Are you a seasoned CNC Mill Operator (Computerized Numerical Control Mill Operator) seeking a new career path? Discover our professionally built CNC Mill Operator (Computerized Numerical Control Mill Operator) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

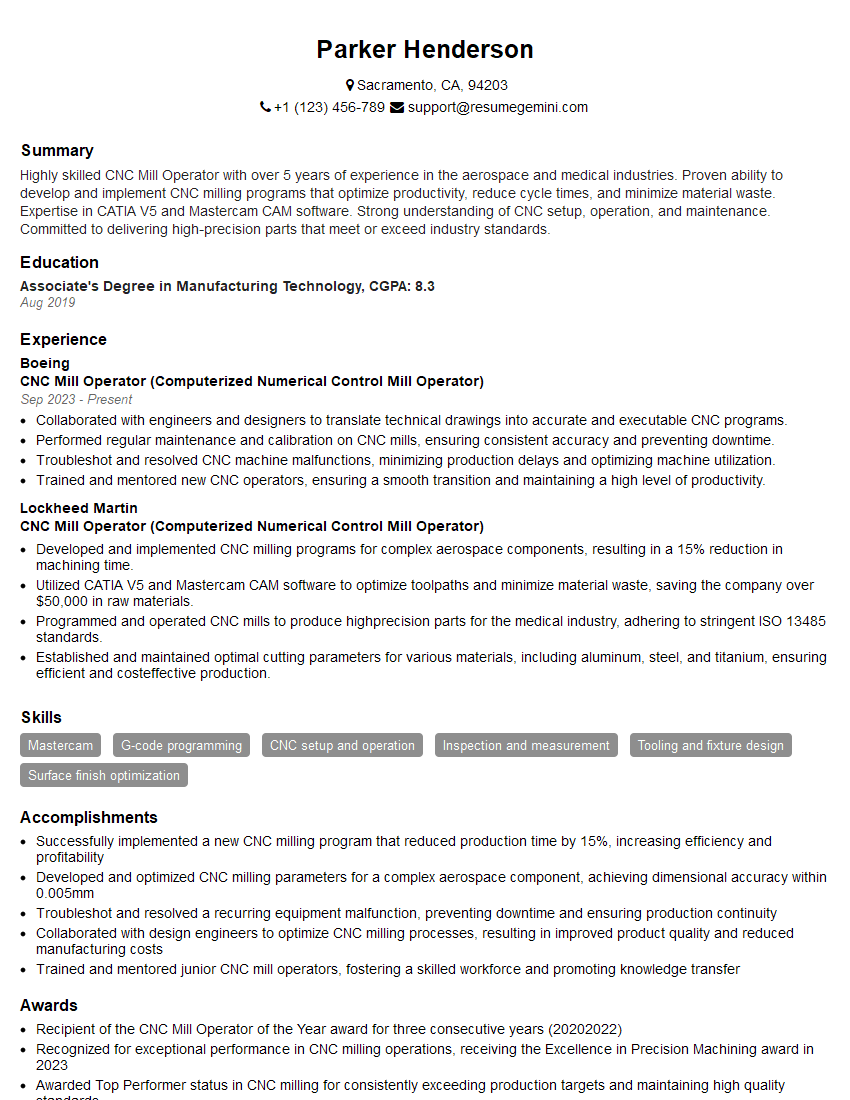

Parker Henderson

CNC Mill Operator (Computerized Numerical Control Mill Operator)

Summary

Highly skilled CNC Mill Operator with over 5 years of experience in the aerospace and medical industries. Proven ability to develop and implement CNC milling programs that optimize productivity, reduce cycle times, and minimize material waste. Expertise in CATIA V5 and Mastercam CAM software. Strong understanding of CNC setup, operation, and maintenance. Committed to delivering high-precision parts that meet or exceed industry standards.

Education

Associate’s Degree in Manufacturing Technology

August 2019

Skills

- Mastercam

- G-code programming

- CNC setup and operation

- Inspection and measurement

- Tooling and fixture design

- Surface finish optimization

Work Experience

CNC Mill Operator (Computerized Numerical Control Mill Operator)

- Collaborated with engineers and designers to translate technical drawings into accurate and executable CNC programs.

- Performed regular maintenance and calibration on CNC mills, ensuring consistent accuracy and preventing downtime.

- Troubleshot and resolved CNC machine malfunctions, minimizing production delays and optimizing machine utilization.

- Trained and mentored new CNC operators, ensuring a smooth transition and maintaining a high level of productivity.

CNC Mill Operator (Computerized Numerical Control Mill Operator)

- Developed and implemented CNC milling programs for complex aerospace components, resulting in a 15% reduction in machining time.

- Utilized CATIA V5 and Mastercam CAM software to optimize toolpaths and minimize material waste, saving the company over $50,000 in raw materials.

- Programmed and operated CNC mills to produce highprecision parts for the medical industry, adhering to stringent ISO 13485 standards.

- Established and maintained optimal cutting parameters for various materials, including aluminum, steel, and titanium, ensuring efficient and costeffective production.

Accomplishments

- Successfully implemented a new CNC milling program that reduced production time by 15%, increasing efficiency and profitability

- Developed and optimized CNC milling parameters for a complex aerospace component, achieving dimensional accuracy within 0.005mm

- Troubleshot and resolved a recurring equipment malfunction, preventing downtime and ensuring production continuity

- Collaborated with design engineers to optimize CNC milling processes, resulting in improved product quality and reduced manufacturing costs

- Trained and mentored junior CNC mill operators, fostering a skilled workforce and promoting knowledge transfer

Awards

- Recipient of the CNC Mill Operator of the Year award for three consecutive years (20202022)

- Recognized for exceptional performance in CNC milling operations, receiving the Excellence in Precision Machining award in 2023

- Awarded Top Performer status in CNC milling for consistently exceeding production targets and maintaining high quality standards

- Selected for a prestigious training program on advanced CNC milling techniques, demonstrating commitment to professional development

Certificates

- Certified Manufacturing Technologist (CMfgT)

- National Institute for Metalworking Skills (NIMS) credentials

- CNC Programming certification from a recognized institution

- ISO 9001:2015 Quality Management Systems certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For CNC Mill Operator (Computerized Numerical Control Mill Operator)

- Highlight your experience in operating and programming CNC mills, particularly in aerospace or medical applications.

- Showcase your proficiency in CAM software, such as Mastercam or CATIA V5, and your ability to optimize toolpaths for efficiency.

- Emphasize your commitment to quality and your understanding of ISO standards, especially ISO 13485 for medical devices.

- Demonstrate your problem-solving skills by describing how you have resolved CNC machine malfunctions and ensured optimal performance.

- Consider obtaining certifications in CNC operation or CAM software to enhance your credibility.

Essential Experience Highlights for a Strong CNC Mill Operator (Computerized Numerical Control Mill Operator) Resume

- Develop and implement CNC milling programs for complex components, ensuring optimal machining efficiency and accuracy.

- Utilize CAM software to optimize toolpaths and minimize material waste, resulting in significant cost savings.

- Program and operate CNC mills to produce high-precision parts for aerospace and medical applications, adhering to stringent quality standards.

- Establish and maintain optimal cutting parameters for various materials, maximizing productivity and tool life.

- Collaborate with engineers and designers to translate technical drawings into accurate and executable CNC programs.

- Perform regular maintenance and calibration on CNC mills, ensuring consistent accuracy and preventing downtime.

- Troubleshoot and resolve CNC machine malfunctions, minimizing production delays and optimizing machine utilization.

Frequently Asked Questions (FAQ’s) For CNC Mill Operator (Computerized Numerical Control Mill Operator)

What are the key skills required for a CNC Mill Operator?

Essential skills include proficiency in CNC programming and operation, knowledge of CAM software, understanding of cutting parameters, experience with inspection and measurement techniques, and familiarity with tooling and fixture design.

What are the career prospects for CNC Mill Operators?

CNC Mill Operators are in high demand due to the growing use of CNC technology in various industries. Experienced operators can advance to supervisory roles, become CAM programmers, or specialize in specific areas such as aerospace or medical manufacturing.

What is the work environment of a CNC Mill Operator like?

CNC Mill Operators typically work in manufacturing facilities or machine shops. The work environment can be noisy and requires attention to detail and safety procedures. They often work with other machinists, engineers, and quality control personnel.

What are the educational requirements for becoming a CNC Mill Operator?

While a high school diploma is typically sufficient, many employers prefer candidates with an Associate’s Degree in Manufacturing Technology or a related field. Additionally, CNC training programs and certifications can enhance your skills and job prospects.

How can I prepare for an interview as a CNC Mill Operator?

Research the company and the specific industry they operate in. Practice answering common interview questions related to CNC operation, programming, and troubleshooting. Highlight your relevant skills and experience, and be prepared to discuss your ability to work independently and as part of a team.

What is the average salary for a CNC Mill Operator?

The salary range for CNC Mill Operators can vary depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for CNC Machine Tool Operators was around $48,000 in May 2022.

What are the safety precautions that CNC Mill Operators should follow?

CNC Mill Operators must adhere to strict safety protocols to minimize risks. These include wearing appropriate personal protective equipment (PPE), following lockout/tagout procedures, being aware of moving machinery, and maintaining a clean and organized work area.

How can CNC Mill Operators stay updated with the latest industry trends?

Attending industry events, reading trade publications, and pursuing continuing education opportunities can help CNC Mill Operators stay informed about technological advancements, best practices, and industry regulations.