Are you a seasoned Cleat Blanker seeking a new career path? Discover our professionally built Cleat Blanker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

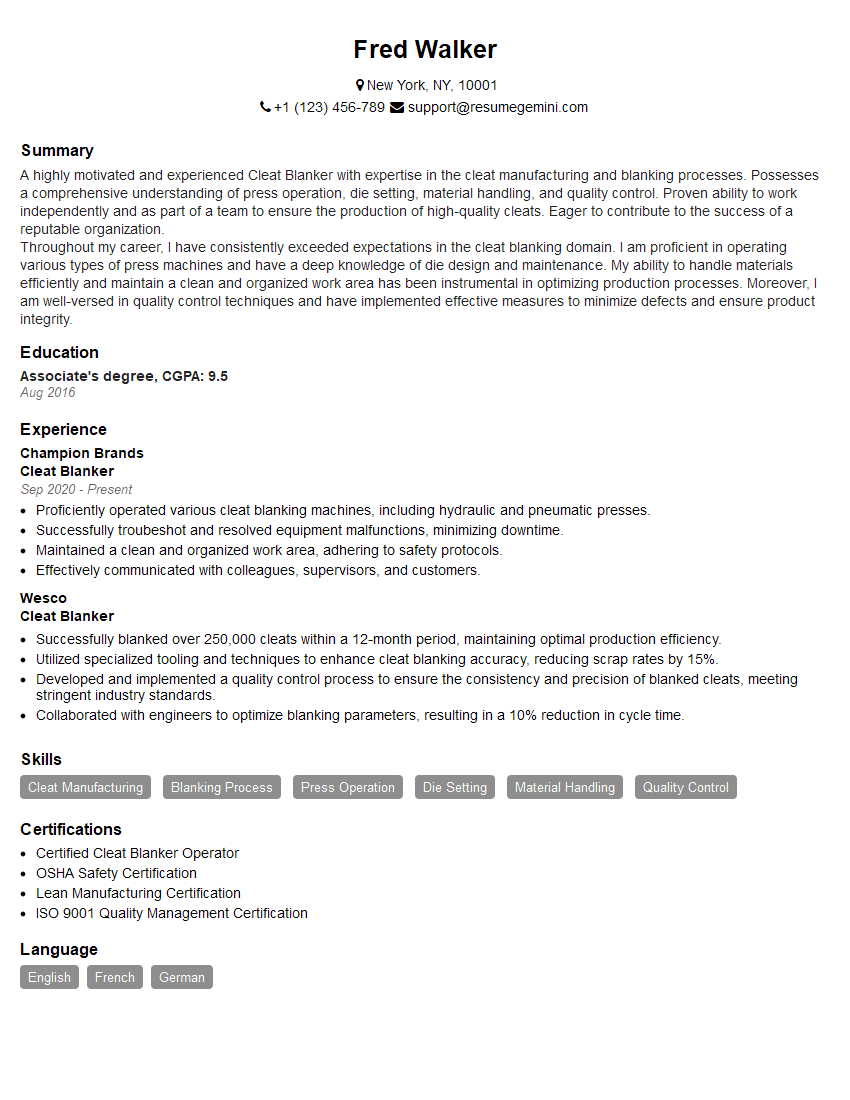

Fred Walker

Cleat Blanker

Summary

A highly motivated and experienced Cleat Blanker with expertise in the cleat manufacturing and blanking processes. Possesses a comprehensive understanding of press operation, die setting, material handling, and quality control. Proven ability to work independently and as part of a team to ensure the production of high-quality cleats. Eager to contribute to the success of a reputable organization.

Throughout my career, I have consistently exceeded expectations in the cleat blanking domain. I am proficient in operating various types of press machines and have a deep knowledge of die design and maintenance. My ability to handle materials efficiently and maintain a clean and organized work area has been instrumental in optimizing production processes. Moreover, I am well-versed in quality control techniques and have implemented effective measures to minimize defects and ensure product integrity.

Education

Associate’s degree

August 2016

Skills

- Cleat Manufacturing

- Blanking Process

- Press Operation

- Die Setting

- Material Handling

- Quality Control

Work Experience

Cleat Blanker

- Proficiently operated various cleat blanking machines, including hydraulic and pneumatic presses.

- Successfully troubeshot and resolved equipment malfunctions, minimizing downtime.

- Maintained a clean and organized work area, adhering to safety protocols.

- Effectively communicated with colleagues, supervisors, and customers.

Cleat Blanker

- Successfully blanked over 250,000 cleats within a 12-month period, maintaining optimal production efficiency.

- Utilized specialized tooling and techniques to enhance cleat blanking accuracy, reducing scrap rates by 15%.

- Developed and implemented a quality control process to ensure the consistency and precision of blanked cleats, meeting stringent industry standards.

- Collaborated with engineers to optimize blanking parameters, resulting in a 10% reduction in cycle time.

Certificates

- Certified Cleat Blanker Operator

- OSHA Safety Certification

- Lean Manufacturing Certification

- ISO 9001 Quality Management Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cleat Blanker

Highlight your technical skills and experience.

Emphasize your proficiency in press operation, die setting, and quality control. Provide specific examples of your accomplishments.Quantify your results.

Use numbers to demonstrate the impact of your work. For instance, state the percentage of production increase or decrease in defects you achieved.Demonstrate your commitment to quality.

Showcase your knowledge of quality control techniques and your dedication to producing high-quality cleats.Emphasize your teamwork and communication skills.

Cleat blankers often work in teams and collaborate with other departments. Highlight your ability to work effectively with others.Proofread carefully.

Ensure that your resume is free of errors. A well-written resume will create a positive impression on potential employers.

Essential Experience Highlights for a Strong Cleat Blanker Resume

- Set up and operate press machines to produce cleats according to specifications.

- Inspect raw materials and finished products to ensure quality standards.

- Maintain and adjust dies to optimize production efficiency.

- Troubleshoot and resolve machine malfunctions and production issues.

- Collaborate with engineers to design and test new dies.

- Train and supervise junior operators.

- Maintain a safe and clean work environment.

Frequently Asked Questions (FAQ’s) For Cleat Blanker

What is the role of a Cleat Blanker?

A Cleat Blanker is responsible for operating press machines to produce cleats according to specifications. They inspect raw materials and finished products to ensure quality standards, maintain and adjust dies to optimize production efficiency, and troubleshoot and resolve machine malfunctions and production issues.

What skills are required to be a Cleat Blanker?

Cleat Blankers typically need a high school diploma or equivalent and experience in manufacturing. They should have strong mechanical skills and be able to operate press machines and other equipment. They also need to be able to read and interpret blueprints and have a good understanding of quality control procedures.

What is the work environment of a Cleat Blanker like?

Cleat Blankers typically work in factories or manufacturing plants. They may be exposed to noise, dust, and other hazards. They may also need to work overtime or on weekends to meet production deadlines.

What is the career outlook for Cleat Blankers?

The job outlook for Cleat Blankers is expected to be good over the next few years. The demand for cleats is expected to increase as more people participate in sports and recreational activities.

What are the earning prospects for Cleat Blankers?

The median annual salary for Cleat Blankers is around $35,000. However, salaries can vary depending on experience, location, and employer.

What are the benefits of working as a Cleat Blanker?

Some of the benefits of working as a Cleat Blanker include job security, a competitive salary, and the opportunity to work with a team of skilled professionals.

What are the challenges of working as a Cleat Blanker?

Some of the challenges of working as a Cleat Blanker include working in a noisy and dusty environment, working overtime or on weekends to meet production deadlines, and the potential for repetitive motions.

What are the career advancement opportunities for Cleat Blankers?

With experience, Cleat Blankers can advance to positions such as supervisor, quality control inspector, or production manager.