Are you a seasoned Chemical Etching Processor seeking a new career path? Discover our professionally built Chemical Etching Processor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

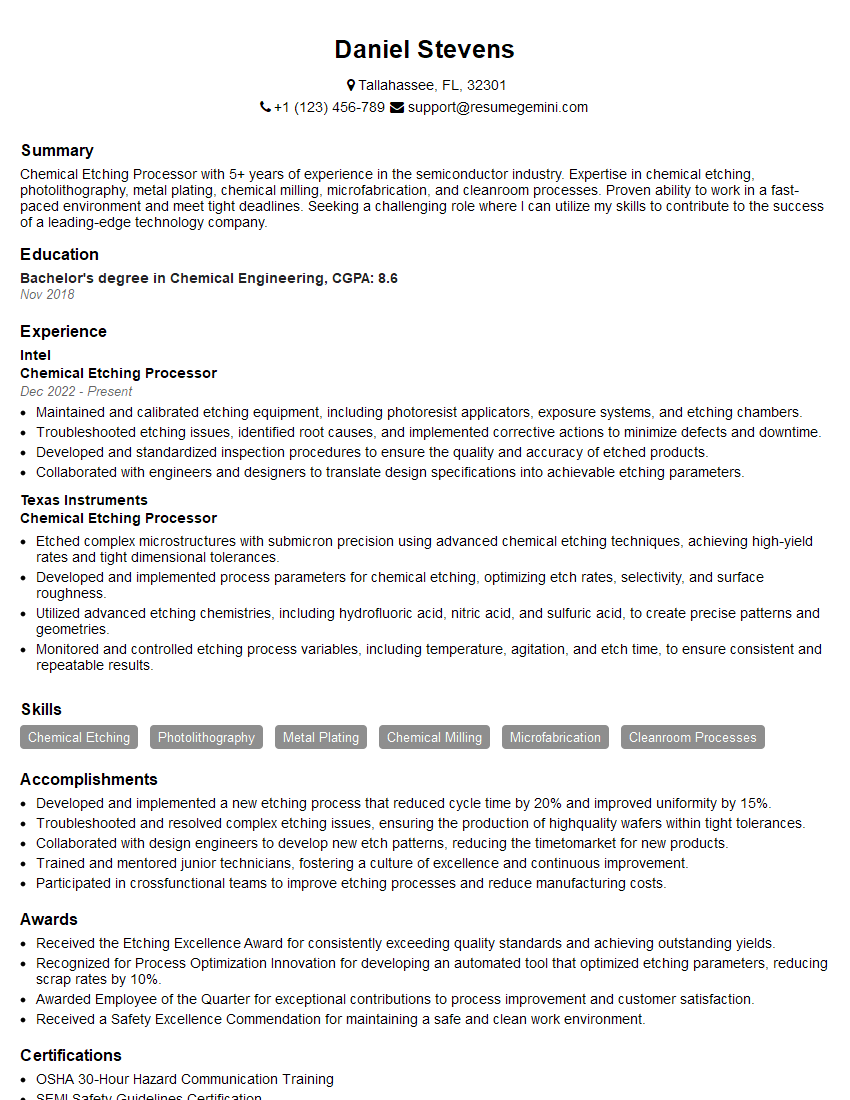

Daniel Stevens

Chemical Etching Processor

Summary

Chemical Etching Processor with 5+ years of experience in the semiconductor industry. Expertise in chemical etching, photolithography, metal plating, chemical milling, microfabrication, and cleanroom processes. Proven ability to work in a fast-paced environment and meet tight deadlines. Seeking a challenging role where I can utilize my skills to contribute to the success of a leading-edge technology company.

Education

Bachelor’s degree in Chemical Engineering

November 2018

Skills

- Chemical Etching

- Photolithography

- Metal Plating

- Chemical Milling

- Microfabrication

- Cleanroom Processes

Work Experience

Chemical Etching Processor

- Maintained and calibrated etching equipment, including photoresist applicators, exposure systems, and etching chambers.

- Troubleshooted etching issues, identified root causes, and implemented corrective actions to minimize defects and downtime.

- Developed and standardized inspection procedures to ensure the quality and accuracy of etched products.

- Collaborated with engineers and designers to translate design specifications into achievable etching parameters.

Chemical Etching Processor

- Etched complex microstructures with submicron precision using advanced chemical etching techniques, achieving high-yield rates and tight dimensional tolerances.

- Developed and implemented process parameters for chemical etching, optimizing etch rates, selectivity, and surface roughness.

- Utilized advanced etching chemistries, including hydrofluoric acid, nitric acid, and sulfuric acid, to create precise patterns and geometries.

- Monitored and controlled etching process variables, including temperature, agitation, and etch time, to ensure consistent and repeatable results.

Accomplishments

- Developed and implemented a new etching process that reduced cycle time by 20% and improved uniformity by 15%.

- Troubleshooted and resolved complex etching issues, ensuring the production of highquality wafers within tight tolerances.

- Collaborated with design engineers to develop new etch patterns, reducing the timetomarket for new products.

- Trained and mentored junior technicians, fostering a culture of excellence and continuous improvement.

- Participated in crossfunctional teams to improve etching processes and reduce manufacturing costs.

Awards

- Received the Etching Excellence Award for consistently exceeding quality standards and achieving outstanding yields.

- Recognized for Process Optimization Innovation for developing an automated tool that optimized etching parameters, reducing scrap rates by 10%.

- Awarded Employee of the Quarter for exceptional contributions to process improvement and customer satisfaction.

- Received a Safety Excellence Commendation for maintaining a safe and clean work environment.

Certificates

- OSHA 30-Hour Hazard Communication Training

- SEMI Safety Guidelines Certification

- ANSI/ESD S20.20 Certification

- IPC-6012 Certified Electronics Assembly Specialist

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Chemical Etching Processor

- Quantify your accomplishments with specific metrics whenever possible.

- Highlight your experience with different types of chemical etching equipment.

- Demonstrate your knowledge of cleanroom processes and safety protocols.

- Showcase your ability to work independently and as part of a team.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Chemical Etching Processor Resume

- Operate and maintain chemical etching equipment to produce high-quality semiconductor wafers.

- Develop and optimize chemical etching processes to improve yield and reduce cycle time.

- Troubleshoot and resolve process issues to ensure consistent product quality.

- Monitor and control process parameters to meet customer specifications.

- Perform preventive maintenance and calibration of equipment to ensure optimal performance.

- Adhere to all safety and environmental regulations.

- Work effectively in a team environment and communicate effectively with colleagues and customers.

Frequently Asked Questions (FAQ’s) For Chemical Etching Processor

What is chemical etching?

Chemical etching is a process used to remove material from a substrate by exposing it to a chemical solution that dissolves the material.

What are the different types of chemical etching?

There are two main types of chemical etching: isotropic etching and anisotropic etching. Isotropic etching removes material equally in all directions, while anisotropic etching removes material preferentially in certain directions.

What are the applications of chemical etching?

Chemical etching is used in a wide variety of applications, including the manufacture of semiconductors, printed circuit boards, and medical devices.

What are the safety precautions that should be taken when working with chemical etching?

Chemical etching can be hazardous, so it is important to take proper safety precautions. These precautions include wearing appropriate personal protective equipment, working in a well-ventilated area, and following all safety protocols.

What are the career opportunities for chemical etching processors?

Chemical etching processors can find work in a variety of industries, including the semiconductor industry, the printed circuit board industry, and the medical device industry. They can also work in research and development laboratories.

What is the salary range for chemical etching processors?

The salary range for chemical etching processors varies depending on their experience, skills, and location. According to Salary.com, the median annual salary for chemical etching processors in the United States is $65,000.