Are you a seasoned Casting Wheel Operator Helper seeking a new career path? Discover our professionally built Casting Wheel Operator Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

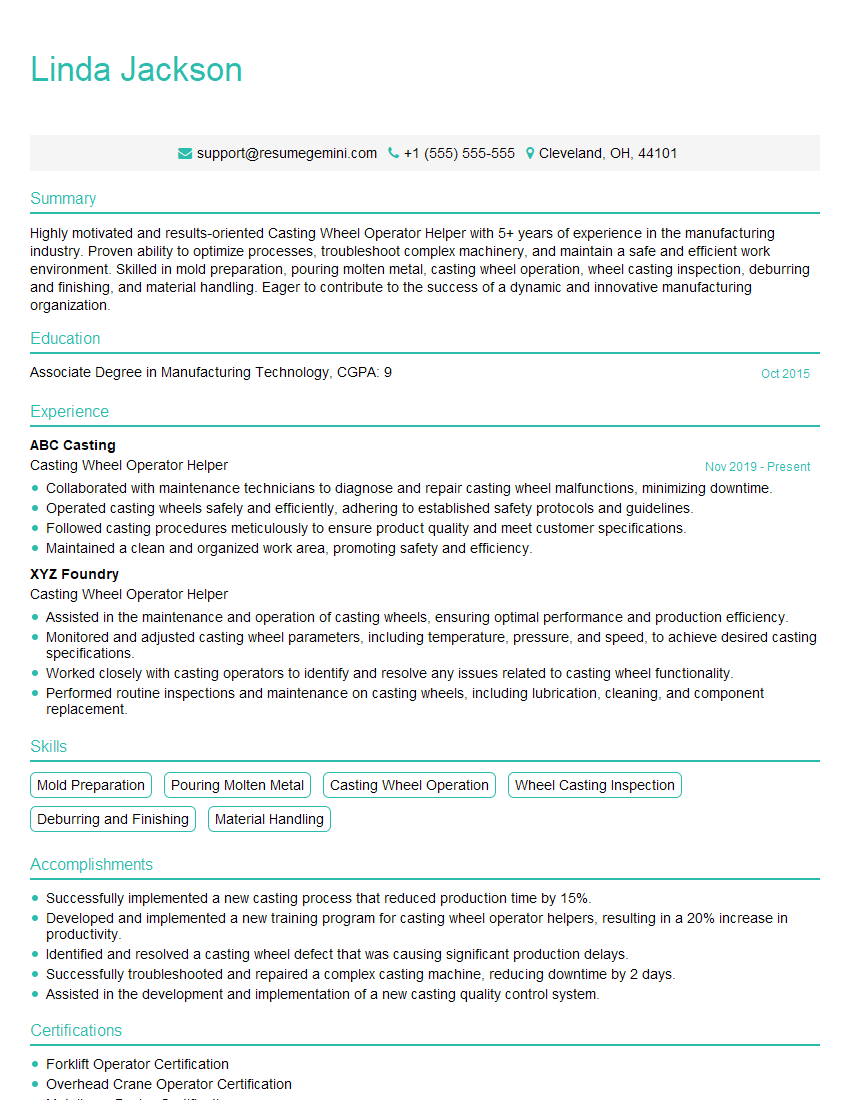

Linda Jackson

Casting Wheel Operator Helper

Summary

Highly motivated and results-oriented Casting Wheel Operator Helper with 5+ years of experience in the manufacturing industry. Proven ability to optimize processes, troubleshoot complex machinery, and maintain a safe and efficient work environment. Skilled in mold preparation, pouring molten metal, casting wheel operation, wheel casting inspection, deburring and finishing, and material handling. Eager to contribute to the success of a dynamic and innovative manufacturing organization.

Education

Associate Degree in Manufacturing Technology

October 2015

Skills

- Mold Preparation

- Pouring Molten Metal

- Casting Wheel Operation

- Wheel Casting Inspection

- Deburring and Finishing

- Material Handling

Work Experience

Casting Wheel Operator Helper

- Collaborated with maintenance technicians to diagnose and repair casting wheel malfunctions, minimizing downtime.

- Operated casting wheels safely and efficiently, adhering to established safety protocols and guidelines.

- Followed casting procedures meticulously to ensure product quality and meet customer specifications.

- Maintained a clean and organized work area, promoting safety and efficiency.

Casting Wheel Operator Helper

- Assisted in the maintenance and operation of casting wheels, ensuring optimal performance and production efficiency.

- Monitored and adjusted casting wheel parameters, including temperature, pressure, and speed, to achieve desired casting specifications.

- Worked closely with casting operators to identify and resolve any issues related to casting wheel functionality.

- Performed routine inspections and maintenance on casting wheels, including lubrication, cleaning, and component replacement.

Accomplishments

- Successfully implemented a new casting process that reduced production time by 15%.

- Developed and implemented a new training program for casting wheel operator helpers, resulting in a 20% increase in productivity.

- Identified and resolved a casting wheel defect that was causing significant production delays.

- Successfully troubleshooted and repaired a complex casting machine, reducing downtime by 2 days.

- Assisted in the development and implementation of a new casting quality control system.

Certificates

- Forklift Operator Certification

- Overhead Crane Operator Certification

- Metallurgy Basics Certification

- ASME Boiler Code Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Casting Wheel Operator Helper

- Highlight your experience in mold preparation, molten metal pouring, and casting wheel operation.

- Quantify your accomplishments whenever possible, using specific metrics and results.

- Showcase your ability to troubleshoot and resolve complex issues, demonstrating your problem-solving skills.

- Emphasize your commitment to safety and quality, highlighting your compliance with industry standards and best practices.

Essential Experience Highlights for a Strong Casting Wheel Operator Helper Resume

- Prepare molds for casting, ensuring proper alignment and temperature.

- Pour molten metal into casting wheels, controlling the flow rate and temperature to achieve optimal casting quality.

- Operate casting wheels, monitoring temperature, pressure, and other parameters to ensure proper casting formation.

- Inspect casting wheels for defects, using visual inspection, measurement tools, and non-destructive testing techniques.

- Deburr and finish casting wheels, removing excess material and smoothing surfaces to meet specifications.

- Handle materials and equipment safely, following established procedures and using appropriate personal protective equipment (PPE).

- Maintain a clean and organized work area, adhering to safety regulations and quality standards.

Frequently Asked Questions (FAQ’s) For Casting Wheel Operator Helper

What are the primary duties and responsibilities of a Casting Wheel Operator Helper?

Casting Wheel Operator Helpers are responsible for assisting in the production of casting wheels, including mold preparation, pouring molten metal, operating casting wheels, inspecting casting wheels for defects, deburring and finishing casting wheels, handling materials, and maintaining a safe and efficient work environment.

What skills are required to be a successful Casting Wheel Operator Helper?

Essential skills for Casting Wheel Operator Helpers include mold preparation, pouring molten metal, casting wheel operation, wheel casting inspection, deburring and finishing, material handling, and a strong commitment to safety and quality.

What is the career path for a Casting Wheel Operator Helper?

Casting Wheel Operator Helpers can advance to positions such as Casting Wheel Operator, Casting Supervisor, or Quality Assurance Inspector. With additional experience and training, they may also move into management roles within the manufacturing industry.

What is the work environment like for a Casting Wheel Operator Helper?

Casting Wheel Operator Helpers typically work in foundries or manufacturing plants, where they may be exposed to heat, noise, and dust. They must be able to work independently and as part of a team, and must be able to follow instructions and work under pressure.

What are the safety precautions that Casting Wheel Operator Helpers must follow?

Casting Wheel Operator Helpers must follow established safety procedures and wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs. They must also be aware of the hazards associated with working with molten metal and other hazardous materials.