Are you a seasoned Centrifugal Casting Machine Operator seeking a new career path? Discover our professionally built Centrifugal Casting Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

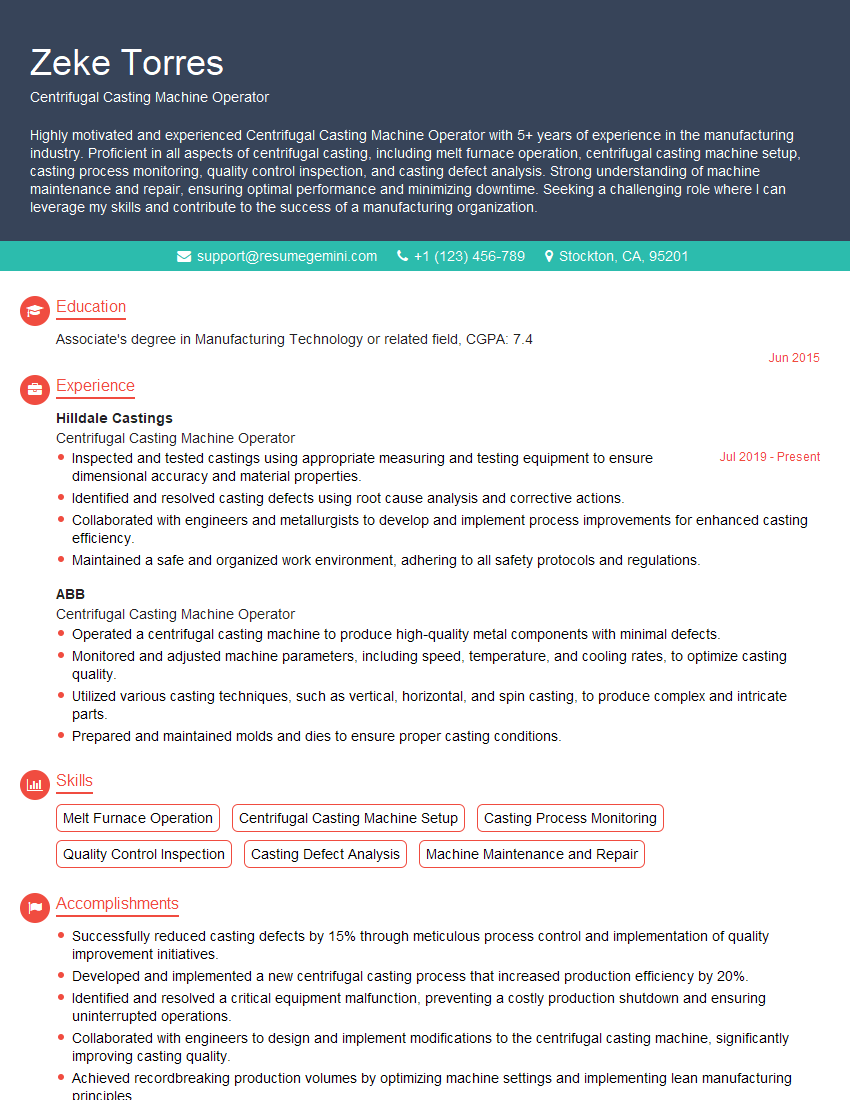

Zeke Torres

Centrifugal Casting Machine Operator

Summary

Highly motivated and experienced Centrifugal Casting Machine Operator with 5+ years of experience in the manufacturing industry. Proficient in all aspects of centrifugal casting, including melt furnace operation, centrifugal casting machine setup, casting process monitoring, quality control inspection, and casting defect analysis. Strong understanding of machine maintenance and repair, ensuring optimal performance and minimizing downtime. Seeking a challenging role where I can leverage my skills and contribute to the success of a manufacturing organization.

Education

Associate’s degree in Manufacturing Technology or related field

June 2015

Skills

- Melt Furnace Operation

- Centrifugal Casting Machine Setup

- Casting Process Monitoring

- Quality Control Inspection

- Casting Defect Analysis

- Machine Maintenance and Repair

Work Experience

Centrifugal Casting Machine Operator

- Inspected and tested castings using appropriate measuring and testing equipment to ensure dimensional accuracy and material properties.

- Identified and resolved casting defects using root cause analysis and corrective actions.

- Collaborated with engineers and metallurgists to develop and implement process improvements for enhanced casting efficiency.

- Maintained a safe and organized work environment, adhering to all safety protocols and regulations.

Centrifugal Casting Machine Operator

- Operated a centrifugal casting machine to produce high-quality metal components with minimal defects.

- Monitored and adjusted machine parameters, including speed, temperature, and cooling rates, to optimize casting quality.

- Utilized various casting techniques, such as vertical, horizontal, and spin casting, to produce complex and intricate parts.

- Prepared and maintained molds and dies to ensure proper casting conditions.

Accomplishments

- Successfully reduced casting defects by 15% through meticulous process control and implementation of quality improvement initiatives.

- Developed and implemented a new centrifugal casting process that increased production efficiency by 20%.

- Identified and resolved a critical equipment malfunction, preventing a costly production shutdown and ensuring uninterrupted operations.

- Collaborated with engineers to design and implement modifications to the centrifugal casting machine, significantly improving casting quality.

- Achieved recordbreaking production volumes by optimizing machine settings and implementing lean manufacturing principles.

Awards

- Recipient of the Excellence in Centrifugal Casting award for outstanding performance in operating and maintaining centrifugal casting machines.

- Awarded the Centrifugal Casting Machine Operator of the Year for demonstrating exceptional skills and achieving exceptional production targets.

- Received the Safety Excellence Award for maintaining an exemplary safety record and implementing effective safety protocols.

- Recognized for exceptional troubleshooting skills, consistently resolving complex casting issues and optimizing machine performance.

Certificates

- Centrifugal Casting Operator Certification

- Quality Control Certification

- Occupational Safety and Health Administration (OSHA) Certification

- American Society for Metals (ASM) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Centrifugal Casting Machine Operator

- Highlight your experience operating centrifugal casting machines and quantifying your accomplishments with specific metrics.

- Showcase your knowledge of centrifugal casting processes, including metal preparation, mold design, and pouring techniques.

- Emphasize your ability to identify and troubleshoot casting defects, demonstrating your problem-solving skills.

- Include relevant certifications, such as the American Foundry Society’s Certified Casting Operator (CCO) credential.

- Proofread your resume carefully to ensure accuracy and professionalism.

Essential Experience Highlights for a Strong Centrifugal Casting Machine Operator Resume

- Operate centrifugal casting machines to produce high-quality castings according to specified requirements.

- Set up and calibrate centrifugal casting machines, ensuring optimal casting parameters and machine performance.

- Monitor casting process, adjust parameters, and troubleshoot any issues to ensure product quality.

- Inspect castings for defects, identify root causes, and implement corrective actions to improve casting quality.

- Maintain and repair centrifugal casting machines, perform routine maintenance tasks, and troubleshoot mechanical issues to minimize downtime.

- Follow safety protocols, wear appropriate personal protective equipment, and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Centrifugal Casting Machine Operator

What is the educational background required to become a Centrifugal Casting Machine Operator?

While a formal degree is not always required, employers typically prefer candidates with an Associate’s degree in Manufacturing Technology or a related field. Relevant coursework may include metalworking, casting processes, and machine operation.

What are the key skills and responsibilities of a Centrifugal Casting Machine Operator?

Key responsibilities include operating centrifugal casting machines, setting up and calibrating equipment, monitoring the casting process, inspecting castings for defects, and performing machine maintenance. Essential skills include knowledge of centrifugal casting processes, ability to identify and troubleshoot casting defects, and proficiency in machine operation and maintenance.

What industries employ Centrifugal Casting Machine Operators?

Centrifugal Casting Machine Operators are employed in various industries, including automotive, aerospace, construction, and manufacturing. They work in foundries, machine shops, and manufacturing facilities.

What are the career advancement opportunities for Centrifugal Casting Machine Operators?

Experienced Centrifugal Casting Machine Operators may advance to supervisory roles, such as Production Supervisor or Quality Control Manager. They may also pursue specialized training or certifications to enhance their skills and knowledge.

What is the job outlook for Centrifugal Casting Machine Operators?

The job outlook for Centrifugal Casting Machine Operators is expected to be stable in the coming years, with a projected growth rate in line with the average for all occupations.

What are the challenges faced by Centrifugal Casting Machine Operators?

Centrifugal Casting Machine Operators may face challenges related to working with molten metal, operating heavy machinery, and meeting production targets. They must also be able to work in a fast-paced environment and pay attention to detail to ensure product quality.