Are you a seasoned Chemical Plant Operator seeking a new career path? Discover our professionally built Chemical Plant Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

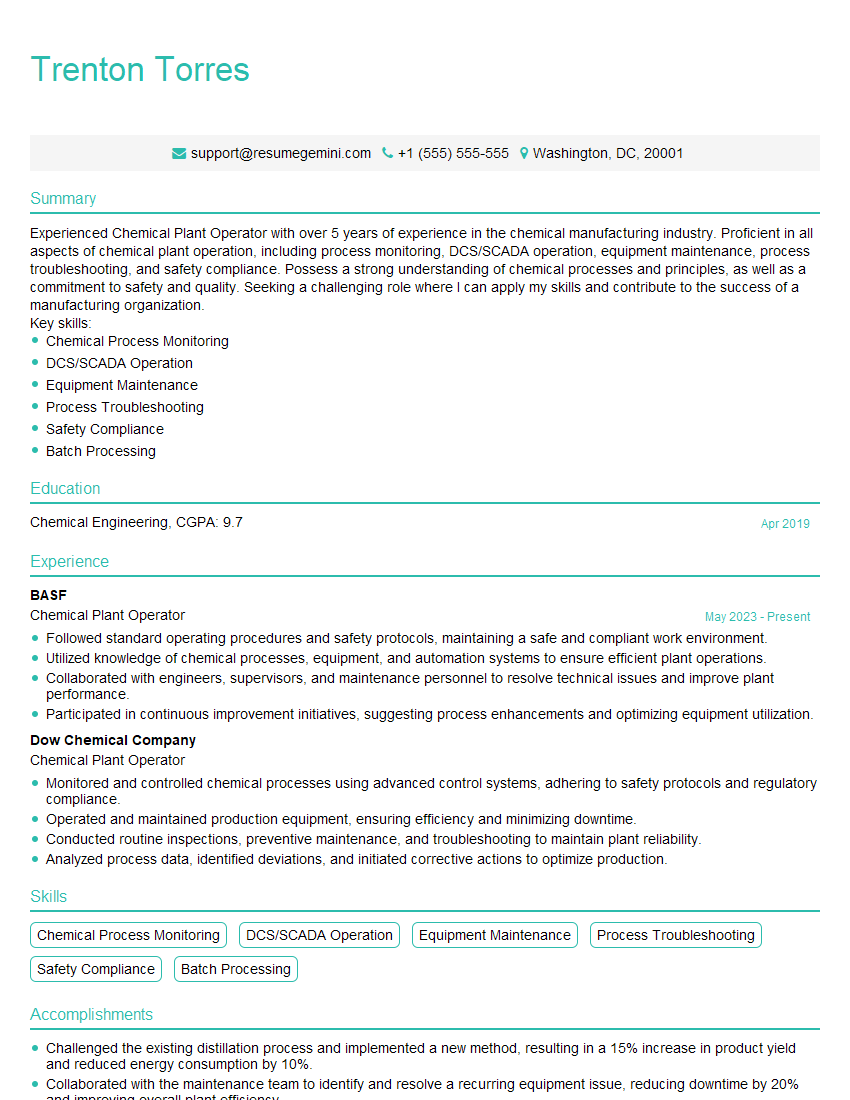

Trenton Torres

Chemical Plant Operator

Summary

Experienced Chemical Plant Operator with over 5 years of experience in the chemical manufacturing industry. Proficient in all aspects of chemical plant operation, including process monitoring, DCS/SCADA operation, equipment maintenance, process troubleshooting, and safety compliance. Possess a strong understanding of chemical processes and principles, as well as a commitment to safety and quality. Seeking a challenging role where I can apply my skills and contribute to the success of a manufacturing organization.

Key skills:

- Chemical Process Monitoring

- DCS/SCADA Operation

- Equipment Maintenance

- Process Troubleshooting

- Safety Compliance

- Batch Processing

Education

Chemical Engineering

April 2019

Skills

- Chemical Process Monitoring

- DCS/SCADA Operation

- Equipment Maintenance

- Process Troubleshooting

- Safety Compliance

- Batch Processing

Work Experience

Chemical Plant Operator

- Followed standard operating procedures and safety protocols, maintaining a safe and compliant work environment.

- Utilized knowledge of chemical processes, equipment, and automation systems to ensure efficient plant operations.

- Collaborated with engineers, supervisors, and maintenance personnel to resolve technical issues and improve plant performance.

- Participated in continuous improvement initiatives, suggesting process enhancements and optimizing equipment utilization.

Chemical Plant Operator

- Monitored and controlled chemical processes using advanced control systems, adhering to safety protocols and regulatory compliance.

- Operated and maintained production equipment, ensuring efficiency and minimizing downtime.

- Conducted routine inspections, preventive maintenance, and troubleshooting to maintain plant reliability.

- Analyzed process data, identified deviations, and initiated corrective actions to optimize production.

Accomplishments

- Challenged the existing distillation process and implemented a new method, resulting in a 15% increase in product yield and reduced energy consumption by 10%.

- Collaborated with the maintenance team to identify and resolve a recurring equipment issue, reducing downtime by 20% and improving overall plant efficiency.

- Spearheaded a team to develop and implement a comprehensive training program for new operators, ensuring a smooth onboarding process and enhanced plant safety.

- Analyzed plant data and identified potential process improvements, leading to a 7% reduction in raw material usage and corresponding cost savings.

- Developed a novel sampling technique to enhance process monitoring accuracy, enabling early detection and prevention of potential deviations.

Awards

- Safety Award for maintaining a spotless safety record for 3 consecutive years.

- Employee of the Quarter Award for exceptional performance in monitoring and controlling plant operations during a critical shutdown.

- Recognition for exceeding production targets by 120% while maintaining high quality standards.

- Safety Ambassador Award for consistently adhering to safety protocols and promoting a positive safety culture.

Certificates

- Certified Chemical Plant Operator (CCPO)

- Process Safety Management (PSM)

- Occupational Safety and Health Administration (OSHA)

- DOT Hazardous Materials Transportation

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Chemical Plant Operator

- Highlight your technical skills and experience in chemical plant operation, including process monitoring, DCS/SCADA operation, and equipment maintenance.

- Quantify your accomplishments with specific metrics, such as the number of processes you monitored, the amount of downtime you reduced, or the cost savings you achieved.

- Demonstrate your commitment to safety by mentioning your experience with safety protocols and regulations.

- Tailor your resume to each specific job you apply for by customizing your skills and experience to match the requirements of the position.

- Proofread your resume carefully before submitting it to ensure that there are no errors.

Essential Experience Highlights for a Strong Chemical Plant Operator Resume

- Monitored and controlled chemical processes to ensure optimal performance and product quality.

- Operated and maintained DCS/SCADA systems to monitor and control plant operations.

- Performed routine maintenance and repairs on plant equipment, including pumps, valves, and pipelines.

- Troubleshooted and resolved process problems to minimize downtime and maintain production efficiency.

- Ensured compliance with all safety regulations and procedures to protect personnel and the environment.

- Supervised and trained junior operators to ensure adherence to standard operating procedures.

- Collaborated with engineers and other plant personnel to improve plant operations and efficiency.

Frequently Asked Questions (FAQ’s) For Chemical Plant Operator

What is the primary role of a Chemical Plant Operator?

The primary role of a Chemical Plant Operator is to monitor and control chemical processes to ensure optimal performance and product quality. They operate and maintain DCS/SCADA systems, perform routine maintenance and repairs, troubleshoot and resolve process problems, and ensure compliance with all safety regulations and procedures.

What are the key skills required for a Chemical Plant Operator?

The key skills required for a Chemical Plant Operator include chemical process monitoring, DCS/SCADA operation, equipment maintenance, process troubleshooting, safety compliance, and batch processing.

What is the typical educational background of a Chemical Plant Operator?

The typical educational background of a Chemical Plant Operator is a degree in Chemical Engineering or a related field.

What are the career prospects for a Chemical Plant Operator?

The career prospects for a Chemical Plant Operator are good, with opportunities for advancement to supervisory or management positions. They can also specialize in specific areas, such as process optimization or safety.

What is the average salary for a Chemical Plant Operator?

The average salary for a Chemical Plant Operator in the United States is around $60,000 per year.

What are the working conditions like for a Chemical Plant Operator?

Chemical Plant Operators typically work in industrial settings, which can be noisy and hazardous. They may work long hours, including weekends and holidays.

What are the safety requirements for a Chemical Plant Operator?

Chemical Plant Operators must adhere to all safety regulations and procedures. They must wear appropriate personal protective equipment (PPE) and be trained in emergency response procedures.

What is the future outlook for the Chemical Plant Operator profession?

The future outlook for the Chemical Plant Operator profession is expected to be positive, with job growth projected to be faster than average.