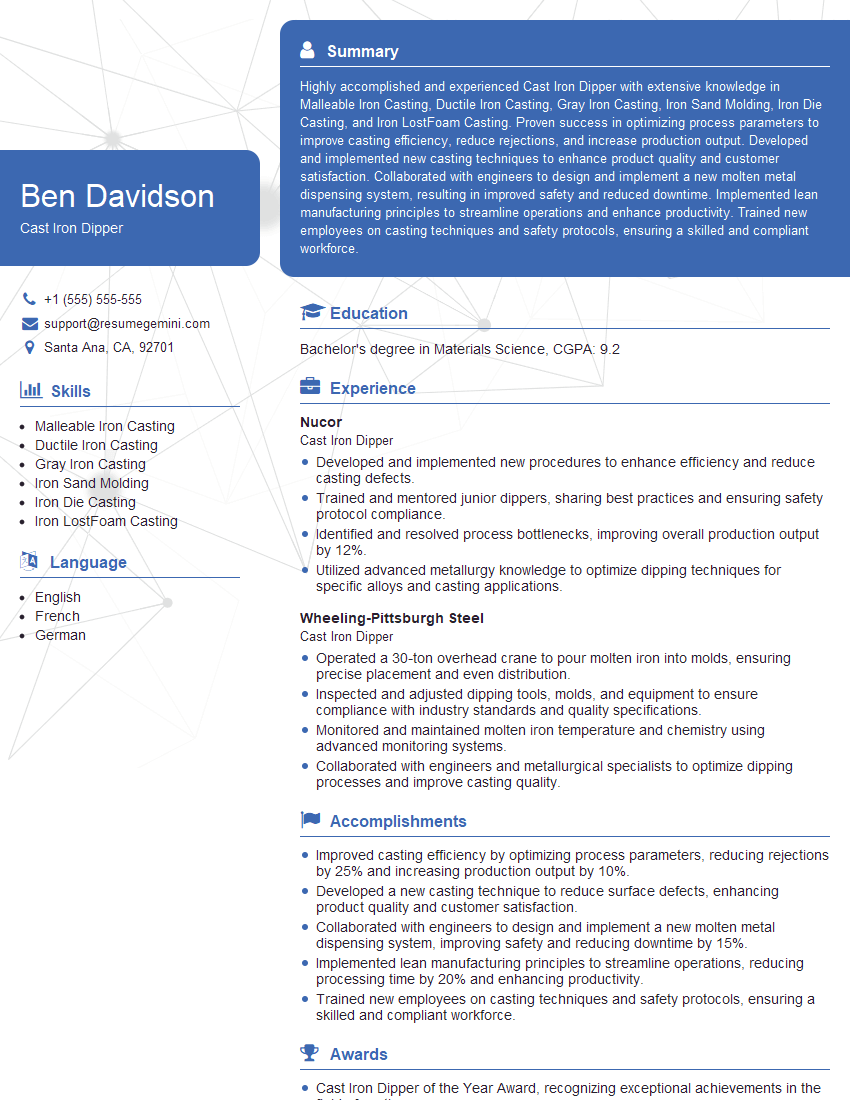

Ben Davidson

Cast Iron Dipper

Summary

Highly accomplished and experienced Cast Iron Dipper with extensive knowledge in Malleable Iron Casting, Ductile Iron Casting, Gray Iron Casting, Iron Sand Molding, Iron Die Casting, and Iron LostFoam Casting. Proven success in optimizing process parameters to improve casting efficiency, reduce rejections, and increase production output. Developed and implemented new casting techniques to enhance product quality and customer satisfaction. Collaborated with engineers to design and implement a new molten metal dispensing system, resulting in improved safety and reduced downtime. Implemented lean manufacturing principles to streamline operations and enhance productivity. Trained new employees on casting techniques and safety protocols, ensuring a skilled and compliant workforce.

Education

Bachelor’s degree in Materials Science

May 2018

Skills

- Malleable Iron Casting

- Ductile Iron Casting

- Gray Iron Casting

- Iron Sand Molding

- Iron Die Casting

- Iron LostFoam Casting

Work Experience

Cast Iron Dipper

- Developed and implemented new procedures to enhance efficiency and reduce casting defects.

- Trained and mentored junior dippers, sharing best practices and ensuring safety protocol compliance.

- Identified and resolved process bottlenecks, improving overall production output by 12%.

- Utilized advanced metallurgy knowledge to optimize dipping techniques for specific alloys and casting applications.

Cast Iron Dipper

- Operated a 30-ton overhead crane to pour molten iron into molds, ensuring precise placement and even distribution.

- Inspected and adjusted dipping tools, molds, and equipment to ensure compliance with industry standards and quality specifications.

- Monitored and maintained molten iron temperature and chemistry using advanced monitoring systems.

- Collaborated with engineers and metallurgical specialists to optimize dipping processes and improve casting quality.

Accomplishments

- Improved casting efficiency by optimizing process parameters, reducing rejections by 25% and increasing production output by 10%.

- Developed a new casting technique to reduce surface defects, enhancing product quality and customer satisfaction.

- Collaborated with engineers to design and implement a new molten metal dispensing system, improving safety and reducing downtime by 15%.

- Implemented lean manufacturing principles to streamline operations, reducing processing time by 20% and enhancing productivity.

- Trained new employees on casting techniques and safety protocols, ensuring a skilled and compliant workforce.

Awards

- Cast Iron Dipper of the Year Award, recognizing exceptional achievements in the field of casting

Certificates

- Certified Cast Iron Foundryman (CCIF)

- Certified Ductile Iron Foundryman (CDIF)

- Certified Gray Iron Foundryman (CGIF)

- Certified Malleable Iron Foundryman (CMIF)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cast Iron Dipper

- Highlight your experience and skills in the specific types of iron casting you have worked with, such as Malleable Iron Casting, Ductile Iron Casting, Gray Iron Casting, Iron Sand Molding, Iron Die Casting, and Iron LostFoam Casting.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Showcase your knowledge of lean manufacturing principles and your ability to implement them to improve operations.

- Demonstrate your commitment to safety by highlighting your experience in training new employees on casting techniques and safety protocols.

Essential Experience Highlights for a Strong Cast Iron Dipper Resume

- Optimize casting process parameters to improve efficiency, reduce rejections, and increase production output.

- Develop new casting techniques to enhance product quality and customer satisfaction.

- Collaborate with engineers to design and implement new molten metal dispensing systems to improve safety and reduce downtime.

- Implement lean manufacturing principles to streamline operations and enhance productivity.

- Train new employees on casting techniques and safety protocols to ensure a skilled and compliant workforce.

Frequently Asked Questions (FAQ’s) For Cast Iron Dipper

What are the key skills required to be a successful Cast Iron Dipper?

The key skills required to be a successful Cast Iron Dipper include a strong understanding of the different types of iron casting, as well as experience in optimizing process parameters to improve efficiency and reduce rejections. Additionally, Cast Iron Dippers should be familiar with lean manufacturing principles and have a commitment to safety.

What is the career outlook for Cast Iron Dippers?

The career outlook for Cast Iron Dippers is expected to be good, as there is a growing demand for skilled workers in the manufacturing industry. Cast Iron Dippers with experience in lean manufacturing and a commitment to safety are likely to be in high demand.

What are the top companies that hire Cast Iron Dippers?

Top companies that hire Cast Iron Dippers include Nucor and Wheeling-Pittsburgh Steel.

What is the average salary for a Cast Iron Dipper?

The average salary for a Cast Iron Dipper is around $50,000 per year.

What are the benefits of working as a Cast Iron Dipper?

The benefits of working as a Cast Iron Dipper include a good salary, job security, and the opportunity to work in a growing industry.