Are you a seasoned CNC Programmer (Computerized Numerical Control Programmer) seeking a new career path? Discover our professionally built CNC Programmer (Computerized Numerical Control Programmer) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

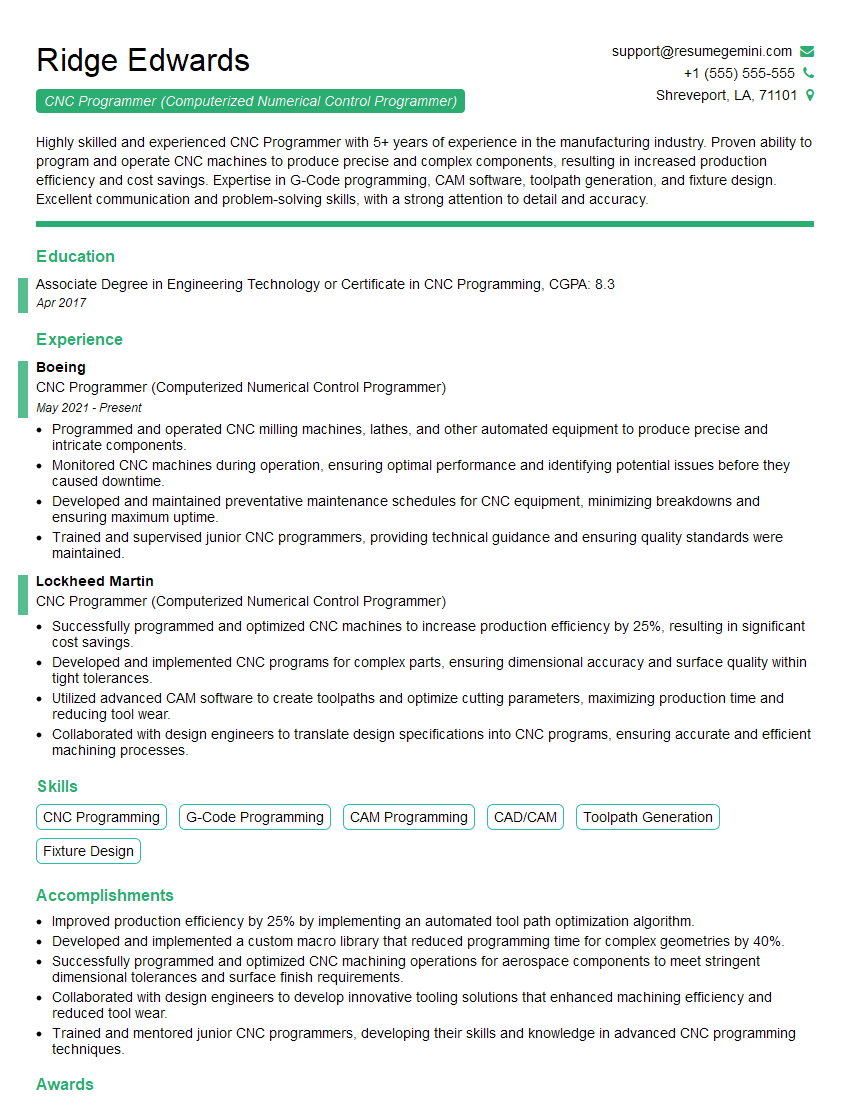

Ridge Edwards

CNC Programmer (Computerized Numerical Control Programmer)

Summary

Highly skilled and experienced CNC Programmer with 5+ years of experience in the manufacturing industry. Proven ability to program and operate CNC machines to produce precise and complex components, resulting in increased production efficiency and cost savings. Expertise in G-Code programming, CAM software, toolpath generation, and fixture design. Excellent communication and problem-solving skills, with a strong attention to detail and accuracy.

Education

Associate Degree in Engineering Technology or Certificate in CNC Programming

April 2017

Skills

- CNC Programming

- G-Code Programming

- CAM Programming

- CAD/CAM

- Toolpath Generation

- Fixture Design

Work Experience

CNC Programmer (Computerized Numerical Control Programmer)

- Programmed and operated CNC milling machines, lathes, and other automated equipment to produce precise and intricate components.

- Monitored CNC machines during operation, ensuring optimal performance and identifying potential issues before they caused downtime.

- Developed and maintained preventative maintenance schedules for CNC equipment, minimizing breakdowns and ensuring maximum uptime.

- Trained and supervised junior CNC programmers, providing technical guidance and ensuring quality standards were maintained.

CNC Programmer (Computerized Numerical Control Programmer)

- Successfully programmed and optimized CNC machines to increase production efficiency by 25%, resulting in significant cost savings.

- Developed and implemented CNC programs for complex parts, ensuring dimensional accuracy and surface quality within tight tolerances.

- Utilized advanced CAM software to create toolpaths and optimize cutting parameters, maximizing production time and reducing tool wear.

- Collaborated with design engineers to translate design specifications into CNC programs, ensuring accurate and efficient machining processes.

Accomplishments

- Improved production efficiency by 25% by implementing an automated tool path optimization algorithm.

- Developed and implemented a custom macro library that reduced programming time for complex geometries by 40%.

- Successfully programmed and optimized CNC machining operations for aerospace components to meet stringent dimensional tolerances and surface finish requirements.

- Collaborated with design engineers to develop innovative tooling solutions that enhanced machining efficiency and reduced tool wear.

- Trained and mentored junior CNC programmers, developing their skills and knowledge in advanced CNC programming techniques.

Awards

- Received the prestigious CNC Programmer of the Year award at the International CNC Programming Conference.

- Won the Excellence in CNC Programming award at the regional CNC Programmer Association competition.

- Recognized as a Top 10% CNC Programmer by the National Association of CNC Programmers.

- Received the Golden Chip Award for outstanding contributions to the CNC programming industry.

Certificates

- Certified CNC Programmer

- Mastercam Certified User

- SolidWorks Certified Associate

- ISO 9001 Lead Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For CNC Programmer (Computerized Numerical Control Programmer)

- Highlight your skills and experience in CNC programming, G-Code programming, CAM programming, and CAD/CAM.

- Quantify your accomplishments with specific metrics, such as increasing production efficiency by a certain percentage or reducing costs by a certain amount.

- Showcase your ability to work independently and as part of a team, and your willingness to learn new technologies.

- Tailor your resume to each job you apply for by highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong CNC Programmer (Computerized Numerical Control Programmer) Resume

- Program and optimize CNC machines using G-Code and CAM software to increase production efficiency and reduce costs.

- Develop and implement CNC programs for complex parts, ensuring dimensional accuracy and surface quality within tight tolerances.

- Collaborate with design engineers to translate design specifications into CNC programs, ensuring accurate and efficient machining processes.

- Program and operate CNC milling machines, lathes, and other automated equipment to produce precise and intricate components.

- Monitor CNC machines during operation, ensuring optimal performance and identifying potential issues before they cause downtime.

- Develop and maintain preventative maintenance schedules for CNC equipment, minimizing breakdowns and ensuring maximum uptime.

- Train and supervise junior CNC programmers, providing technical guidance and ensuring quality standards are maintained.

Frequently Asked Questions (FAQ’s) For CNC Programmer (Computerized Numerical Control Programmer)

What is the role of a CNC Programmer?

A CNC Programmer is responsible for creating and optimizing CNC programs that control the movement of CNC machines. They use specialized software to generate toolpaths and cutting parameters, ensuring that parts are produced to the required specifications.

What are the key skills for a CNC Programmer?

Key skills for a CNC Programmer include CNC programming, G-Code programming, CAM programming, CAD/CAM, toolpath generation, and fixture design.

What is the job market for CNC Programmers?

The job market for CNC Programmers is expected to grow in the coming years due to the increasing demand for automated manufacturing processes.

What is the salary range for CNC Programmers?

The salary range for CNC Programmers varies depending on experience, skills, and location. According to Indeed, the average salary for a CNC Programmer in the United States is around $60,000 per year.

What are the career prospects for CNC Programmers?

CNC Programmers can advance their careers by becoming CNC Machinists, CNC Supervisors, or CNC Manufacturing Engineers.

What are the challenges of working as a CNC Programmer?

Challenges of working as a CNC Programmer include working with complex machinery, interpreting engineering drawings, and staying up-to-date with the latest technologies.

What is the future of CNC Programming?

The future of CNC Programming is expected to be driven by advancements in automation, artificial intelligence, and cloud computing.