Are you a seasoned CNC Technician (Computer Numerical Control Technician) seeking a new career path? Discover our professionally built CNC Technician (Computer Numerical Control Technician) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

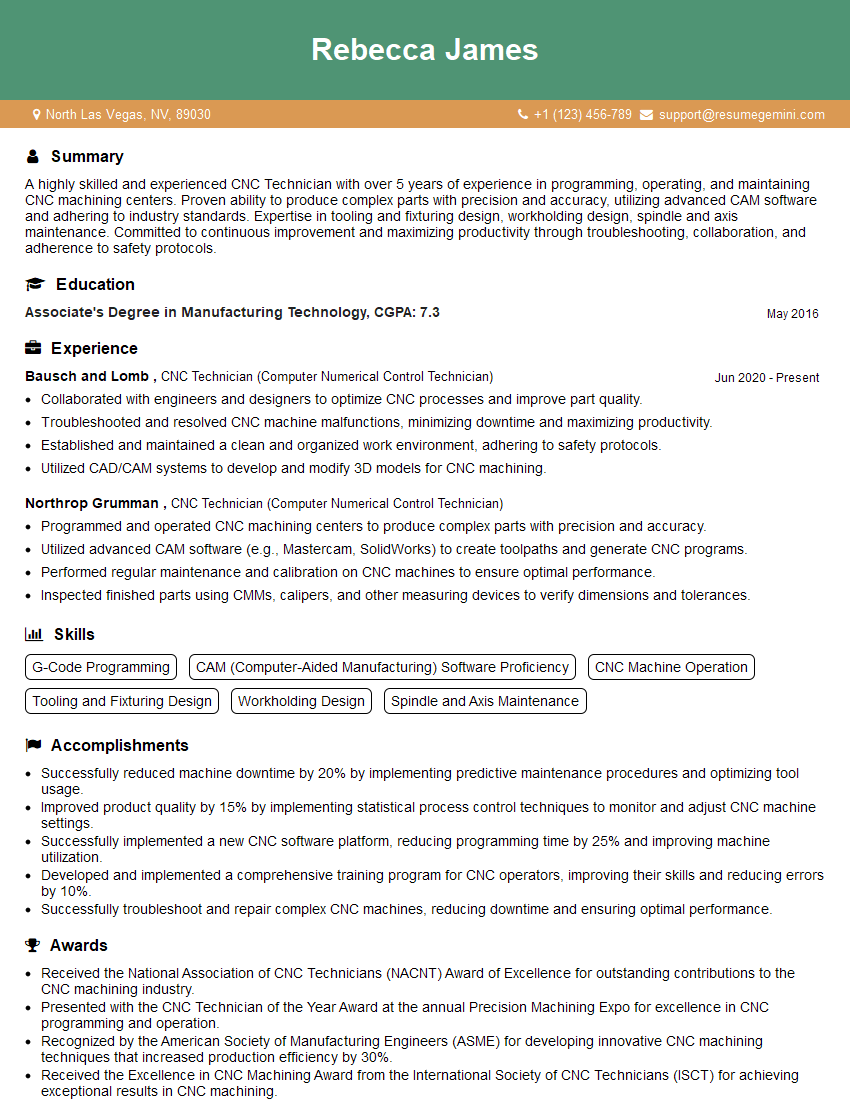

Rebecca James

CNC Technician (Computer Numerical Control Technician)

Summary

A highly skilled and experienced CNC Technician with over 5 years of experience in programming, operating, and maintaining CNC machining centers. Proven ability to produce complex parts with precision and accuracy, utilizing advanced CAM software and adhering to industry standards. Expertise in tooling and fixturing design, workholding design, spindle and axis maintenance. Committed to continuous improvement and maximizing productivity through troubleshooting, collaboration, and adherence to safety protocols.

Education

Associate’s Degree in Manufacturing Technology

May 2016

Skills

- G-Code Programming

- CAM (Computer-Aided Manufacturing) Software Proficiency

- CNC Machine Operation

- Tooling and Fixturing Design

- Workholding Design

- Spindle and Axis Maintenance

Work Experience

CNC Technician (Computer Numerical Control Technician)

- Collaborated with engineers and designers to optimize CNC processes and improve part quality.

- Troubleshooted and resolved CNC machine malfunctions, minimizing downtime and maximizing productivity.

- Established and maintained a clean and organized work environment, adhering to safety protocols.

- Utilized CAD/CAM systems to develop and modify 3D models for CNC machining.

CNC Technician (Computer Numerical Control Technician)

- Programmed and operated CNC machining centers to produce complex parts with precision and accuracy.

- Utilized advanced CAM software (e.g., Mastercam, SolidWorks) to create toolpaths and generate CNC programs.

- Performed regular maintenance and calibration on CNC machines to ensure optimal performance.

- Inspected finished parts using CMMs, calipers, and other measuring devices to verify dimensions and tolerances.

Accomplishments

- Successfully reduced machine downtime by 20% by implementing predictive maintenance procedures and optimizing tool usage.

- Improved product quality by 15% by implementing statistical process control techniques to monitor and adjust CNC machine settings.

- Successfully implemented a new CNC software platform, reducing programming time by 25% and improving machine utilization.

- Developed and implemented a comprehensive training program for CNC operators, improving their skills and reducing errors by 10%.

- Successfully troubleshoot and repair complex CNC machines, reducing downtime and ensuring optimal performance.

Awards

- Received the National Association of CNC Technicians (NACNT) Award of Excellence for outstanding contributions to the CNC machining industry.

- Presented with the CNC Technician of the Year Award at the annual Precision Machining Expo for excellence in CNC programming and operation.

- Recognized by the American Society of Manufacturing Engineers (ASME) for developing innovative CNC machining techniques that increased production efficiency by 30%.

- Received the Excellence in CNC Machining Award from the International Society of CNC Technicians (ISCT) for achieving exceptional results in CNC machining.

Certificates

- Certified CNC Programmer (MCP)

- Certified CNC Technician (CCT)

- Certified Manufacturing Technologist (CMfgT)

- Six Sigma Black Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For CNC Technician (Computer Numerical Control Technician)

- Highlight your skills in G-Code programming, CAM software proficiency, CNC machine operation, and tooling and fixturing design.

- Showcase your experience in troubleshooting and resolving CNC machine malfunctions, emphasizing your ability to minimize downtime and maximize productivity.

- Include quantifiable results whenever possible, such as the number of parts produced, the accuracy achieved, or the cost savings generated.

- Tailor your resume to each job you apply for, highlighting the skills and experience most relevant to the specific position.

Essential Experience Highlights for a Strong CNC Technician (Computer Numerical Control Technician) Resume

- Program and operate CNC machining centers to produce complex parts with precision and accuracy.

- Utilize advanced CAM software (e.g., Mastercam, SolidWorks) to create toolpaths and generate CNC programs.

- Perform regular maintenance and calibration on CNC machines to ensure optimal performance.

- Inspect finished parts using CMMs, calipers, and other measuring devices to verify dimensions and tolerances.

- Collaborate with engineers and designers to optimize CNC processes and improve part quality.

- Troubleshoot and resolve CNC machine malfunctions, minimizing downtime and maximizing productivity.

- Establish and maintain a clean and organized work environment, adhering to safety protocols.

Frequently Asked Questions (FAQ’s) For CNC Technician (Computer Numerical Control Technician)

What are the primary responsibilities of a CNC Technician?

The primary responsibilities of a CNC Technician include programming and operating CNC machining centers, utilizing CAM software to create toolpaths and generate CNC programs, performing regular maintenance and calibration on CNC machines, inspecting finished parts to verify dimensions and tolerances, and collaborating with engineers and designers to optimize CNC processes and improve part quality.

What skills are required to be a successful CNC Technician?

Successful CNC Technicians typically possess strong skills in G-Code programming, CAM software proficiency, CNC machine operation, tooling and fixturing design, workholding design, spindle and axis maintenance, and troubleshooting.

What are the career opportunities for CNC Technicians?

CNC Technicians can find employment in various industries, including manufacturing, aerospace, automotive, and medical device manufacturing. They may work in roles such as CNC Programmer, CNC Operator, CNC Maintenance Technician, or CNC Supervisor.

What is the job outlook for CNC Technicians?

The job outlook for CNC Technicians is expected to remain positive due to the increasing demand for skilled workers in the manufacturing industry. The use of CNC machines is becoming more widespread, and companies are seeking qualified technicians to operate and maintain these machines.

What are the educational requirements for CNC Technicians?

Many CNC Technicians have an Associate’s Degree in Manufacturing Technology or a related field. However, some employers may hire candidates with a high school diploma or equivalent and provide on-the-job training.

What certifications are available for CNC Technicians?

CNC Technicians can obtain certifications from organizations such as the National Institute for Metalworking Skills (NIMS) and the Society of Manufacturing Engineers (SME).

How can I prepare for a career as a CNC Technician?

To prepare for a career as a CNC Technician, you can pursue an education in manufacturing technology, take CNC programming courses, and gain hands-on experience through internships or apprenticeships.