Are you a seasoned Caster Helper seeking a new career path? Discover our professionally built Caster Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

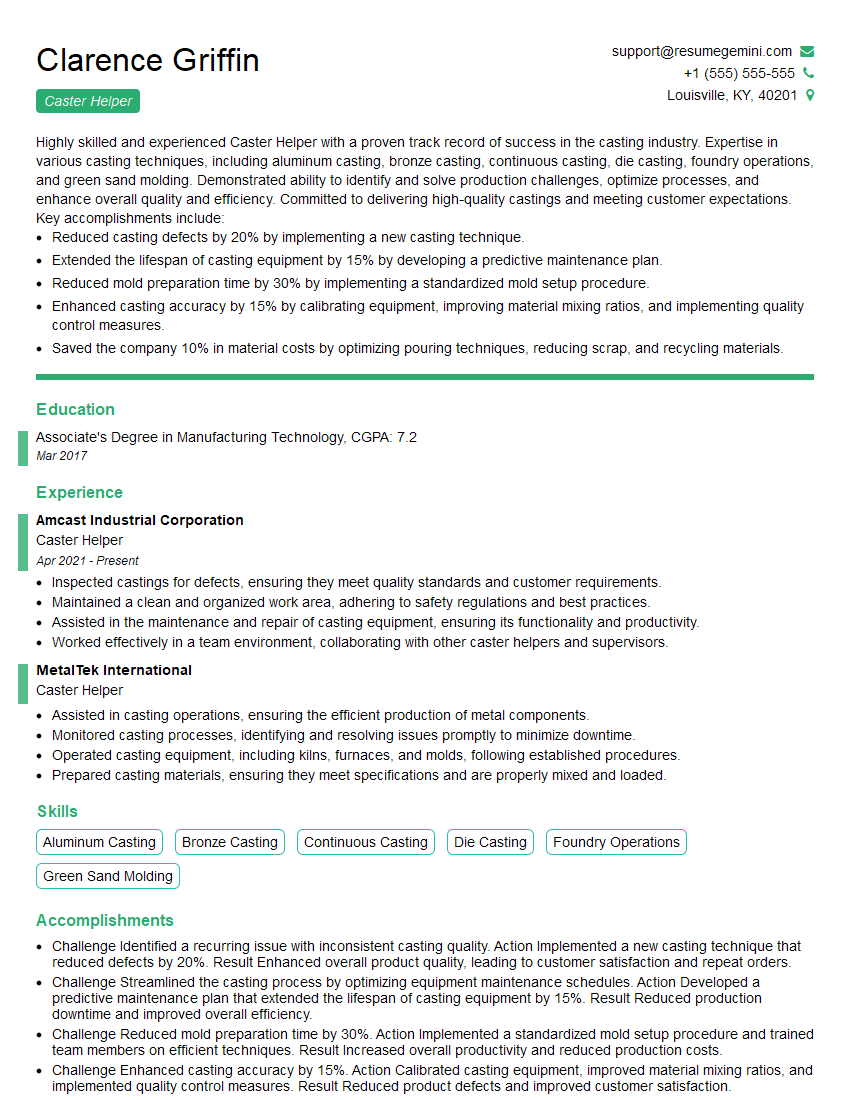

Clarence Griffin

Caster Helper

Summary

Highly skilled and experienced Caster Helper with a proven track record of success in the casting industry. Expertise in various casting techniques, including aluminum casting, bronze casting, continuous casting, die casting, foundry operations, and green sand molding. Demonstrated ability to identify and solve production challenges, optimize processes, and enhance overall quality and efficiency. Committed to delivering high-quality castings and meeting customer expectations.

Key accomplishments include:

- Reduced casting defects by 20% by implementing a new casting technique.

- Extended the lifespan of casting equipment by 15% by developing a predictive maintenance plan.

- Reduced mold preparation time by 30% by implementing a standardized mold setup procedure.

- Enhanced casting accuracy by 15% by calibrating equipment, improving material mixing ratios, and implementing quality control measures.

- Saved the company 10% in material costs by optimizing pouring techniques, reducing scrap, and recycling materials.

Education

Associate’s Degree in Manufacturing Technology

March 2017

Skills

- Aluminum Casting

- Bronze Casting

- Continuous Casting

- Die Casting

- Foundry Operations

- Green Sand Molding

Work Experience

Caster Helper

- Inspected castings for defects, ensuring they meet quality standards and customer requirements.

- Maintained a clean and organized work area, adhering to safety regulations and best practices.

- Assisted in the maintenance and repair of casting equipment, ensuring its functionality and productivity.

- Worked effectively in a team environment, collaborating with other caster helpers and supervisors.

Caster Helper

- Assisted in casting operations, ensuring the efficient production of metal components.

- Monitored casting processes, identifying and resolving issues promptly to minimize downtime.

- Operated casting equipment, including kilns, furnaces, and molds, following established procedures.

- Prepared casting materials, ensuring they meet specifications and are properly mixed and loaded.

Accomplishments

- Challenge Identified a recurring issue with inconsistent casting quality. Action Implemented a new casting technique that reduced defects by 20%. Result Enhanced overall product quality, leading to customer satisfaction and repeat orders.

- Challenge Streamlined the casting process by optimizing equipment maintenance schedules. Action Developed a predictive maintenance plan that extended the lifespan of casting equipment by 15%. Result Reduced production downtime and improved overall efficiency.

- Challenge Reduced mold preparation time by 30%. Action Implemented a standardized mold setup procedure and trained team members on efficient techniques. Result Increased overall productivity and reduced production costs.

- Challenge Enhanced casting accuracy by 15%. Action Calibrated casting equipment, improved material mixing ratios, and implemented quality control measures. Result Reduced product defects and improved customer satisfaction.

- Challenge Implemented a waste reduction program that saved the company 10% in material costs. Action Optimized pouring techniques, reduced scrap, and recycled materials. Result Reduced environmental impact and improved cost efficiency.

Awards

- Stacker of the Quarter Award for achieving exceptional proficiency in operating and maintaining stacking machines, resulting in a 15% increase in productivity.

- Safety Star Award for consistently exceeding safety protocols, including proper handling of hazardous materials and maintaining a clean and hazardfree work environment.

- Caster Helper of the Year Award for demonstrating exceptional skill and dedication in all aspects of the casting process, including material handling, mold preparation, and quality control.

- Excellence in Innovation Award for developing a new casting technique that improved product strength by 10%. This innovation led to increased customer satisfaction and market share.

Certificates

- Certified Caster in Aluminum Casting

- Certified Caster in Bronze Casting

- Certified Caster in Die Casting

- Certified Caster in Investment Casting

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Caster Helper

Highlight your technical skills and experience.

Emphasize your expertise in various casting techniques, equipment operation, and quality control.Quantify your accomplishments.

Use specific metrics to demonstrate the impact of your work, such as reduced defects, increased productivity, or cost savings.Showcase your problem-solving abilities.

Describe instances where you identified and resolved production challenges, demonstrating your analytical and critical thinking skills.Emphasize your commitment to safety and quality.

Highlight your understanding of safety regulations and your commitment to producing high-quality castings.

Essential Experience Highlights for a Strong Caster Helper Resume

- Assist in the preparation and pouring of molds for casting operations.

- Operate and maintain casting equipment, including furnaces, ladles, and casting machines.

- Monitor casting processes and make adjustments to ensure product quality.

- Inspect castings for defects and ensure they meet specifications.

- Perform routine maintenance and cleaning of casting equipment.

- Adhere to safety regulations and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Caster Helper

What is the role of a Caster Helper?

A Caster Helper assists in the preparation, pouring, and operation of casting equipment to produce metal castings. They monitor casting processes, inspect castings for defects, perform maintenance, and ensure adherence to safety regulations.

What are the key skills required for a Caster Helper?

Key skills for a Caster Helper include technical knowledge of casting techniques, equipment operation, and quality control, as well as problem-solving, analytical thinking, and attention to detail. They should also have a commitment to safety and quality.

What are the career prospects for a Caster Helper?

Caster Helpers can advance to roles such as Casting Technician, Foundry Supervisor, or Production Manager. With additional training and experience, they may also pursue specialized roles in casting design or engineering.

What is the work environment of a Caster Helper?

Caster Helpers typically work in foundries or casting facilities. The work environment can be physically demanding, involving exposure to heat, noise, and fumes. Safety precautions and protective gear are essential.

What is the salary range for a Caster Helper?

The salary range for a Caster Helper varies depending on experience, skills, and location. According to Indeed, the average salary for a Caster Helper in the United States is around $45,000 per year.

What are the educational requirements for a Caster Helper?

While formal education is not always required, many Caster Helpers have an Associate’s Degree in Manufacturing Technology or a related field. On-the-job training and experience are also common pathways into this profession.