Are you a seasoned Cellophane Tester seeking a new career path? Discover our professionally built Cellophane Tester Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

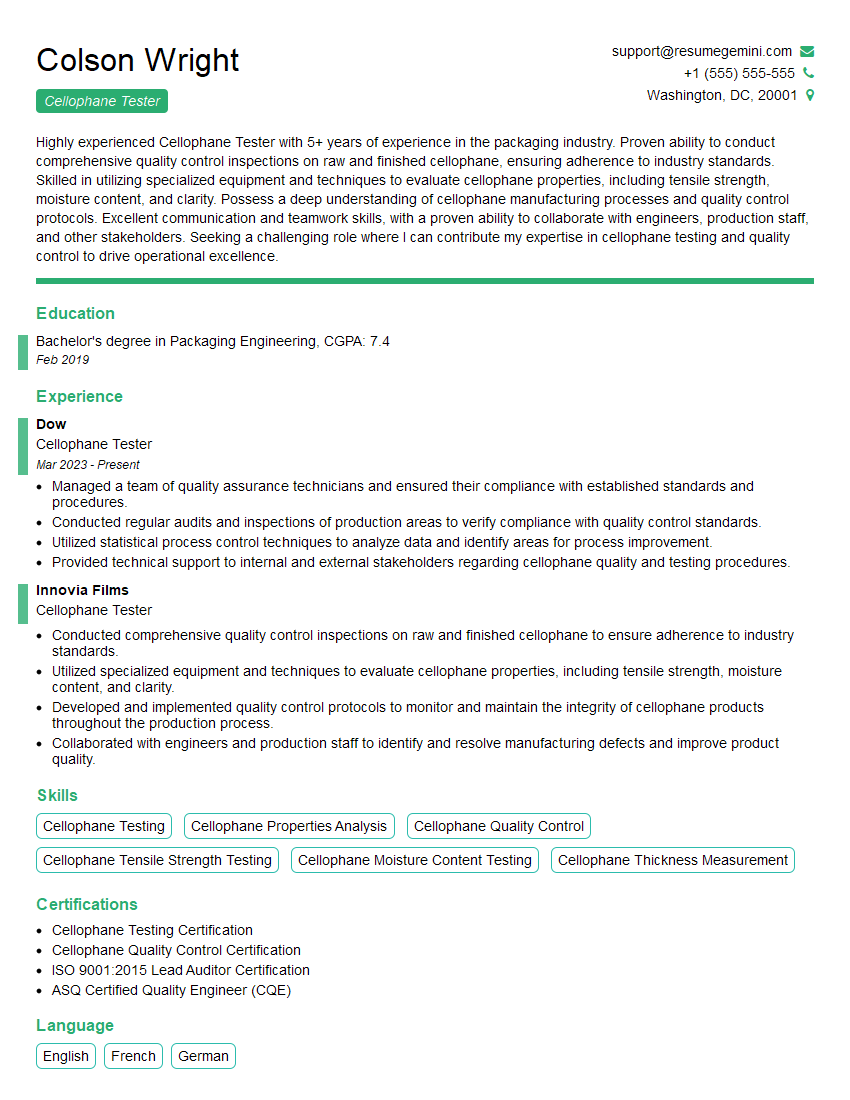

Colson Wright

Cellophane Tester

Summary

Highly experienced Cellophane Tester with 5+ years of experience in the packaging industry. Proven ability to conduct comprehensive quality control inspections on raw and finished cellophane, ensuring adherence to industry standards. Skilled in utilizing specialized equipment and techniques to evaluate cellophane properties, including tensile strength, moisture content, and clarity. Possess a deep understanding of cellophane manufacturing processes and quality control protocols. Excellent communication and teamwork skills, with a proven ability to collaborate with engineers, production staff, and other stakeholders. Seeking a challenging role where I can contribute my expertise in cellophane testing and quality control to drive operational excellence.

Education

Bachelor’s degree in Packaging Engineering

February 2019

Skills

- Cellophane Testing

- Cellophane Properties Analysis

- Cellophane Quality Control

- Cellophane Tensile Strength Testing

- Cellophane Moisture Content Testing

- Cellophane Thickness Measurement

Work Experience

Cellophane Tester

- Managed a team of quality assurance technicians and ensured their compliance with established standards and procedures.

- Conducted regular audits and inspections of production areas to verify compliance with quality control standards.

- Utilized statistical process control techniques to analyze data and identify areas for process improvement.

- Provided technical support to internal and external stakeholders regarding cellophane quality and testing procedures.

Cellophane Tester

- Conducted comprehensive quality control inspections on raw and finished cellophane to ensure adherence to industry standards.

- Utilized specialized equipment and techniques to evaluate cellophane properties, including tensile strength, moisture content, and clarity.

- Developed and implemented quality control protocols to monitor and maintain the integrity of cellophane products throughout the production process.

- Collaborated with engineers and production staff to identify and resolve manufacturing defects and improve product quality.

Certificates

- Cellophane Testing Certification

- Cellophane Quality Control Certification

- ISO 9001:2015 Lead Auditor Certification

- ASQ Certified Quality Engineer (CQE)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cellophane Tester

- Highlight your technical skills and experience in cellophane testing, including the specific equipment and techniques you are proficient in.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work on product quality and process improvement.

- Showcase your ability to collaborate effectively with cross-functional teams, including engineers, production staff, and quality assurance technicians.

- Stay up-to-date on the latest industry standards and best practices in cellophane testing and quality control.

- Consider obtaining certifications, such as the Certified Packaging Professional (CPP) certification, to enhance your credibility and demonstrate your commitment to the profession.

Essential Experience Highlights for a Strong Cellophane Tester Resume

- Conducted comprehensive quality control inspections on raw and finished cellophane to ensure adherence to industry standards.

- Utilized specialized equipment and techniques to evaluate cellophane properties, including tensile strength, moisture content, and clarity.

- Developed and implemented quality control protocols to monitor and maintain the integrity of cellophane products throughout the production process.

- Collaborated with engineers and production staff to identify and resolve manufacturing defects and improve product quality.

- Managed a team of quality assurance technicians and ensured their compliance with established standards and procedures.

- Conducted regular audits and inspections of production areas to verify compliance with quality control standards.

Frequently Asked Questions (FAQ’s) For Cellophane Tester

What are the key qualities of a successful Cellophane Tester?

A successful Cellophane Tester should possess a strong understanding of cellophane properties and testing procedures, as well as excellent analytical and problem-solving skills. They should be meticulous and detail-oriented, with a keen eye for identifying defects and non-conformities. Additionally, effective communication and teamwork skills are essential for collaborating with cross-functional teams and ensuring that quality standards are met.

What are the growth opportunities for a Cellophane Tester?

Cellophane Testers can advance their careers by taking on leadership roles within their organizations, such as Quality Control Supervisor or Manager. They can also specialize in specific areas of cellophane testing, such as tensile strength testing or moisture content analysis. With experience and expertise, Cellophane Testers can also become involved in research and development, contributing to the advancement of cellophane manufacturing and testing practices.

What are the key challenges faced by Cellophane Testers?

Cellophane Testers face several challenges in their work, including ensuring the accuracy and reliability of test results, staying up-to-date with evolving industry standards, and identifying and solving manufacturing defects. Additionally, Cellophane Testers must be able to work effectively in a fast-paced and demanding production environment, ensuring that products meet quality standards while maintaining efficiency.

What are the latest trends and advancements in Cellophane Testing?

The field of Cellophane Testing is constantly evolving, with new technologies and techniques being developed to improve the accuracy, efficiency, and speed of testing. Some of the latest trends include the use of automated testing equipment, non-destructive testing methods, and advanced data analysis techniques. Additionally, there is a growing focus on sustainability in the packaging industry, leading to the development of eco-friendly cellophane testing methods.