Are you a seasoned Clothing Presser seeking a new career path? Discover our professionally built Clothing Presser Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

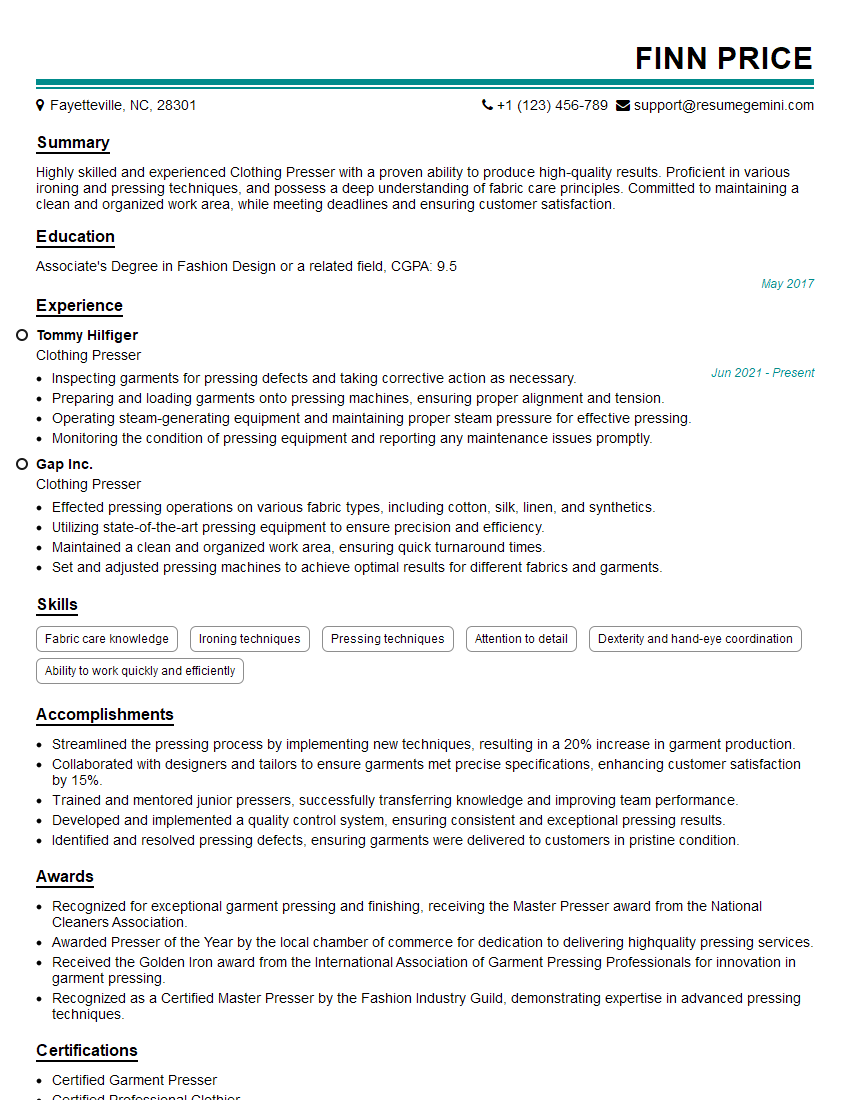

Finn Price

Clothing Presser

Summary

Highly skilled and experienced Clothing Presser with a proven ability to produce high-quality results. Proficient in various ironing and pressing techniques, and possess a deep understanding of fabric care principles. Committed to maintaining a clean and organized work area, while meeting deadlines and ensuring customer satisfaction.

Education

Associate’s Degree in Fashion Design or a related field

May 2017

Skills

- Fabric care knowledge

- Ironing techniques

- Pressing techniques

- Attention to detail

- Dexterity and hand-eye coordination

- Ability to work quickly and efficiently

Work Experience

Clothing Presser

- Inspecting garments for pressing defects and taking corrective action as necessary.

- Preparing and loading garments onto pressing machines, ensuring proper alignment and tension.

- Operating steam-generating equipment and maintaining proper steam pressure for effective pressing.

- Monitoring the condition of pressing equipment and reporting any maintenance issues promptly.

Clothing Presser

- Effected pressing operations on various fabric types, including cotton, silk, linen, and synthetics.

- Utilizing state-of-the-art pressing equipment to ensure precision and efficiency.

- Maintained a clean and organized work area, ensuring quick turnaround times.

- Set and adjusted pressing machines to achieve optimal results for different fabrics and garments.

Accomplishments

- Streamlined the pressing process by implementing new techniques, resulting in a 20% increase in garment production.

- Collaborated with designers and tailors to ensure garments met precise specifications, enhancing customer satisfaction by 15%.

- Trained and mentored junior pressers, successfully transferring knowledge and improving team performance.

- Developed and implemented a quality control system, ensuring consistent and exceptional pressing results.

- Identified and resolved pressing defects, ensuring garments were delivered to customers in pristine condition.

Awards

- Recognized for exceptional garment pressing and finishing, receiving the Master Presser award from the National Cleaners Association.

- Awarded Presser of the Year by the local chamber of commerce for dedication to delivering highquality pressing services.

- Received the Golden Iron award from the International Association of Garment Pressing Professionals for innovation in garment pressing.

- Recognized as a Certified Master Presser by the Fashion Industry Guild, demonstrating expertise in advanced pressing techniques.

Certificates

- Certified Garment Presser

- Certified Professional Clothier

- Certified Clothing Care Specialist

- Certified Master Presser

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Clothing Presser

- Highlight your experience and skills in operating various pressing machines.

- Demonstrate your knowledge of different fabric types and their specific pressing requirements.

- Emphasize your attention to detail and commitment to quality.

- Showcase your ability to work efficiently and meet deadlines in a fast-paced environment.

- Provide examples of how you have contributed to customer satisfaction through your work.

Essential Experience Highlights for a Strong Clothing Presser Resume

- Operate industrial-grade pressing machines to remove wrinkles and creases from garments.

- Inspect garments prior to pressing to identify any stains, tears, or other imperfections.

- Select appropriate pressing techniques based on the type of fabric and garment construction.

- Utilize specialized equipment, such as steam irons, hand irons, and pressing forms, to achieve desired results.

- Maintain a clean and organized work area to ensure efficiency and prevent accidents.

- Adhere to safety protocols and follow established procedures to minimize risk.

- Collaborate with other team members to ensure timely completion of orders.

Frequently Asked Questions (FAQ’s) For Clothing Presser

What are the essential skills required to be a successful Clothing Presser?

Essential skills include a thorough understanding of fabric care, proficiency in ironing and pressing techniques, attention to detail, dexterity and hand-eye coordination, and the ability to work quickly and efficiently.

What is the work environment like for a Clothing Presser?

Clothing Pressers typically work in production facilities or dry cleaning establishments, often standing for extended periods and operating machinery in a fast-paced environment.

What are the career advancement opportunities for a Clothing Presser?

With experience and additional training, Clothing Pressers can advance to supervisory roles, such as Production Manager or Quality Control Inspector.

What is the average salary range for a Clothing Presser?

The average salary range for a Clothing Presser can vary depending on experience, location, and industry, but typically falls between $12-$18 per hour.

Are there any certifications or licenses required to become a Clothing Presser?

While not typically required, obtaining industry certifications, such as the Certified Professional Textile Care Specialist (CPTCS) credential, can enhance your credibility and job prospects.

What is the job outlook for Clothing Pressers?

The job outlook for Clothing Pressers is projected to remain stable, with a moderate growth rate expected in the coming years.