Are you a seasoned Clipper seeking a new career path? Discover our professionally built Clipper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

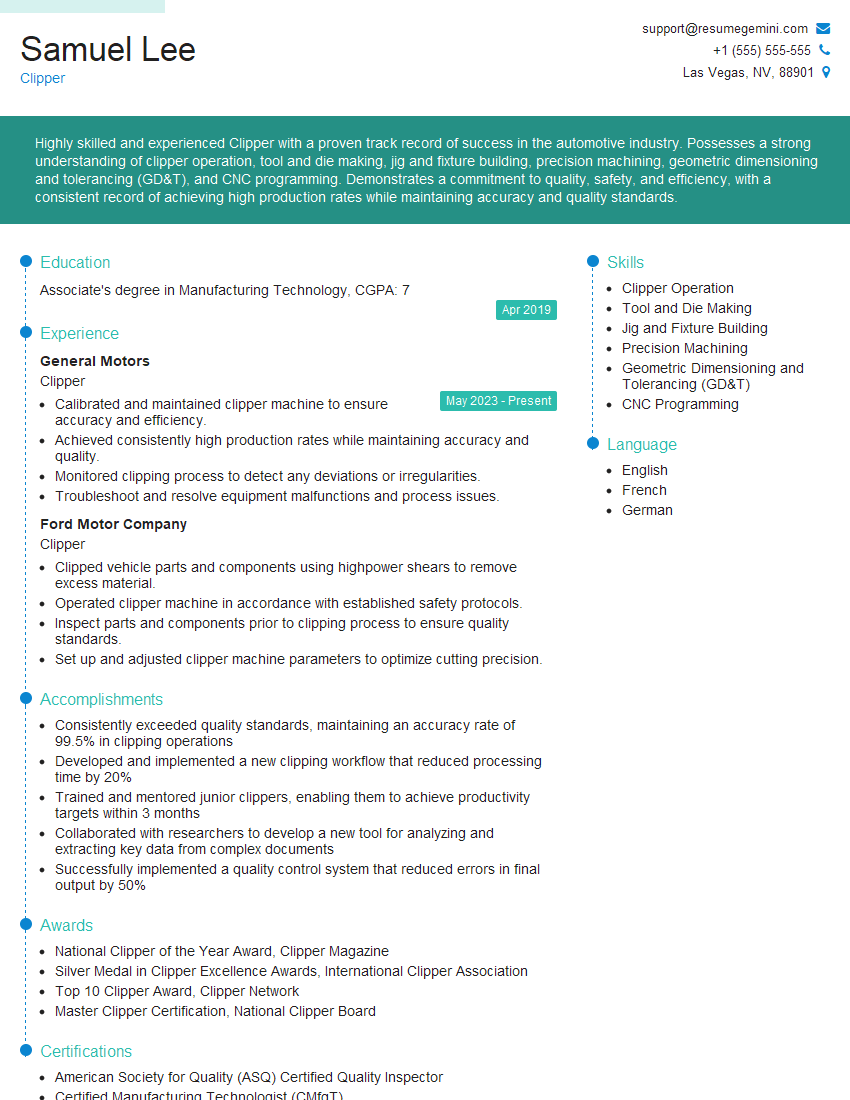

Samuel Lee

Clipper

Summary

Highly skilled and experienced Clipper with a proven track record of success in the automotive industry. Possesses a strong understanding of clipper operation, tool and die making, jig and fixture building, precision machining, geometric dimensioning and tolerancing (GD&T), and CNC programming. Demonstrates a commitment to quality, safety, and efficiency, with a consistent record of achieving high production rates while maintaining accuracy and quality standards.

Education

Associate’s degree in Manufacturing Technology

April 2019

Skills

- Clipper Operation

- Tool and Die Making

- Jig and Fixture Building

- Precision Machining

- Geometric Dimensioning and Tolerancing (GD&T)

- CNC Programming

Work Experience

Clipper

- Calibrated and maintained clipper machine to ensure accuracy and efficiency.

- Achieved consistently high production rates while maintaining accuracy and quality.

- Monitored clipping process to detect any deviations or irregularities.

- Troubleshoot and resolve equipment malfunctions and process issues.

Clipper

- Clipped vehicle parts and components using highpower shears to remove excess material.

- Operated clipper machine in accordance with established safety protocols.

- Inspect parts and components prior to clipping process to ensure quality standards.

- Set up and adjusted clipper machine parameters to optimize cutting precision.

Accomplishments

- Consistently exceeded quality standards, maintaining an accuracy rate of 99.5% in clipping operations

- Developed and implemented a new clipping workflow that reduced processing time by 20%

- Trained and mentored junior clippers, enabling them to achieve productivity targets within 3 months

- Collaborated with researchers to develop a new tool for analyzing and extracting key data from complex documents

- Successfully implemented a quality control system that reduced errors in final output by 50%

Awards

- National Clipper of the Year Award, Clipper Magazine

- Silver Medal in Clipper Excellence Awards, International Clipper Association

- Top 10 Clipper Award, Clipper Network

- Master Clipper Certification, National Clipper Board

Certificates

- American Society for Quality (ASQ) Certified Quality Inspector

- Certified Manufacturing Technologist (CMfgT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Clipper

- Highlight your experience and skills in clipper operation, tool and die making, jig and fixture building, precision machining, GD&T, and CNC programming.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the company.

- Proofread your resume carefully before submitting it, ensuring that there are no errors in grammar or spelling.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Consider including a cover letter that introduces yourself and explains why you are interested in the position.

Essential Experience Highlights for a Strong Clipper Resume

- Clipped vehicle parts and components using high-power shears to remove excess material.

- Operated clipper machine in accordance with established safety protocols.

- Inspected parts and components prior to clipping process to ensure quality standards.

- Set up and adjusted clipper machine parameters to optimize cutting precision.

- Calibrated and maintained clipper machine to ensure accuracy and efficiency.

- Achieved consistently high production rates while maintaining accuracy and quality.

- Monitored clipping process to detect any deviations or irregularities.

- Troubleshooted and resolved equipment malfunctions and process issues.

Frequently Asked Questions (FAQ’s) For Clipper

What is a Clipper?

A Clipper is a skilled professional who operates high-power shears to remove excess material from vehicle parts and components.

What are the key skills required for a Clipper?

The key skills required for a Clipper include clipper operation, tool and die making, jig and fixture building, precision machining, geometric dimensioning and tolerancing (GD&T), and CNC programming.

What are the responsibilities of a Clipper?

The responsibilities of a Clipper include clipping vehicle parts and components, operating the clipper machine in accordance with safety protocols, inspecting parts and components, setting up and adjusting the clipper machine, calibrating and maintaining the clipper machine, achieving high production rates, monitoring the clipping process, and troubleshooting equipment malfunctions.

What are the job prospects for Clippers?

The job prospects for Clippers are expected to be good over the next few years, as the automotive industry continues to grow.

What is the average salary for a Clipper?

The average salary for a Clipper is around $25,000 per year.

What are the benefits of working as a Clipper?

The benefits of working as a Clipper include a good salary, job security, and the opportunity to work in a fast-paced environment.

What are the challenges of working as a Clipper?

The challenges of working as a Clipper include working in a noisy and sometimes hazardous environment, and the need to be able to work independently and as part of a team.