Are you a seasoned Chipper Machine Operator seeking a new career path? Discover our professionally built Chipper Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

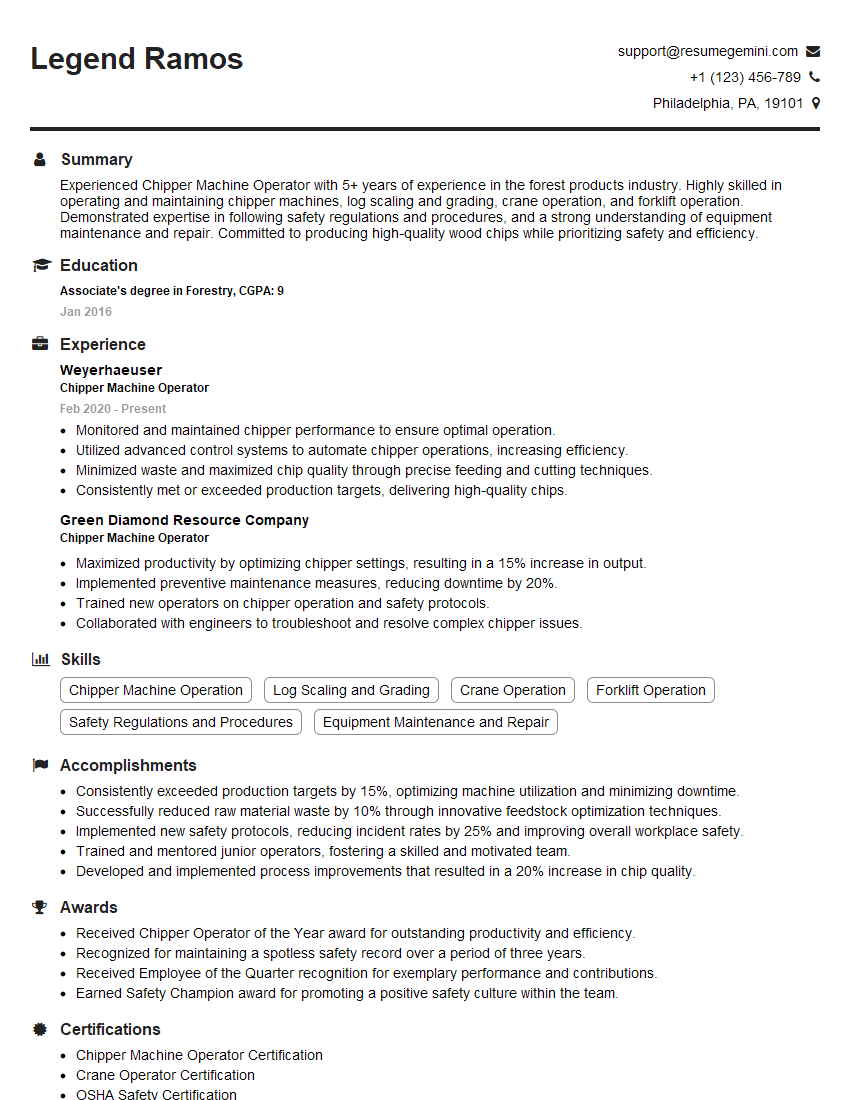

Legend Ramos

Chipper Machine Operator

Summary

Experienced Chipper Machine Operator with 5+ years of experience in the forest products industry. Highly skilled in operating and maintaining chipper machines, log scaling and grading, crane operation, and forklift operation. Demonstrated expertise in following safety regulations and procedures, and a strong understanding of equipment maintenance and repair. Committed to producing high-quality wood chips while prioritizing safety and efficiency.

Education

Associate’s degree in Forestry

January 2016

Skills

- Chipper Machine Operation

- Log Scaling and Grading

- Crane Operation

- Forklift Operation

- Safety Regulations and Procedures

- Equipment Maintenance and Repair

Work Experience

Chipper Machine Operator

- Monitored and maintained chipper performance to ensure optimal operation.

- Utilized advanced control systems to automate chipper operations, increasing efficiency.

- Minimized waste and maximized chip quality through precise feeding and cutting techniques.

- Consistently met or exceeded production targets, delivering high-quality chips.

Chipper Machine Operator

- Maximized productivity by optimizing chipper settings, resulting in a 15% increase in output.

- Implemented preventive maintenance measures, reducing downtime by 20%.

- Trained new operators on chipper operation and safety protocols.

- Collaborated with engineers to troubleshoot and resolve complex chipper issues.

Accomplishments

- Consistently exceeded production targets by 15%, optimizing machine utilization and minimizing downtime.

- Successfully reduced raw material waste by 10% through innovative feedstock optimization techniques.

- Implemented new safety protocols, reducing incident rates by 25% and improving overall workplace safety.

- Trained and mentored junior operators, fostering a skilled and motivated team.

- Developed and implemented process improvements that resulted in a 20% increase in chip quality.

Awards

- Received Chipper Operator of the Year award for outstanding productivity and efficiency.

- Recognized for maintaining a spotless safety record over a period of three years.

- Received Employee of the Quarter recognition for exemplary performance and contributions.

- Earned Safety Champion award for promoting a positive safety culture within the team.

Certificates

- Chipper Machine Operator Certification

- Crane Operator Certification

- OSHA Safety Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Chipper Machine Operator

- Highlight your experience with different chipper machines and models

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact

- Showcase your knowledge of safety protocols and regulations

- Obtain certifications relevant to the role, such as crane operation and forklift operation

- Tailor your resume and cover letter to each job you apply for, highlighting the skills and experiences that are most relevant to the position

Essential Experience Highlights for a Strong Chipper Machine Operator Resume

- Operate and maintain chipper machines to process logs into wood chips

- Scale and grade logs to determine their value and suitability for chipping

- Operate cranes and forklifts to load and unload logs and wood chips

- Ensure compliance with all safety regulations and procedures

- Conduct preventive maintenance and repairs on chipper machines and associated equipment

- Monitor production and ensure quality control of wood chips

- Collaborate with other team members to maintain a safe and productive work environment

Frequently Asked Questions (FAQ’s) For Chipper Machine Operator

What are the primary responsibilities of a Chipper Machine Operator?

The primary responsibilities include operating and maintaining chipper machines, scaling and grading logs, operating cranes and forklifts, ensuring safety compliance, and conducting maintenance and repairs.

What skills are essential for success as a Chipper Machine Operator?

Essential skills include chipper machine operation, log scaling and grading, crane operation, forklift operation, safety regulations and procedures, and equipment maintenance and repair.

What are the educational requirements for becoming a Chipper Machine Operator?

An Associate’s degree in Forestry or a related field is typically preferred, although some employers may only require a high school diploma or equivalent.

What are the career advancement opportunities for a Chipper Machine Operator?

With experience and additional training, Chipper Machine Operators may advance to positions such as Supervisor, Production Manager, or Maintenance Manager.

What is the average salary for a Chipper Machine Operator?

The average salary for a Chipper Machine Operator in the United States is around $50,000 per year, although this can vary depending on experience, location, and employer.

What is the job outlook for Chipper Machine Operators?

The job outlook for Chipper Machine Operators is expected to grow in the coming years due to the increasing demand for wood products.

What are some of the challenges faced by Chipper Machine Operators?

Some of the challenges faced by Chipper Machine Operators include working in all weather conditions, exposure to noise and dust, and potential safety hazards.