Are you a seasoned Cement Fittings Maker seeking a new career path? Discover our professionally built Cement Fittings Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

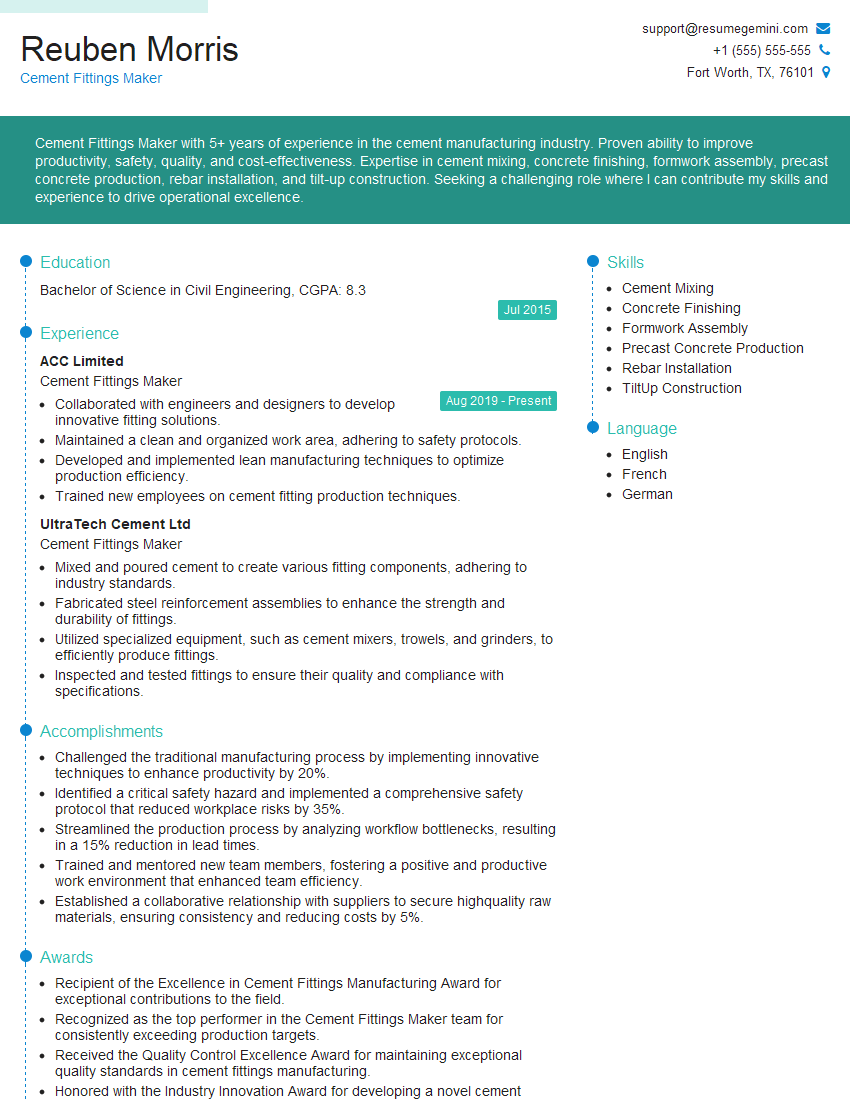

Reuben Morris

Cement Fittings Maker

Summary

Cement Fittings Maker with 5+ years of experience in the cement manufacturing industry. Proven ability to improve productivity, safety, quality, and cost-effectiveness. Expertise in cement mixing, concrete finishing, formwork assembly, precast concrete production, rebar installation, and tilt-up construction. Seeking a challenging role where I can contribute my skills and experience to drive operational excellence.

Education

Bachelor of Science in Civil Engineering

July 2015

Skills

- Cement Mixing

- Concrete Finishing

- Formwork Assembly

- Precast Concrete Production

- Rebar Installation

- TiltUp Construction

Work Experience

Cement Fittings Maker

- Collaborated with engineers and designers to develop innovative fitting solutions.

- Maintained a clean and organized work area, adhering to safety protocols.

- Developed and implemented lean manufacturing techniques to optimize production efficiency.

- Trained new employees on cement fitting production techniques.

Cement Fittings Maker

- Mixed and poured cement to create various fitting components, adhering to industry standards.

- Fabricated steel reinforcement assemblies to enhance the strength and durability of fittings.

- Utilized specialized equipment, such as cement mixers, trowels, and grinders, to efficiently produce fittings.

- Inspected and tested fittings to ensure their quality and compliance with specifications.

Accomplishments

- Challenged the traditional manufacturing process by implementing innovative techniques to enhance productivity by 20%.

- Identified a critical safety hazard and implemented a comprehensive safety protocol that reduced workplace risks by 35%.

- Streamlined the production process by analyzing workflow bottlenecks, resulting in a 15% reduction in lead times.

- Trained and mentored new team members, fostering a positive and productive work environment that enhanced team efficiency.

- Established a collaborative relationship with suppliers to secure highquality raw materials, ensuring consistency and reducing costs by 5%.

Awards

- Recipient of the Excellence in Cement Fittings Manufacturing Award for exceptional contributions to the field.

- Recognized as the top performer in the Cement Fittings Maker team for consistently exceeding production targets.

- Received the Quality Control Excellence Award for maintaining exceptional quality standards in cement fittings manufacturing.

- Honored with the Industry Innovation Award for developing a novel cement fitting design that improved product performance by 10%.

Certificates

- American Concrete Institute (ACI) Certification

- National Ready Mixed Concrete Association (NRMCA) Certification

- OSHA 10Hour Construction Safety Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cement Fittings Maker

- Highlight your experience and skills in the cement manufacturing industry.

- Quantify your accomplishments with specific metrics.

- Showcase your knowledge of safety protocols and regulations.

- Demonstrate your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Cement Fittings Maker Resume

- Mix cement and other materials to create concrete.

- Pour concrete into molds and forms.

- Finish and smooth concrete surfaces.

- Assemble and install formwork.

- Install rebar and other reinforcements.

- Operate tilt-up machines to lift and place precast concrete panels.

Frequently Asked Questions (FAQ’s) For Cement Fittings Maker

What is the role of a Cement Fittings Maker?

A Cement Fittings Maker is responsible for the production of cement fittings, including pipes, fittings, and other components used in the construction industry.

What are the key skills required to be a successful Cement Fittings Maker?

Key skills include knowledge of cement mixing, concrete finishing, formwork assembly, precast concrete production, rebar installation, and tilt-up construction.

What is the career path for a Cement Fittings Maker?

With experience, Cement Fittings Makers can advance to positions such as Production Supervisor, Quality Control Manager, or Plant Manager.

What are the educational requirements to become a Cement Fittings Maker?

A high school diploma or equivalent is typically required, although some employers may prefer candidates with a college degree in a related field, such as civil engineering or construction management.

What is the average salary for a Cement Fittings Maker?

The average salary for a Cement Fittings Maker in the United States is around $45,000 per year.

What are the job outlook and employment prospects for Cement Fittings Makers?

The job outlook for Cement Fittings Makers is expected to be good over the next decade, with an increase in demand for construction projects.

What are the working conditions for Cement Fittings Makers?

Cement Fittings Makers typically work in factories or construction sites, and may be exposed to dust, noise, and chemicals.