Are you a seasoned Clamper seeking a new career path? Discover our professionally built Clamper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

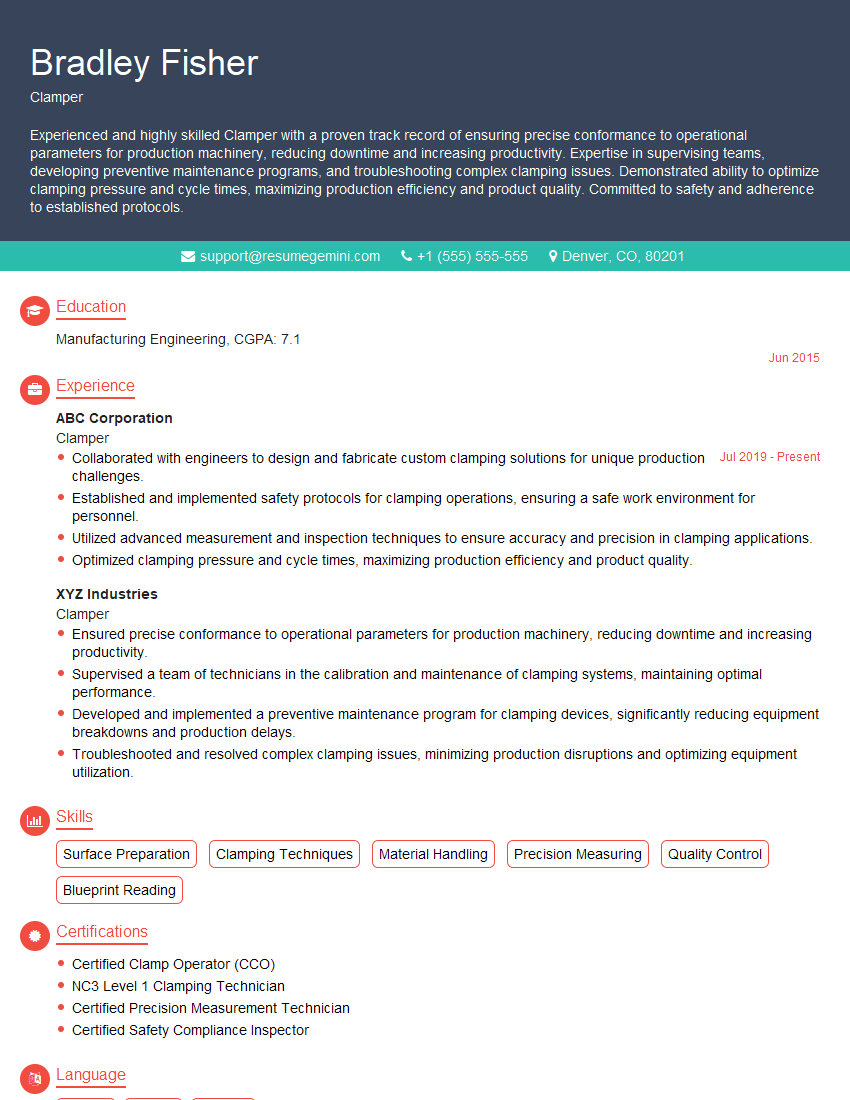

Bradley Fisher

Clamper

Summary

Experienced and highly skilled Clamper with a proven track record of ensuring precise conformance to operational parameters for production machinery, reducing downtime and increasing productivity. Expertise in supervising teams, developing preventive maintenance programs, and troubleshooting complex clamping issues. Demonstrated ability to optimize clamping pressure and cycle times, maximizing production efficiency and product quality. Committed to safety and adherence to established protocols.

Education

Manufacturing Engineering

June 2015

Skills

- Surface Preparation

- Clamping Techniques

- Material Handling

- Precision Measuring

- Quality Control

- Blueprint Reading

Work Experience

Clamper

- Collaborated with engineers to design and fabricate custom clamping solutions for unique production challenges.

- Established and implemented safety protocols for clamping operations, ensuring a safe work environment for personnel.

- Utilized advanced measurement and inspection techniques to ensure accuracy and precision in clamping applications.

- Optimized clamping pressure and cycle times, maximizing production efficiency and product quality.

Clamper

- Ensured precise conformance to operational parameters for production machinery, reducing downtime and increasing productivity.

- Supervised a team of technicians in the calibration and maintenance of clamping systems, maintaining optimal performance.

- Developed and implemented a preventive maintenance program for clamping devices, significantly reducing equipment breakdowns and production delays.

- Troubleshooted and resolved complex clamping issues, minimizing production disruptions and optimizing equipment utilization.

Certificates

- Certified Clamp Operator (CCO)

- NC3 Level 1 Clamping Technician

- Certified Precision Measurement Technician

- Certified Safety Compliance Inspector

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Clamper

- Highlight your experience in developing and implementing preventive maintenance programs.

- Quantify your accomplishments with specific metrics, such as reductions in downtime or improvements in production efficiency.

- Showcase your ability to work independently and as part of a team.

- Emphasize your commitment to safety and adherence to established protocols.

Essential Experience Highlights for a Strong Clamper Resume

- Supervised and trained a team of technicians in the calibration, maintenance, and repair of clamping systems.

- Developed and implemented a preventive maintenance program for clamping devices, significantly reducing equipment breakdowns and production delays.

- Collaborated with engineers to design, develop, and implement custom clamping solutions to meet unique production challenges.

- Optimized clamping pressure and cycle times, resulting in improved production efficiency and reduced product defects.

- Troubleshooted and resolved complex clamping issues, minimizing production disruptions and optimizing equipment utilization.

Frequently Asked Questions (FAQ’s) For Clamper

What is the primary role of a Clamper?

The primary role of a Clamper is to ensure precise conformance to operational parameters for production machinery, reducing downtime and increasing productivity.

What are the essential qualifications for a Clamper?

Essential qualifications typically include experience in supervising teams, developing preventive maintenance programs, troubleshooting complex clamping issues, and optimizing clamping pressure and cycle times.

What are the key responsibilities of a Clamper?

Key responsibilities often include supervising technicians, developing maintenance programs, collaborating with engineers, optimizing clamping systems, and troubleshooting complex issues.

What are the top skills required for a successful Clamper?

Top skills for Clampers include surface preparation, clamping techniques, material handling, precision measuring, quality control, blueprint reading, and a strong understanding of safety protocols.

What are the career advancement opportunities for a Clamper?

With experience and additional training, Clampers can advance to roles such as Production Supervisor, Manufacturing Engineer, or Quality Control Manager.

What is the average salary range for a Clamper?

According to industry estimates, the average salary range for Clampers in the United States is between $40,000 and $65,000 per year.

What are the essential safety precautions that Clampers must follow?

Clampers must adhere to established safety protocols, including wearing appropriate personal protective equipment, following lockout/tagout procedures, and maintaining a clean and organized work area.