Are you a seasoned Centerless Grinder seeking a new career path? Discover our professionally built Centerless Grinder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

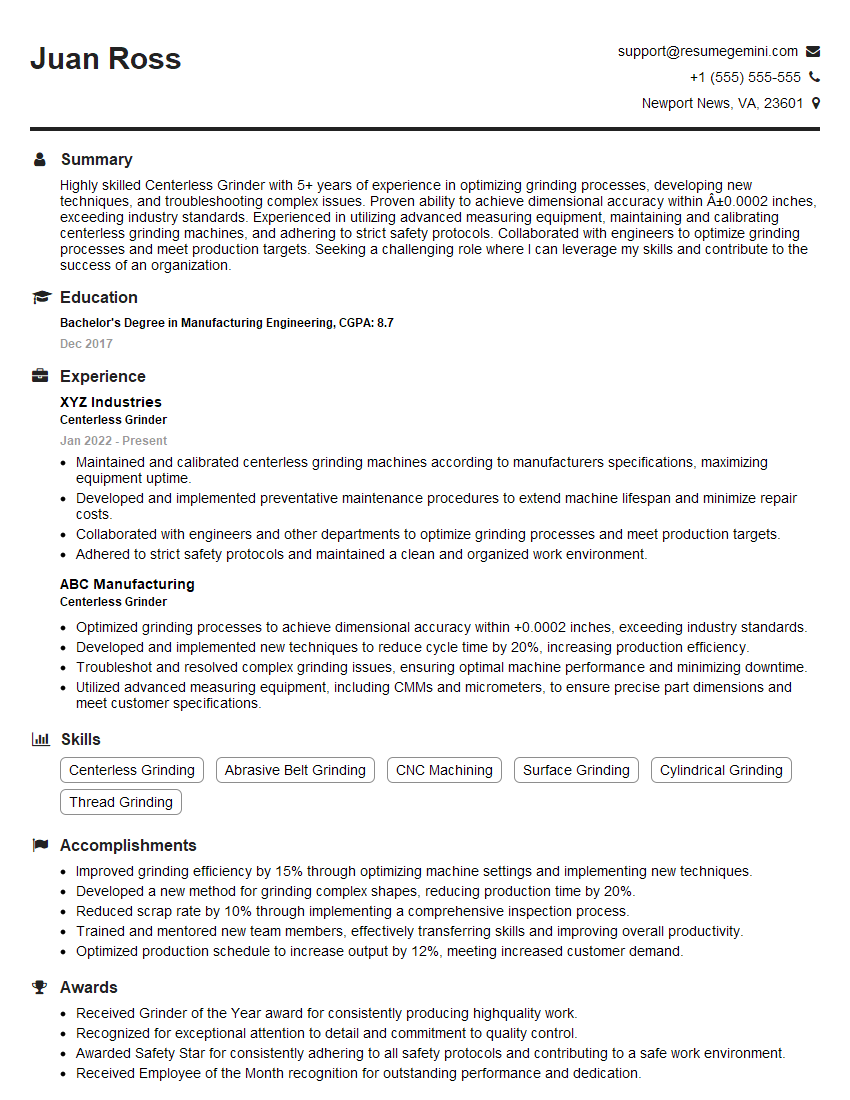

Juan Ross

Centerless Grinder

Summary

Highly skilled Centerless Grinder with 5+ years of experience in optimizing grinding processes, developing new techniques, and troubleshooting complex issues. Proven ability to achieve dimensional accuracy within ±0.0002 inches, exceeding industry standards. Experienced in utilizing advanced measuring equipment, maintaining and calibrating centerless grinding machines, and adhering to strict safety protocols. Collaborated with engineers to optimize grinding processes and meet production targets. Seeking a challenging role where I can leverage my skills and contribute to the success of an organization.

Education

Bachelor’s Degree in Manufacturing Engineering

December 2017

Skills

- Centerless Grinding

- Abrasive Belt Grinding

- CNC Machining

- Surface Grinding

- Cylindrical Grinding

- Thread Grinding

Work Experience

Centerless Grinder

- Maintained and calibrated centerless grinding machines according to manufacturers specifications, maximizing equipment uptime.

- Developed and implemented preventative maintenance procedures to extend machine lifespan and minimize repair costs.

- Collaborated with engineers and other departments to optimize grinding processes and meet production targets.

- Adhered to strict safety protocols and maintained a clean and organized work environment.

Centerless Grinder

- Optimized grinding processes to achieve dimensional accuracy within +0.0002 inches, exceeding industry standards.

- Developed and implemented new techniques to reduce cycle time by 20%, increasing production efficiency.

- Troubleshot and resolved complex grinding issues, ensuring optimal machine performance and minimizing downtime.

- Utilized advanced measuring equipment, including CMMs and micrometers, to ensure precise part dimensions and meet customer specifications.

Accomplishments

- Improved grinding efficiency by 15% through optimizing machine settings and implementing new techniques.

- Developed a new method for grinding complex shapes, reducing production time by 20%.

- Reduced scrap rate by 10% through implementing a comprehensive inspection process.

- Trained and mentored new team members, effectively transferring skills and improving overall productivity.

- Optimized production schedule to increase output by 12%, meeting increased customer demand.

Awards

- Received Grinder of the Year award for consistently producing highquality work.

- Recognized for exceptional attention to detail and commitment to quality control.

- Awarded Safety Star for consistently adhering to all safety protocols and contributing to a safe work environment.

- Received Employee of the Month recognition for outstanding performance and dedication.

Certificates

- Certified Centerless Grinder Operator

- National Institute for Metalworking Skills (NIMS) Certification

- Precision Grinding Certificate

- American Welding Society (AWS) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Centerless Grinder

- Highlight your skills and experience in optimizing grinding processes and achieving precise dimensional accuracy.

- Quantify your accomplishments with specific metrics, such as reducing cycle time or increasing production efficiency.

- Showcase your ability to troubleshoot and resolve complex grinding issues.

- Demonstrate your proficiency in using advanced measuring equipment and maintaining and calibrating centerless grinding machines.

- Emphasize your commitment to safety and maintaining a clean and organized work environment.

Essential Experience Highlights for a Strong Centerless Grinder Resume

- Optimized grinding processes to achieve dimensional accuracy within +0.0002 inches, exceeding industry standards.

- Developed and implemented new techniques to reduce cycle time by 20%, increasing production efficiency.

- Troubleshot and resolved complex grinding issues, ensuring optimal machine performance and minimizing downtime.

- Utilized advanced measuring equipment, including CMMs and micrometers, to ensure precise part dimensions and meet customer specifications.

- Maintained and calibrated centerless grinding machines according to manufacturers specifications, maximizing equipment uptime.

- Developed and implemented preventative maintenance procedures to extend machine lifespan and minimize repair costs.

- Collaborated with engineers and other departments to optimize grinding processes and meet production targets.

- Adhered to strict safety protocols and maintained a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Centerless Grinder

What is the primary role of a Centerless Grinder?

A Centerless Grinder operates specialized machinery to grind cylindrical workpieces without the use of centers or chucks, ensuring precise dimensions and surface finishes.

What skills are essential for a Centerless Grinder?

Essential skills include expertise in centerless grinding techniques, proficiency in operating CNC machines, understanding of grinding wheel selection and dressing, and adherence to safety protocols.

What industries commonly employ Centerless Grinders?

Centerless Grinders find employment in various industries, including automotive, aerospace, manufacturing, and metalworking.

What are the career advancement opportunities for a Centerless Grinder?

With experience and additional training, Centerless Grinders can advance to roles such as Supervisor, Production Manager, or Quality Control Inspector.

What safety precautions should a Centerless Grinder observe?

Centerless Grinders must wear appropriate safety gear, follow established safety procedures, and be cautious of potential hazards such as rotating machinery and flying sparks.

How does continuous improvement impact the role of a Centerless Grinder?

Centerless Grinders are expected to embrace continuous improvement initiatives, such as implementing new techniques to enhance efficiency and minimize waste.