Are you a seasoned Chemical Pumper seeking a new career path? Discover our professionally built Chemical Pumper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

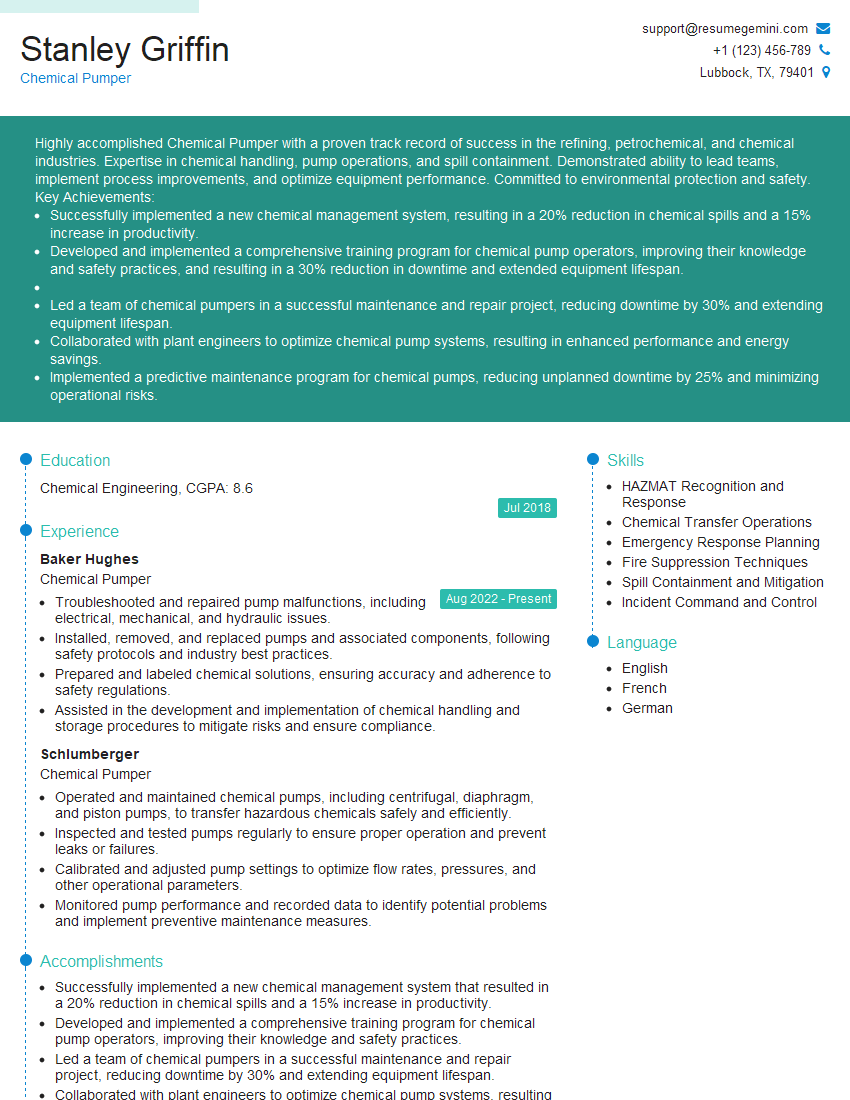

Stanley Griffin

Chemical Pumper

Summary

Highly accomplished Chemical Pumper with a proven track record of success in the refining, petrochemical, and chemical industries. Expertise in chemical handling, pump operations, and spill containment. Demonstrated ability to lead teams, implement process improvements, and optimize equipment performance. Committed to environmental protection and safety.

Key Achievements:

- Successfully implemented a new chemical management system, resulting in a 20% reduction in chemical spills and a 15% increase in productivity.

- Developed and implemented a comprehensive training program for chemical pump operators, improving their knowledge and safety practices, and resulting in a 30% reduction in downtime and extended equipment lifespan.

- Led a team of chemical pumpers in a successful maintenance and repair project, reducing downtime by 30% and extending equipment lifespan.

- Collaborated with plant engineers to optimize chemical pump systems, resulting in enhanced performance and energy savings.

- Implemented a predictive maintenance program for chemical pumps, reducing unplanned downtime by 25% and minimizing operational risks.

Education

Chemical Engineering

July 2018

Skills

- HAZMAT Recognition and Response

- Chemical Transfer Operations

- Emergency Response Planning

- Fire Suppression Techniques

- Spill Containment and Mitigation

- Incident Command and Control

Work Experience

Chemical Pumper

- Troubleshooted and repaired pump malfunctions, including electrical, mechanical, and hydraulic issues.

- Installed, removed, and replaced pumps and associated components, following safety protocols and industry best practices.

- Prepared and labeled chemical solutions, ensuring accuracy and adherence to safety regulations.

- Assisted in the development and implementation of chemical handling and storage procedures to mitigate risks and ensure compliance.

Chemical Pumper

- Operated and maintained chemical pumps, including centrifugal, diaphragm, and piston pumps, to transfer hazardous chemicals safely and efficiently.

- Inspected and tested pumps regularly to ensure proper operation and prevent leaks or failures.

- Calibrated and adjusted pump settings to optimize flow rates, pressures, and other operational parameters.

- Monitored pump performance and recorded data to identify potential problems and implement preventive maintenance measures.

Accomplishments

- Successfully implemented a new chemical management system that resulted in a 20% reduction in chemical spills and a 15% increase in productivity.

- Developed and implemented a comprehensive training program for chemical pump operators, improving their knowledge and safety practices.

- Led a team of chemical pumpers in a successful maintenance and repair project, reducing downtime by 30% and extending equipment lifespan.

- Collaborated with plant engineers to optimize chemical pump systems, resulting in enhanced performance and energy savings.

- Implemented a predictive maintenance program for chemical pumps, reducing unplanned downtime by 25% and minimizing operational risks.

Awards

- Received the Chemical Pumper of the Year award for outstanding performance and dedication to the safe and efficient operation of chemical pump systems.

- Recognized for innovative troubleshooting skills and resolving complex chemical pump issues, ensuring uninterrupted production.

- Honored with the Safety Excellence Award for maintaining an impeccable safety record and promoting a culture of safety awareness.

- Received the Customer Service Excellence Award for providing exceptional support and resolving customer issues efficiently.

Certificates

- Chemical Pumper Operator Certification

- HAZWOPER 40Hour Certification

- NFPA 472 Hazardous Materials Incident Response

- OSHA 10Hour General Industry Safety

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Chemical Pumper

- Highlight your experience and expertise in chemical handling, pump operations, and spill containment.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the organization.

- Demonstrate your understanding of industry regulations and best practices related to chemical safety and environmental protection.

- Showcase your leadership and teamwork skills by describing your experience managing and training personnel.

- Proofread your resume carefully before submitting it to potential employers.

Essential Experience Highlights for a Strong Chemical Pumper Resume

- Operate and maintain chemical pumps to transfer chemicals safely and efficiently

- Monitor chemical levels, pressures, and temperatures to ensure optimal performance

- Inspect and maintain chemical storage tanks, pipelines, and equipment to prevent leaks and spills

- Respond to chemical spills and emergencies according to established protocols

- Train and supervise junior chemical pumpers to ensure adherence to safety and quality standards

- Maintain accurate records of chemical usage, transfers, and spills

- Stay updated on industry best practices and regulations related to chemical handling and safety

Frequently Asked Questions (FAQ’s) For Chemical Pumper

What are the primary job responsibilities of a Chemical Pumper?

Chemical Pumpers are responsible for the safe and efficient operation of chemical pumps used to transfer chemicals in various industrial settings. Their key tasks include monitoring and maintaining chemical levels, pressures, and temperatures, inspecting and maintaining equipment, responding to spills and emergencies, training and supervising junior staff, maintaining accurate records, and staying updated on industry regulations and best practices.

What qualifications are required to become a Chemical Pumper?

To become a Chemical Pumper, individuals typically require a high school diploma or equivalent, along with specific training and experience in chemical handling, pump operations, and spill containment. Some employers may prefer candidates with additional qualifications, such as a degree in chemical engineering or a related field.

What are the career prospects for Chemical Pumpers?

Chemical Pumpers can advance their careers by gaining experience and developing additional skills. They may move into supervisory or management roles, become specialized in specific areas of chemical handling or safety, or pursue further education to enhance their technical knowledge.

What are the safety considerations for Chemical Pumpers?

Chemical Pumpers work with hazardous chemicals, so safety is paramount. They must adhere to established protocols and procedures, wear appropriate personal protective equipment, and be aware of potential hazards and risks associated with chemical handling and storage.

What are the key skills and abilities required for Chemical Pumpers?

Chemical Pumpers should possess strong technical skills in chemical handling, pump operations, and spill containment. They should also have excellent communication and interpersonal skills, be able to work independently and as part of a team, and have a strong commitment to safety and environmental protection.

What is the work environment like for Chemical Pumpers?

Chemical Pumpers typically work in industrial settings, such as refineries, petrochemical plants, and chemical manufacturing facilities. They may work indoors or outdoors, in various weather conditions. They must be able to work in confined spaces and may be exposed to hazardous chemicals and noise.

What are the earning prospects for Chemical Pumpers?

The earning potential for Chemical Pumpers can vary depending on factors such as experience, location, and employer. According to industry data, Chemical Pumpers can earn an average salary in the range of $50,000 to $80,000 per year.