Are you a seasoned CNC Machinist (Computer Numerically Controlled Machinist) seeking a new career path? Discover our professionally built CNC Machinist (Computer Numerically Controlled Machinist) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

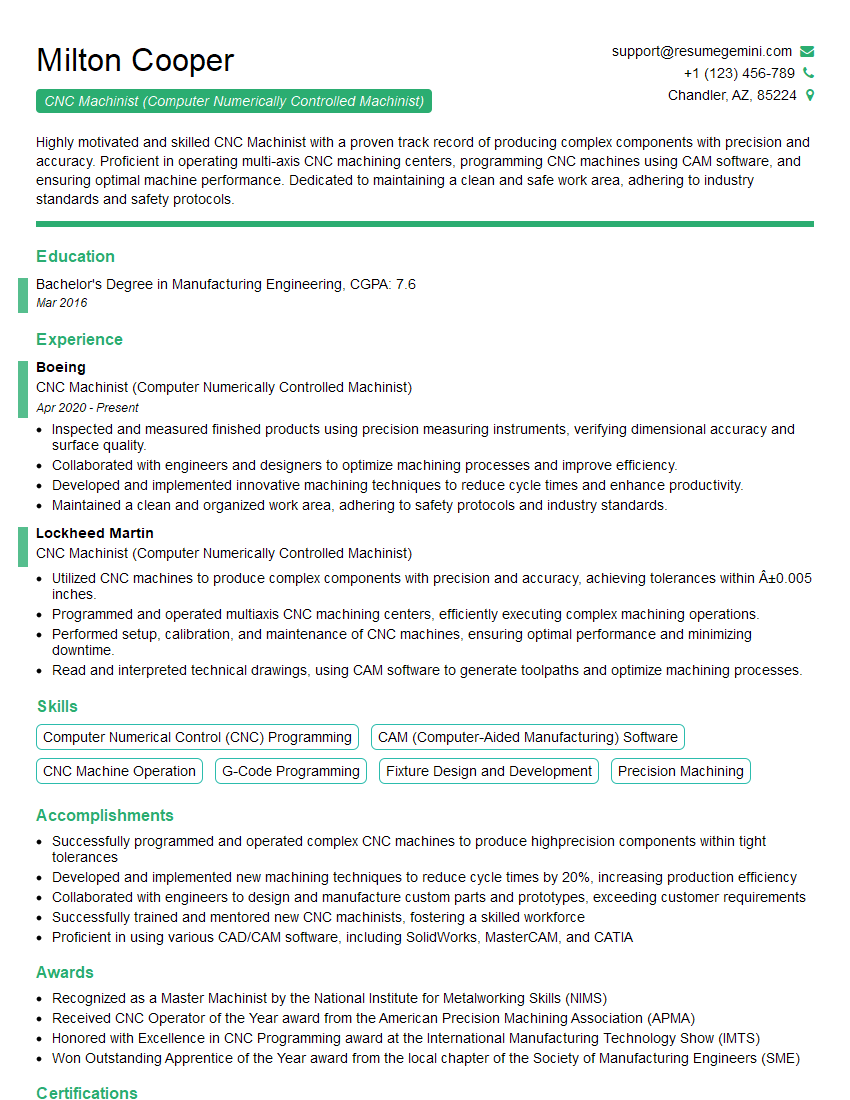

Milton Cooper

CNC Machinist (Computer Numerically Controlled Machinist)

Summary

Highly motivated and skilled CNC Machinist with a proven track record of producing complex components with precision and accuracy. Proficient in operating multi-axis CNC machining centers, programming CNC machines using CAM software, and ensuring optimal machine performance. Dedicated to maintaining a clean and safe work area, adhering to industry standards and safety protocols.

Education

Bachelor’s Degree in Manufacturing Engineering

March 2016

Skills

- Computer Numerical Control (CNC) Programming

- CAM (Computer-Aided Manufacturing) Software

- CNC Machine Operation

- G-Code Programming

- Fixture Design and Development

- Precision Machining

Work Experience

CNC Machinist (Computer Numerically Controlled Machinist)

- Inspected and measured finished products using precision measuring instruments, verifying dimensional accuracy and surface quality.

- Collaborated with engineers and designers to optimize machining processes and improve efficiency.

- Developed and implemented innovative machining techniques to reduce cycle times and enhance productivity.

- Maintained a clean and organized work area, adhering to safety protocols and industry standards.

CNC Machinist (Computer Numerically Controlled Machinist)

- Utilized CNC machines to produce complex components with precision and accuracy, achieving tolerances within ±0.005 inches.

- Programmed and operated multiaxis CNC machining centers, efficiently executing complex machining operations.

- Performed setup, calibration, and maintenance of CNC machines, ensuring optimal performance and minimizing downtime.

- Read and interpreted technical drawings, using CAM software to generate toolpaths and optimize machining processes.

Accomplishments

- Successfully programmed and operated complex CNC machines to produce highprecision components within tight tolerances

- Developed and implemented new machining techniques to reduce cycle times by 20%, increasing production efficiency

- Collaborated with engineers to design and manufacture custom parts and prototypes, exceeding customer requirements

- Successfully trained and mentored new CNC machinists, fostering a skilled workforce

- Proficient in using various CAD/CAM software, including SolidWorks, MasterCAM, and CATIA

Awards

- Recognized as a Master Machinist by the National Institute for Metalworking Skills (NIMS)

- Received CNC Operator of the Year award from the American Precision Machining Association (APMA)

- Honored with Excellence in CNC Programming award at the International Manufacturing Technology Show (IMTS)

- Won Outstanding Apprentice of the Year award from the local chapter of the Society of Manufacturing Engineers (SME)

Certificates

- CNC Machinist Certification (NIMS/CMMC)

- MasterCAM Certification

- SolidWorks Certification

- GD&T Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For CNC Machinist (Computer Numerically Controlled Machinist)

- Highlight your CNC programming skills and experience in using CAM software.

- Showcase your knowledge of CNC machine operation, setup, calibration, and maintenance.

- Emphasize your ability to work independently and as part of a team.

- Include quantifiable results that demonstrate your impact on productivity and efficiency.

Essential Experience Highlights for a Strong CNC Machinist (Computer Numerically Controlled Machinist) Resume

- Programmed and operated multi-axis CNC machining centers to produce complex components within tight tolerances (±0.005 inches).

- Utilized CAM software to generate toolpaths, optimize machining processes, and reduce cycle times.

- Performed setup, calibration, and maintenance of CNC machines to ensure optimal performance and minimize downtime.

- Inspected and measured finished products using precision measuring instruments to verify dimensional accuracy and surface quality.

- Collaborated with engineers and designers to optimize machining processes and improve efficiency.

- Developed and implemented innovative machining techniques to enhance productivity.

Frequently Asked Questions (FAQ’s) For CNC Machinist (Computer Numerically Controlled Machinist)

What is the role of a CNC Machinist?

A CNC Machinist is responsible for programming, operating, and maintaining CNC machines to produce complex components with precision and accuracy.

What skills are required to be a CNC Machinist?

CNC Machinists should have proficiency in CNC programming, CAM software, CNC machine operation, G-Code programming, fixture design and development, and precision machining.

What industries employ CNC Machinists?

CNC Machinists are employed in various industries, including aerospace, automotive, manufacturing, and medical device manufacturing.

What is the job outlook for CNC Machinists?

The job outlook for CNC Machinists is expected to be positive due to the increasing demand for precision manufacturing.

What is the earning potential for CNC Machinists?

The earning potential for CNC Machinists varies depending on experience, skills, and location, but generally ranges from $25,000 to $75,000 per year.

What are the career advancement opportunities for CNC Machinists?

CNC Machinists can advance their careers by becoming CNC programmers, supervisors, or managers.

What training and certification are available for CNC Machinists?

CNC Machinists can obtain training and certification from vocational schools, community colleges, and industry organizations.

What is the work environment for CNC Machinists?

CNC Machinists typically work in clean and well-lit workshops or manufacturing facilities, using CNC machines and precision measuring instruments.