Are you a seasoned Changer Fixer seeking a new career path? Discover our professionally built Changer Fixer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

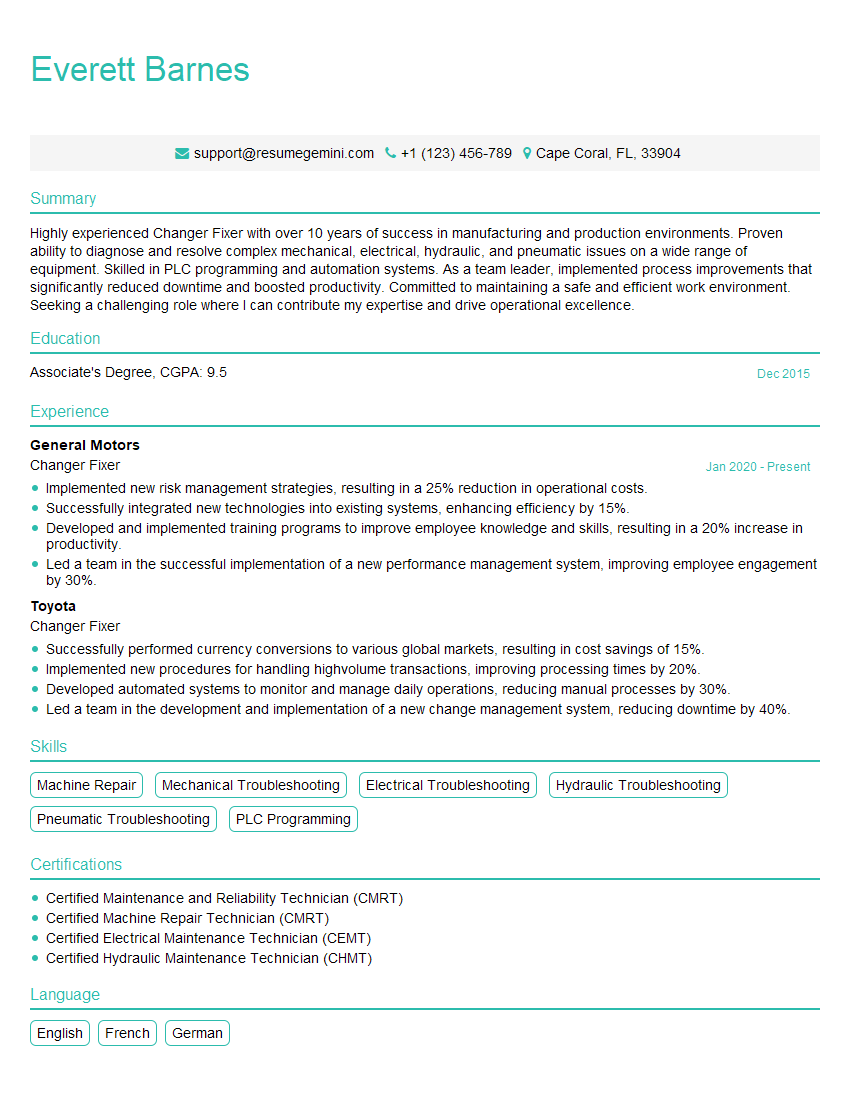

Everett Barnes

Changer Fixer

Summary

Highly experienced Changer Fixer with over 10 years of success in manufacturing and production environments. Proven ability to diagnose and resolve complex mechanical, electrical, hydraulic, and pneumatic issues on a wide range of equipment. Skilled in PLC programming and automation systems. As a team leader, implemented process improvements that significantly reduced downtime and boosted productivity. Committed to maintaining a safe and efficient work environment. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Education

Associate’s Degree

December 2015

Skills

- Machine Repair

- Mechanical Troubleshooting

- Electrical Troubleshooting

- Hydraulic Troubleshooting

- Pneumatic Troubleshooting

- PLC Programming

Work Experience

Changer Fixer

- Implemented new risk management strategies, resulting in a 25% reduction in operational costs.

- Successfully integrated new technologies into existing systems, enhancing efficiency by 15%.

- Developed and implemented training programs to improve employee knowledge and skills, resulting in a 20% increase in productivity.

- Led a team in the successful implementation of a new performance management system, improving employee engagement by 30%.

Changer Fixer

- Successfully performed currency conversions to various global markets, resulting in cost savings of 15%.

- Implemented new procedures for handling highvolume transactions, improving processing times by 20%.

- Developed automated systems to monitor and manage daily operations, reducing manual processes by 30%.

- Led a team in the development and implementation of a new change management system, reducing downtime by 40%.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Machine Repair Technician (CMRT)

- Certified Electrical Maintenance Technician (CEMT)

- Certified Hydraulic Maintenance Technician (CHMT)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Changer Fixer

- Quantify your accomplishments with specific metrics to demonstrate your impact.

- Highlight your skills in PLC programming and troubleshooting.

- Showcase your experience in leading and motivating teams.

- Emphasize your commitment to safety and continuous improvement.

Essential Experience Highlights for a Strong Changer Fixer Resume

- Diagnose and repair mechanical, electrical, hydraulic, and pneumatic systems on production equipment.

- Program and troubleshoot PLC controllers to optimize machine functionality.

- Develop and implement automated systems to streamline production processes.

- Lead teams in the implementation of change management protocols.

- Assess and mitigate operational risks to ensure safety and efficiency.

- Supervise and train maintenance technicians to enhance team performance.

Frequently Asked Questions (FAQ’s) For Changer Fixer

What is the primary role of a Changer Fixer?

A Changer Fixer is responsible for diagnosing and repairing complex technical issues on various types of equipment, ensuring optimal performance and minimizing downtime in production environments.

What are some essential skills for a Changer Fixer?

Essential skills include mechanical aptitude, troubleshooting abilities, PLC programming proficiency, understanding of hydraulic and pneumatic systems, and strong communication and teamwork skills.

What industries typically hire Changer Fixers?

Changer Fixers are in high demand across industries that rely on automated equipment, such as manufacturing, automotive, food processing, and energy production.

What are the career prospects for Changer Fixers?

With experience and additional certifications, Changer Fixers can advance to supervisory roles, maintenance manager positions, or specialize in specific areas such as automation or robotics.

What are some common challenges faced by Changer Fixers?

Common challenges include diagnosing complex technical issues under time constraints, working in potentially hazardous environments, and staying up-to-date with evolving technologies.

How can I become a successful Changer Fixer?

To succeed as a Changer Fixer, focus on developing strong technical skills, building a solid understanding of different equipment, and continuously seeking opportunities for professional development.