Are you a seasoned Center Punch Operator seeking a new career path? Discover our professionally built Center Punch Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

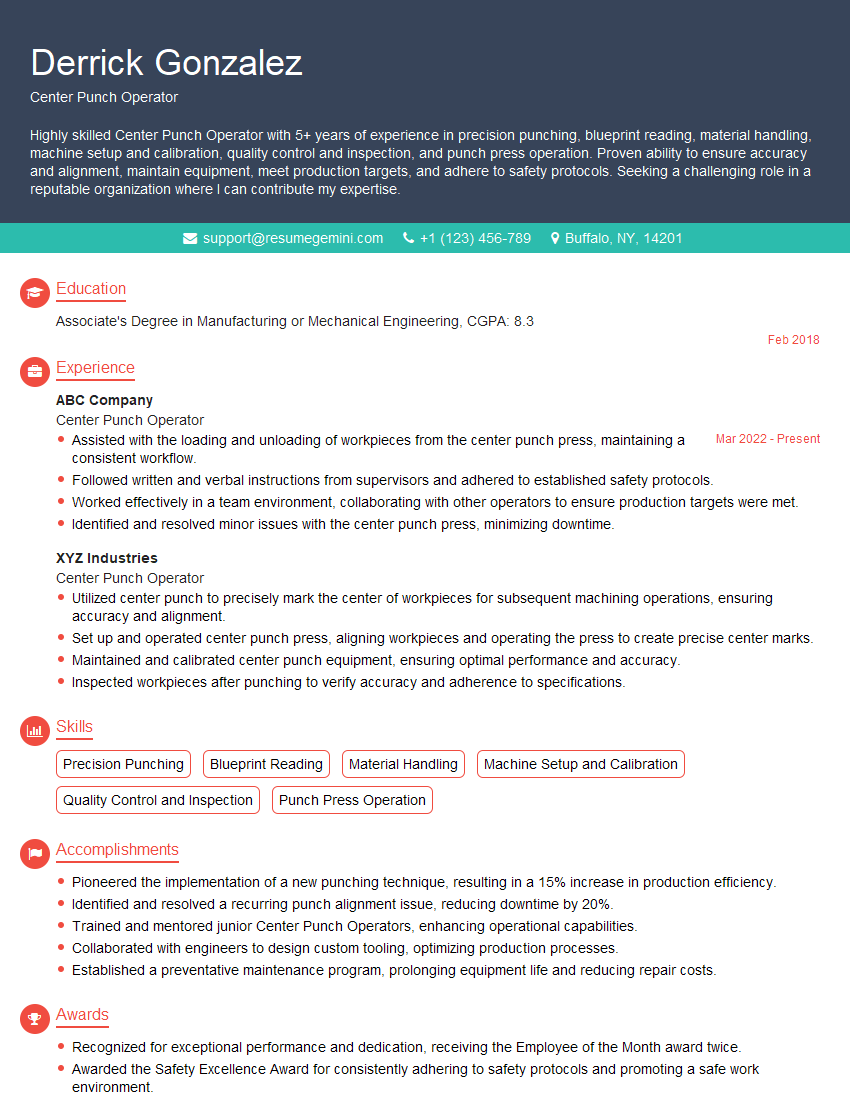

Derrick Gonzalez

Center Punch Operator

Summary

Highly skilled Center Punch Operator with 5+ years of experience in precision punching, blueprint reading, material handling, machine setup and calibration, quality control and inspection, and punch press operation. Proven ability to ensure accuracy and alignment, maintain equipment, meet production targets, and adhere to safety protocols. Seeking a challenging role in a reputable organization where I can contribute my expertise.

Education

Associate’s Degree in Manufacturing or Mechanical Engineering

February 2018

Skills

- Precision Punching

- Blueprint Reading

- Material Handling

- Machine Setup and Calibration

- Quality Control and Inspection

- Punch Press Operation

Work Experience

Center Punch Operator

- Assisted with the loading and unloading of workpieces from the center punch press, maintaining a consistent workflow.

- Followed written and verbal instructions from supervisors and adhered to established safety protocols.

- Worked effectively in a team environment, collaborating with other operators to ensure production targets were met.

- Identified and resolved minor issues with the center punch press, minimizing downtime.

Center Punch Operator

- Utilized center punch to precisely mark the center of workpieces for subsequent machining operations, ensuring accuracy and alignment.

- Set up and operated center punch press, aligning workpieces and operating the press to create precise center marks.

- Maintained and calibrated center punch equipment, ensuring optimal performance and accuracy.

- Inspected workpieces after punching to verify accuracy and adherence to specifications.

Accomplishments

- Pioneered the implementation of a new punching technique, resulting in a 15% increase in production efficiency.

- Identified and resolved a recurring punch alignment issue, reducing downtime by 20%.

- Trained and mentored junior Center Punch Operators, enhancing operational capabilities.

- Collaborated with engineers to design custom tooling, optimizing production processes.

- Established a preventative maintenance program, prolonging equipment life and reducing repair costs.

Awards

- Recognized for exceptional performance and dedication, receiving the Employee of the Month award twice.

- Awarded the Safety Excellence Award for consistently adhering to safety protocols and promoting a safe work environment.

- Recognized for outstanding safety performance, receiving the Safety Star award for maintaining an accidentfree work environment.

Certificates

- Certified Punch Press Operator

- OSHA Safety Certification

- Lean Manufacturing Certification

- ISO 9001:2015 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Center Punch Operator

- Highlight your precision punching skills and experience in operating center punch presses.

- Demonstrate your knowledge of blueprint reading and ability to set up and calibrate machines.

- Emphasize your attention to detail and commitment to quality control.

- Quantify your accomplishments whenever possible to demonstrate your impact on production and efficiency.

- Showcase your teamwork abilities and willingness to collaborate with others.

Essential Experience Highlights for a Strong Center Punch Operator Resume

- Utilized center punch to precisely mark the center of workpieces for subsequent machining operations, ensuring accuracy and alignment.

- Set up and operated center punch press, aligning workpieces and operating the press to create precise center marks.

- Maintained and calibrated center punch equipment, ensuring optimal performance and accuracy.

- Inspected workpieces after punching to verify accuracy and adherence to specifications.

- Assisted with the loading and unloading of workpieces from the center punch press, maintaining a consistent workflow.

- Followed written and verbal instructions from supervisors and adhered to established safety protocols.

- Worked effectively in a team environment, collaborating with other operators to ensure production targets were met.

- Identified and resolved minor issues with the center punch press, minimizing downtime.

Frequently Asked Questions (FAQ’s) For Center Punch Operator

What is the primary function of a Center Punch Operator?

The primary function of a Center Punch Operator is to use a center punch to precisely mark the center of workpieces for subsequent machining operations, ensuring accuracy and alignment.

What skills are essential for a Center Punch Operator?

Essential skills for a Center Punch Operator include precision punching, blueprint reading, material handling, machine setup and calibration, quality control and inspection, punch press operation, and adherence to safety protocols.

What industries employ Center Punch Operators?

Center Punch Operators are employed in a variety of industries, including manufacturing, automotive, and aerospace.

What are the career growth opportunities for Center Punch Operators?

Center Punch Operators can advance to positions such as Quality Control Inspector, Machine Setup Operator, or Supervisor.

What is the average salary range for Center Punch Operators?

The average salary range for Center Punch Operators varies depending on experience and location, but typically falls between $15-$25 per hour.

What are the safety precautions that Center Punch Operators should follow?

Center Punch Operators should wear appropriate safety gear, including gloves, safety glasses, and earplugs, and follow established safety protocols to prevent injuries.

What are the challenges faced by Center Punch Operators?

Center Punch Operators may face challenges such as working with small and delicate parts, maintaining accuracy and precision, and meeting production targets while adhering to safety regulations.

What is the future outlook for Center Punch Operators?

The future outlook for Center Punch Operators is expected to be stable, with demand for skilled operators in manufacturing and other industries.