Are you a seasoned Certified Maintenance Welder seeking a new career path? Discover our professionally built Certified Maintenance Welder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

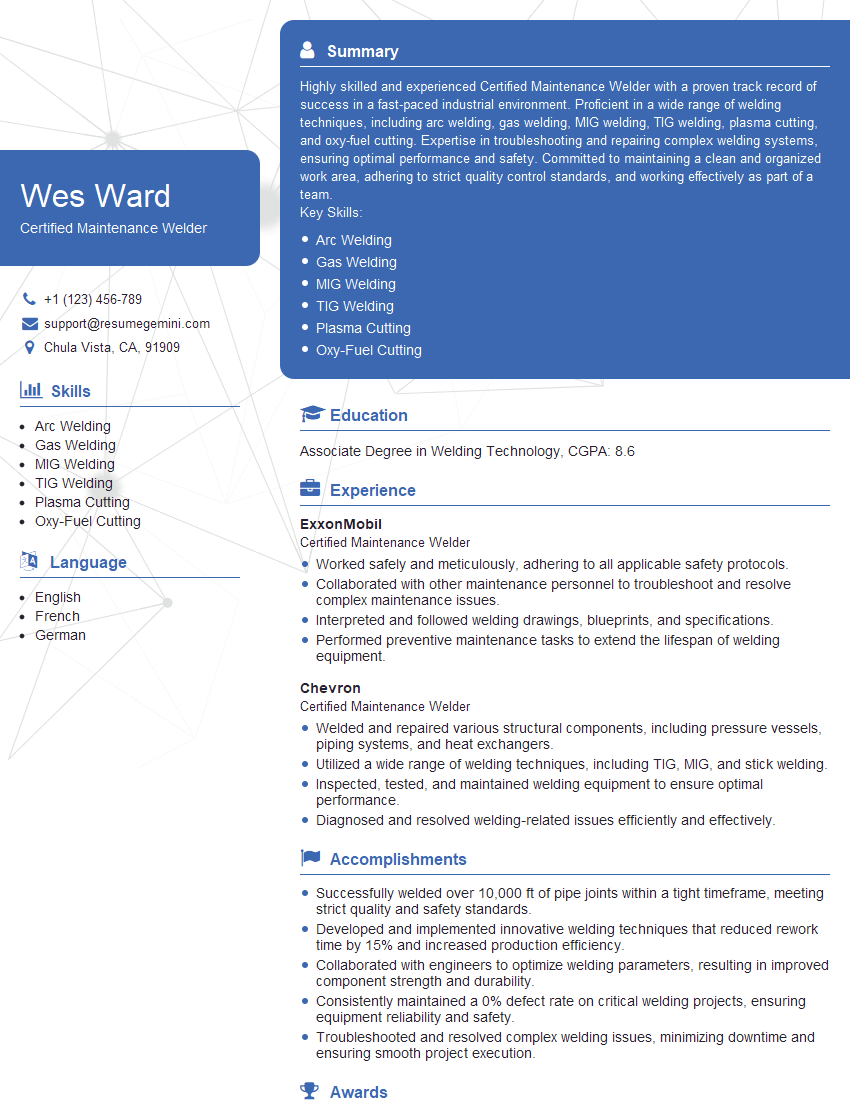

Wes Ward

Certified Maintenance Welder

Summary

Highly skilled and experienced Certified Maintenance Welder with a proven track record of success in a fast-paced industrial environment. Proficient in a wide range of welding techniques, including arc welding, gas welding, MIG welding, TIG welding, plasma cutting, and oxy-fuel cutting. Expertise in troubleshooting and repairing complex welding systems, ensuring optimal performance and safety. Committed to maintaining a clean and organized work area, adhering to strict quality control standards, and working effectively as part of a team.

Key Skills:

- Arc Welding

- Gas Welding

- MIG Welding

- TIG Welding

- Plasma Cutting

- Oxy-Fuel Cutting

Education

Associate Degree in Welding Technology

October 2016

Skills

- Arc Welding

- Gas Welding

- MIG Welding

- TIG Welding

- Plasma Cutting

- Oxy-Fuel Cutting

Work Experience

Certified Maintenance Welder

- Worked safely and meticulously, adhering to all applicable safety protocols.

- Collaborated with other maintenance personnel to troubleshoot and resolve complex maintenance issues.

- Interpreted and followed welding drawings, blueprints, and specifications.

- Performed preventive maintenance tasks to extend the lifespan of welding equipment.

Certified Maintenance Welder

- Welded and repaired various structural components, including pressure vessels, piping systems, and heat exchangers.

- Utilized a wide range of welding techniques, including TIG, MIG, and stick welding.

- Inspected, tested, and maintained welding equipment to ensure optimal performance.

- Diagnosed and resolved welding-related issues efficiently and effectively.

Accomplishments

- Successfully welded over 10,000 ft of pipe joints within a tight timeframe, meeting strict quality and safety standards.

- Developed and implemented innovative welding techniques that reduced rework time by 15% and increased production efficiency.

- Collaborated with engineers to optimize welding parameters, resulting in improved component strength and durability.

- Consistently maintained a 0% defect rate on critical welding projects, ensuring equipment reliability and safety.

- Troubleshooted and resolved complex welding issues, minimizing downtime and ensuring smooth project execution.

Awards

- Awarded Welder of the Year by the American Welding Society (AWS) for exceptional welding skills and contributions to the welding industry.

- Received the Excellence in Welding award from the National Institute for Metalworking Skills (NIMS) for achieving the highest level of welding proficiency.

- Recognized as a Master Welder by the Canadian Welding Bureau (CWB) for demonstrating superior welding abilities and adhering to industry standards.

Certificates

- AWS Certified Welder

- ASME Section IX Welder

- ASME B31.3 Welder

- OSHA 30-Hour Hazardous Waste Operations and Emergency Response

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Certified Maintenance Welder

Highlight your welding certifications and experience.

Showcase your problem-solving and troubleshooting skills.

Quantify your accomplishments using specific metrics.

Tailor your resume to each job you apply for.

Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Certified Maintenance Welder Resume

- Perform scheduled and unscheduled maintenance and repairs on welding equipment, including welders, power sources, and torches.

- Troubleshoot and diagnose welding system malfunctions, identify root causes, and implement effective solutions.

- Fabricate and repair metal components, structures, and piping systems according to engineering specifications and drawings.

- Inspect and test welds to ensure they meet quality standards and comply with industry codes.

- Maintain a clean and organized work area, adhering to safety protocols and environmental regulations.

- Provide technical support and guidance to colleagues and assist in training new welders.

- Stay up-to-date on the latest welding techniques and industry best practices.

Frequently Asked Questions (FAQ’s) For Certified Maintenance Welder

What is a Certified Maintenance Welder?

A Certified Maintenance Welder is a skilled professional responsible for maintaining and repairing welding equipment and systems in industrial settings. They possess expertise in various welding techniques and have the ability to diagnose and resolve complex welding issues.

What are the key skills required for a Certified Maintenance Welder?

Essential skills for a Certified Maintenance Welder include proficiency in arc welding, gas welding, MIG welding, TIG welding, plasma cutting, and oxy-fuel cutting. They must also have strong troubleshooting and problem-solving abilities, as well as a solid understanding of welding codes and standards.

What is the job outlook for Certified Maintenance Welders?

The job outlook for Certified Maintenance Welders is expected to be favorable in the coming years due to the increasing demand for skilled welders in various industries, including construction, manufacturing, and energy.

What are the career advancement opportunities for Certified Maintenance Welders?

Certified Maintenance Welders can advance their careers by gaining experience and expertise in specialized welding techniques, such as underwater welding or robotic welding. They can also pursue management roles or become welding inspectors or instructors.

What is the average salary for a Certified Maintenance Welder?

The average salary for a Certified Maintenance Welder can vary depending on factors such as experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for welders, cutters, solderers, and brazers was around $47,000 in May 2021.

What are the benefits of becoming a Certified Maintenance Welder?

Becoming a Certified Maintenance Welder offers several benefits, including increased job opportunities, higher earning potential, and enhanced credibility within the welding industry. Certification demonstrates a welder’s skills and knowledge and can open doors to specialized roles and projects.