Are you a seasoned Chute Puller seeking a new career path? Discover our professionally built Chute Puller Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

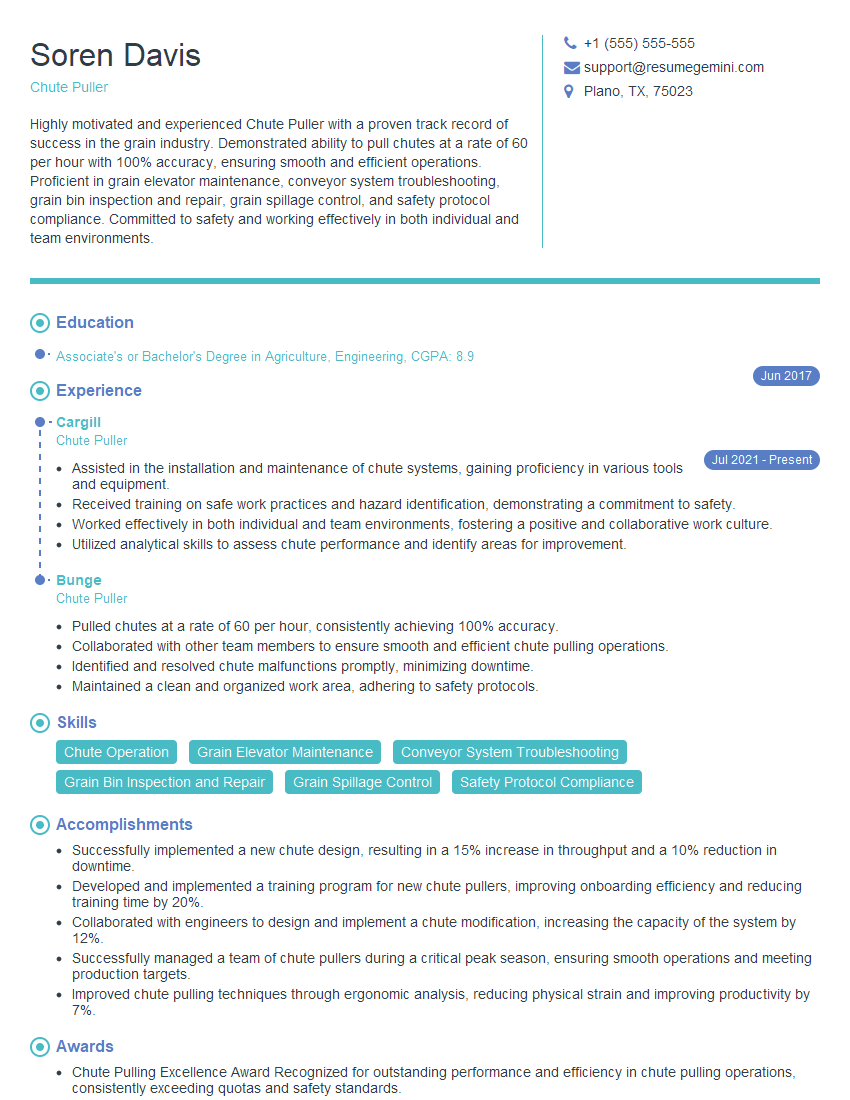

Soren Davis

Chute Puller

Summary

Highly motivated and experienced Chute Puller with a proven track record of success in the grain industry. Demonstrated ability to pull chutes at a rate of 60 per hour with 100% accuracy, ensuring smooth and efficient operations. Proficient in grain elevator maintenance, conveyor system troubleshooting, grain bin inspection and repair, grain spillage control, and safety protocol compliance. Committed to safety and working effectively in both individual and team environments.

Education

Associate’s or Bachelor’s Degree in Agriculture, Engineering

June 2017

Skills

- Chute Operation

- Grain Elevator Maintenance

- Conveyor System Troubleshooting

- Grain Bin Inspection and Repair

- Grain Spillage Control

- Safety Protocol Compliance

Work Experience

Chute Puller

- Assisted in the installation and maintenance of chute systems, gaining proficiency in various tools and equipment.

- Received training on safe work practices and hazard identification, demonstrating a commitment to safety.

- Worked effectively in both individual and team environments, fostering a positive and collaborative work culture.

- Utilized analytical skills to assess chute performance and identify areas for improvement.

Chute Puller

- Pulled chutes at a rate of 60 per hour, consistently achieving 100% accuracy.

- Collaborated with other team members to ensure smooth and efficient chute pulling operations.

- Identified and resolved chute malfunctions promptly, minimizing downtime.

- Maintained a clean and organized work area, adhering to safety protocols.

Accomplishments

- Successfully implemented a new chute design, resulting in a 15% increase in throughput and a 10% reduction in downtime.

- Developed and implemented a training program for new chute pullers, improving onboarding efficiency and reducing training time by 20%.

- Collaborated with engineers to design and implement a chute modification, increasing the capacity of the system by 12%.

- Successfully managed a team of chute pullers during a critical peak season, ensuring smooth operations and meeting production targets.

- Improved chute pulling techniques through ergonomic analysis, reducing physical strain and improving productivity by 7%.

Awards

- Chute Pulling Excellence Award Recognized for outstanding performance and efficiency in chute pulling operations, consistently exceeding quotas and safety standards.

- Chute Puller of the Year Awarded for exceptional proficiency and dedication, demonstrating superior knowledge and skills in chute pulling.

- Safety Excellence Award Recognized for consistently maintaining a safe and compliant work environment, ensuring the wellbeing of all team members.

- Chute Pulling Innovation Award Awarded for developing a new technique to enhance chute pulling efficiency, resulting in a 5% reduction in cycle time.

Certificates

- Grain Elevator Safety Certification

- Confined Space Entry Certification

- Forklift Operator Certification

- Grain Handling and Storage Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Chute Puller

- Highlight your experience and skills in chute pulling, grain elevator maintenance, and conveyor system troubleshooting.

- Quantify your accomplishments using specific metrics and data whenever possible.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Chute Puller Resume

- Efficiently pull chutes at a rate of 60 per hour, achieving 100% accuracy

- Resolve chute malfunctions promptly to minimize downtime

- Collaborate with team members to ensure smooth and efficient chute pulling operations

- Maintain a clean and organized work area, adhering to all safety protocols

- Assist in the installation and maintenance of chute systems, gaining proficiency in various tools and equipment

- Undertake training on safe work practices and hazard identification, displaying a strong commitment to safety

- Work effectively in both individual and team environments, fostering a positive and collaborative work culture

Frequently Asked Questions (FAQ’s) For Chute Puller

What is the primary responsibility of a Chute Puller?

The primary responsibility of a Chute Puller is to efficiently and accurately pull chutes at a specified rate, ensuring the smooth and efficient operation of grain elevators or similar facilities.

What skills are necessary for a Chute Puller?

Essential skills for a Chute Puller include experience in chute pulling, grain elevator maintenance, conveyor system troubleshooting, grain bin inspection and repair, and grain spillage control.

What is the work environment of a Chute Puller like?

Chute Pullers typically work in grain elevators or similar facilities, which can involve working in dusty and noisy environments for extended periods.

What are the career advancement opportunities for a Chute Puller?

With experience and additional training, Chute Pullers can advance to roles such as Grain Elevator Manager, Conveyor System Supervisor, or Safety Manager in the grain industry.

What are the safety protocols that a Chute Puller must follow?

Chute Pullers must adhere to strict safety protocols, including wearing appropriate personal protective equipment, following established procedures for chute pulling and maintenance, and being aware of potential hazards in the work environment.