Are you a seasoned Chip Person seeking a new career path? Discover our professionally built Chip Person Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

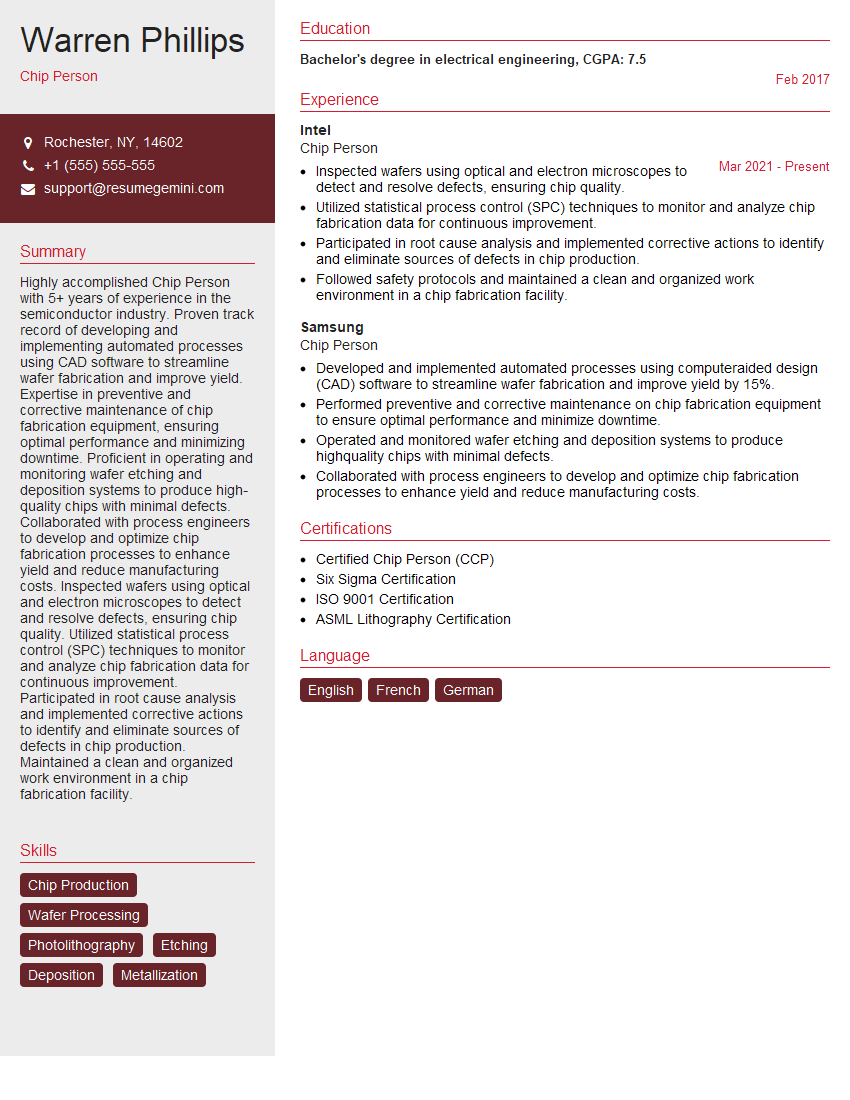

Warren Phillips

Chip Person

Summary

Highly accomplished Chip Person with 5+ years of experience in the semiconductor industry. Proven track record of developing and implementing automated processes using CAD software to streamline wafer fabrication and improve yield. Expertise in preventive and corrective maintenance of chip fabrication equipment, ensuring optimal performance and minimizing downtime. Proficient in operating and monitoring wafer etching and deposition systems to produce high-quality chips with minimal defects. Collaborated with process engineers to develop and optimize chip fabrication processes to enhance yield and reduce manufacturing costs. Inspected wafers using optical and electron microscopes to detect and resolve defects, ensuring chip quality. Utilized statistical process control (SPC) techniques to monitor and analyze chip fabrication data for continuous improvement. Participated in root cause analysis and implemented corrective actions to identify and eliminate sources of defects in chip production. Maintained a clean and organized work environment in a chip fabrication facility.

Education

Bachelor’s degree in electrical engineering

February 2017

Skills

- Chip Production

- Wafer Processing

- Photolithography

- Etching

- Deposition

- Metallization

Work Experience

Chip Person

- Inspected wafers using optical and electron microscopes to detect and resolve defects, ensuring chip quality.

- Utilized statistical process control (SPC) techniques to monitor and analyze chip fabrication data for continuous improvement.

- Participated in root cause analysis and implemented corrective actions to identify and eliminate sources of defects in chip production.

- Followed safety protocols and maintained a clean and organized work environment in a chip fabrication facility.

Chip Person

- Developed and implemented automated processes using computeraided design (CAD) software to streamline wafer fabrication and improve yield by 15%.

- Performed preventive and corrective maintenance on chip fabrication equipment to ensure optimal performance and minimize downtime.

- Operated and monitored wafer etching and deposition systems to produce highquality chips with minimal defects.

- Collaborated with process engineers to develop and optimize chip fabrication processes to enhance yield and reduce manufacturing costs.

Certificates

- Certified Chip Person (CCP)

- Six Sigma Certification

- ISO 9001 Certification

- ASML Lithography Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Chip Person

- Highlight your experience in developing and implementing automated processes using CAD software.

- Showcase your skills in preventive and corrective maintenance of chip fabrication equipment, ensuring optimal performance.

- Emphasize your expertise in operating and monitoring wafer etching and deposition systems to produce high-quality chips with minimal defects.

- Demonstrate your experience in collaborating with process engineers to develop and optimize chip fabrication processes to enhance yield and reduce manufacturing costs.

- Quantify your accomplishments with specific metrics and examples to demonstrate your impact on the organization.

Essential Experience Highlights for a Strong Chip Person Resume

- Developed and implemented automated processes using CAD software to streamline wafer fabrication and improve yield by 15%.

- Performed preventive and corrective maintenance on chip fabrication equipment to ensure optimal performance and minimize downtime.

- Operated and monitored wafer etching and deposition systems to produce high-quality chips with minimal defects.

- Collaborated with process engineers to develop and optimize chip fabrication processes to enhance yield and reduce manufacturing costs.

- Inspected wafers using optical and electron microscopes to detect and resolve defects, ensuring chip quality.

- Utilized statistical process control (SPC) techniques to monitor and analyze chip fabrication data for continuous improvement.

- Participated in root cause analysis and implemented corrective actions to identify and eliminate sources of defects in chip production.

Frequently Asked Questions (FAQ’s) For Chip Person

What is the role of a Chip Person?

A Chip Person is responsible for the fabrication of semiconductor chips, ensuring high-quality production and efficient processes.

What skills are required to be a successful Chip Person?

A Chip Person should possess expertise in chip production, wafer processing, photolithography, etching, deposition, and metallization.

What is the educational background required to become a Chip Person?

A Bachelor’s degree in electrical engineering or a related field is typically required to work as a Chip Person.

What are the career prospects for a Chip Person?

Chip Persons with experience and expertise can advance to roles such as Process Engineer, Quality Control Manager, or Production Supervisor.

What is the salary range for a Chip Person?

The salary range for a Chip Person varies depending on experience, qualifications, and location, but typically falls between $70,000 and $120,000 per year.

What are the challenges faced by Chip Persons in the semiconductor industry?

Chip Persons face challenges such as increasing demand for high-performance chips, rapid technological advancements, and the need for continuous improvement in yield and quality.