Are you a seasoned CNC Machine Operator (Computer Numerically Controlled Machine Operator) seeking a new career path? Discover our professionally built CNC Machine Operator (Computer Numerically Controlled Machine Operator) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

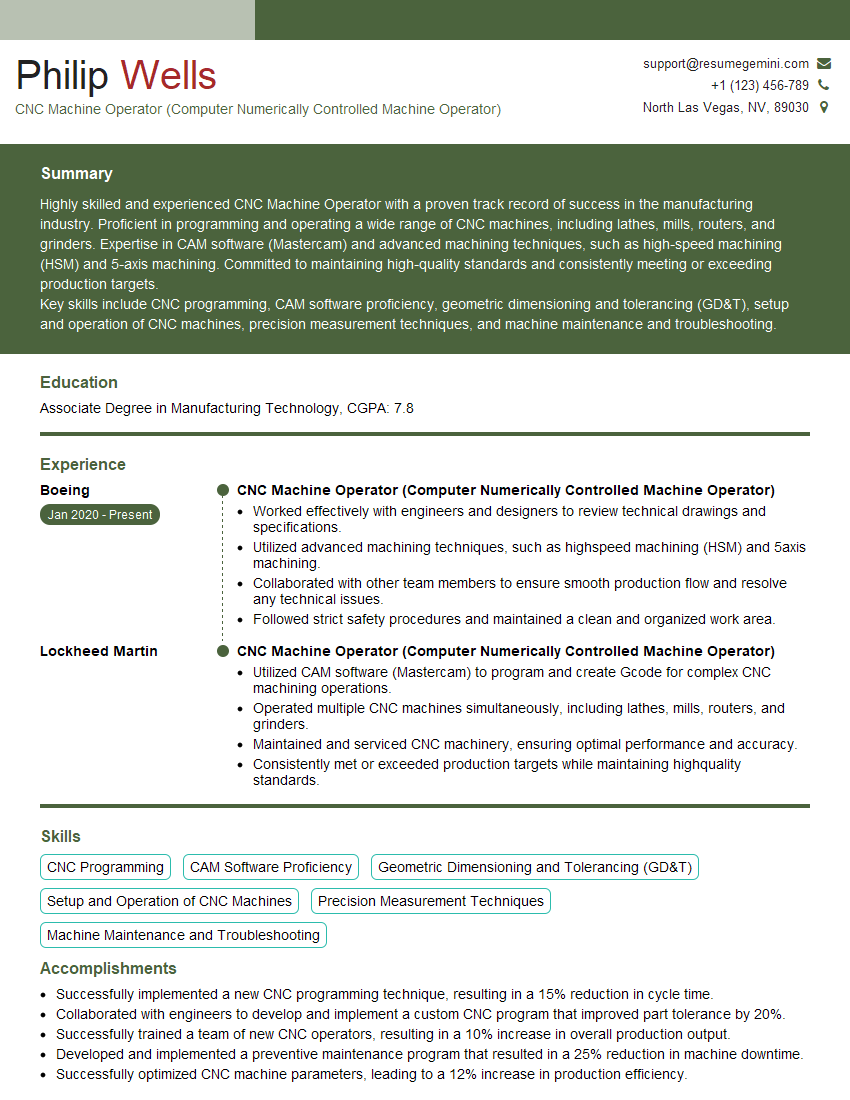

Philip Wells

CNC Machine Operator (Computer Numerically Controlled Machine Operator)

Summary

Highly skilled and experienced CNC Machine Operator with a proven track record of success in the manufacturing industry. Proficient in programming and operating a wide range of CNC machines, including lathes, mills, routers, and grinders. Expertise in CAM software (Mastercam) and advanced machining techniques, such as high-speed machining (HSM) and 5-axis machining. Committed to maintaining high-quality standards and consistently meeting or exceeding production targets.

Key skills include CNC programming, CAM software proficiency, geometric dimensioning and tolerancing (GD&T), setup and operation of CNC machines, precision measurement techniques, and machine maintenance and troubleshooting.

Education

Associate Degree in Manufacturing Technology

December 2015

Skills

- CNC Programming

- CAM Software Proficiency

- Geometric Dimensioning and Tolerancing (GD&T)

- Setup and Operation of CNC Machines

- Precision Measurement Techniques

- Machine Maintenance and Troubleshooting

Work Experience

CNC Machine Operator (Computer Numerically Controlled Machine Operator)

- Worked effectively with engineers and designers to review technical drawings and specifications.

- Utilized advanced machining techniques, such as highspeed machining (HSM) and 5axis machining.

- Collaborated with other team members to ensure smooth production flow and resolve any technical issues.

- Followed strict safety procedures and maintained a clean and organized work area.

CNC Machine Operator (Computer Numerically Controlled Machine Operator)

- Utilized CAM software (Mastercam) to program and create Gcode for complex CNC machining operations.

- Operated multiple CNC machines simultaneously, including lathes, mills, routers, and grinders.

- Maintained and serviced CNC machinery, ensuring optimal performance and accuracy.

- Consistently met or exceeded production targets while maintaining highquality standards.

Accomplishments

- Successfully implemented a new CNC programming technique, resulting in a 15% reduction in cycle time.

- Collaborated with engineers to develop and implement a custom CNC program that improved part tolerance by 20%.

- Successfully trained a team of new CNC operators, resulting in a 10% increase in overall production output.

- Developed and implemented a preventive maintenance program that resulted in a 25% reduction in machine downtime.

- Successfully optimized CNC machine parameters, leading to a 12% increase in production efficiency.

Awards

- Recipient of the CNC Operator of the Year Award for achieving exceptional productivity and precision.

- Recognized for maintaining a perfect quality record for over 5,000 CNC parts produced.

- Awarded the Safety Excellence Award for adhering to all safety protocols and implementing innovative safety measures.

- Recognized for exceptional problemsolving skills in troubleshooting and resolving complex CNC issues.

Certificates

- CNC Operator Certification

- CAM Programming Certification

- GD&T Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For CNC Machine Operator (Computer Numerically Controlled Machine Operator)

- Highlight your skills and experience in CNC programming and CAM software.

- Showcase your knowledge of advanced machining techniques, such as HSM and 5-axis machining.

- Quantify your accomplishments and provide specific examples of how you have contributed to production goals.

- Demonstrate your commitment to safety and maintaining a clean work environment.

Essential Experience Highlights for a Strong CNC Machine Operator (Computer Numerically Controlled Machine Operator) Resume

- Program and operate CNC machines to create complex parts and components.

- Interpret technical drawings and specifications to determine machining parameters.

- Set up and maintain CNC machinery, ensuring optimal performance and accuracy.

- Troubleshoot and resolve technical issues to minimize downtime.

- Collaborate with engineers and designers to review designs and provide feedback.

- Maintain a clean and organized work area, adhering to strict safety procedures.

- Continuously improve processes and identify opportunities for optimization.

Frequently Asked Questions (FAQ’s) For CNC Machine Operator (Computer Numerically Controlled Machine Operator)

What is the role of a CNC Machine Operator?

A CNC Machine Operator is responsible for programming, setting up, and operating computer numerically controlled (CNC) machines to create complex parts and components. They interpret technical drawings and specifications, determine machining parameters, and ensure that the machines are operating at optimal performance and accuracy.

What skills are required to be a successful CNC Machine Operator?

Successful CNC Machine Operators possess strong skills in CNC programming, CAM software proficiency, geometric dimensioning and tolerancing (GD&T), setup and operation of CNC machines, precision measurement techniques, and machine maintenance and troubleshooting. They are also proficient in reading and interpreting technical drawings and specifications.

What are the career prospects for CNC Machine Operators?

CNC Machine Operators are in high demand due to the increasing use of CNC machines in various industries. They have the opportunity to advance their careers by specializing in specific areas, such as advanced machining techniques or CAM software development.

What is the work environment of a CNC Machine Operator?

CNC Machine Operators typically work in manufacturing facilities or machine shops. They operate CNC machines in a controlled environment, ensuring that the machines are operating safely and efficiently.

What are the safety precautions that CNC Machine Operators must follow?

CNC Machine Operators must adhere to strict safety procedures to minimize the risk of accidents and injuries. They wear appropriate safety gear, follow lockout/tagout procedures, and maintain a clean and organized work area.

How can I become a CNC Machine Operator?

To become a CNC Machine Operator, you can complete an associate degree or certificate program in manufacturing technology or a related field. You can also gain experience through apprenticeships or on-the-job training.