Are you a seasoned Chromium Plater seeking a new career path? Discover our professionally built Chromium Plater Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

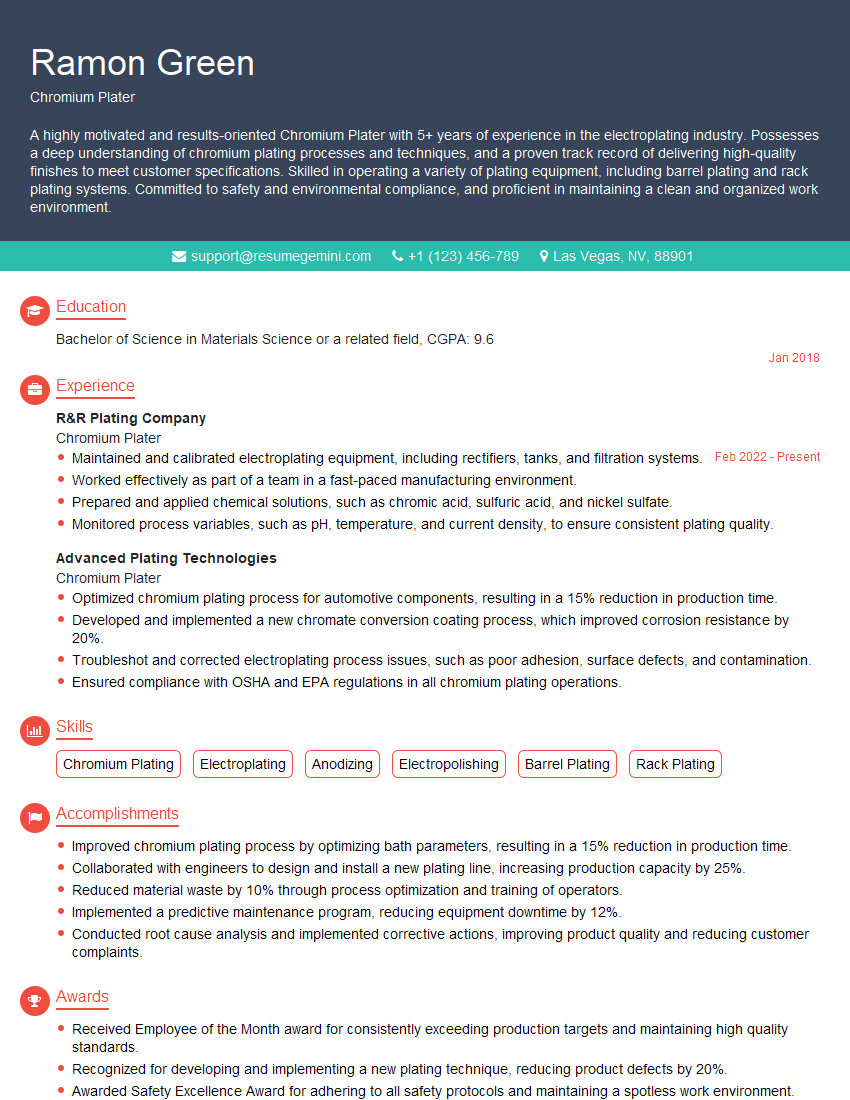

Ramon Green

Chromium Plater

Summary

A highly motivated and results-oriented Chromium Plater with 5+ years of experience in the electroplating industry. Possesses a deep understanding of chromium plating processes and techniques, and a proven track record of delivering high-quality finishes to meet customer specifications. Skilled in operating a variety of plating equipment, including barrel plating and rack plating systems. Committed to safety and environmental compliance, and proficient in maintaining a clean and organized work environment.

Education

Bachelor of Science in Materials Science or a related field

January 2018

Skills

- Chromium Plating

- Electroplating

- Anodizing

- Electropolishing

- Barrel Plating

- Rack Plating

Work Experience

Chromium Plater

- Maintained and calibrated electroplating equipment, including rectifiers, tanks, and filtration systems.

- Worked effectively as part of a team in a fast-paced manufacturing environment.

- Prepared and applied chemical solutions, such as chromic acid, sulfuric acid, and nickel sulfate.

- Monitored process variables, such as pH, temperature, and current density, to ensure consistent plating quality.

Chromium Plater

- Optimized chromium plating process for automotive components, resulting in a 15% reduction in production time.

- Developed and implemented a new chromate conversion coating process, which improved corrosion resistance by 20%.

- Troubleshot and corrected electroplating process issues, such as poor adhesion, surface defects, and contamination.

- Ensured compliance with OSHA and EPA regulations in all chromium plating operations.

Accomplishments

- Improved chromium plating process by optimizing bath parameters, resulting in a 15% reduction in production time.

- Collaborated with engineers to design and install a new plating line, increasing production capacity by 25%.

- Reduced material waste by 10% through process optimization and training of operators.

- Implemented a predictive maintenance program, reducing equipment downtime by 12%.

- Conducted root cause analysis and implemented corrective actions, improving product quality and reducing customer complaints.

Awards

- Received Employee of the Month award for consistently exceeding production targets and maintaining high quality standards.

- Recognized for developing and implementing a new plating technique, reducing product defects by 20%.

- Awarded Safety Excellence Award for adhering to all safety protocols and maintaining a spotless work environment.

- Received a Certificate of Excellence for outstanding performance in meeting and exceeding customer expectations.

Certificates

- Certified Electroplater

- Society of Vacuum Coaters

- National Association of Surface Finishers

- American Welding Society

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Chromium Plater

- Highlight your hands-on experience with chromium plating equipment and techniques.

- Quantify your accomplishments with specific metrics and results.

- Demonstrate your knowledge of safety and environmental regulations.

- Showcase your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Chromium Plater Resume

- Prepare and maintain electroplating solutions and equipment according to specified standards.

- Load and unload parts to and from plating racks and barrels.

- Monitor and adjust plating parameters to ensure proper coating thickness and adhesion.

- Inspect and test plated parts to verify compliance with specifications.

- Troubleshoot and resolve plating issues to minimize downtime and maintain production efficiency.

- Maintain a clean and organized work area, and follow all safety and environmental regulations.

- Collaborate with other team members to ensure smooth production operations.

Frequently Asked Questions (FAQ’s) For Chromium Plater

What is chromium plating?

Chromium plating is an electroplating process that applies a thin layer of chromium to a metal surface to enhance its corrosion resistance, wear resistance, and appearance.

What are the different types of chromium plating?

There are several types of chromium plating, including decorative, hard, and functional chromium plating.

What are the applications of chromium plating?

Chromium plating is used in a wide range of industries, including automotive, aerospace, and manufacturing, to protect and enhance metal surfaces.

What are the qualifications required to become a Chromium Plater?

Typically, a high school diploma or equivalent and experience in the electroplating industry is required. Some employers may prefer candidates with a degree in materials science or a related field.

What is the job outlook for Chromium Platers?

The job outlook for Chromium Platers is expected to be stable in the coming years, with growth driven by the increasing demand for corrosion-resistant and durable metal finishes.

What are the safety precautions that must be taken when working with chromium plating?

Chromium plating involves the use of hazardous chemicals and equipment, so it is essential to follow all safety precautions, including wearing appropriate personal protective equipment and adhering to established operating procedures.