Are you a seasoned Coater Operator seeking a new career path? Discover our professionally built Coater Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

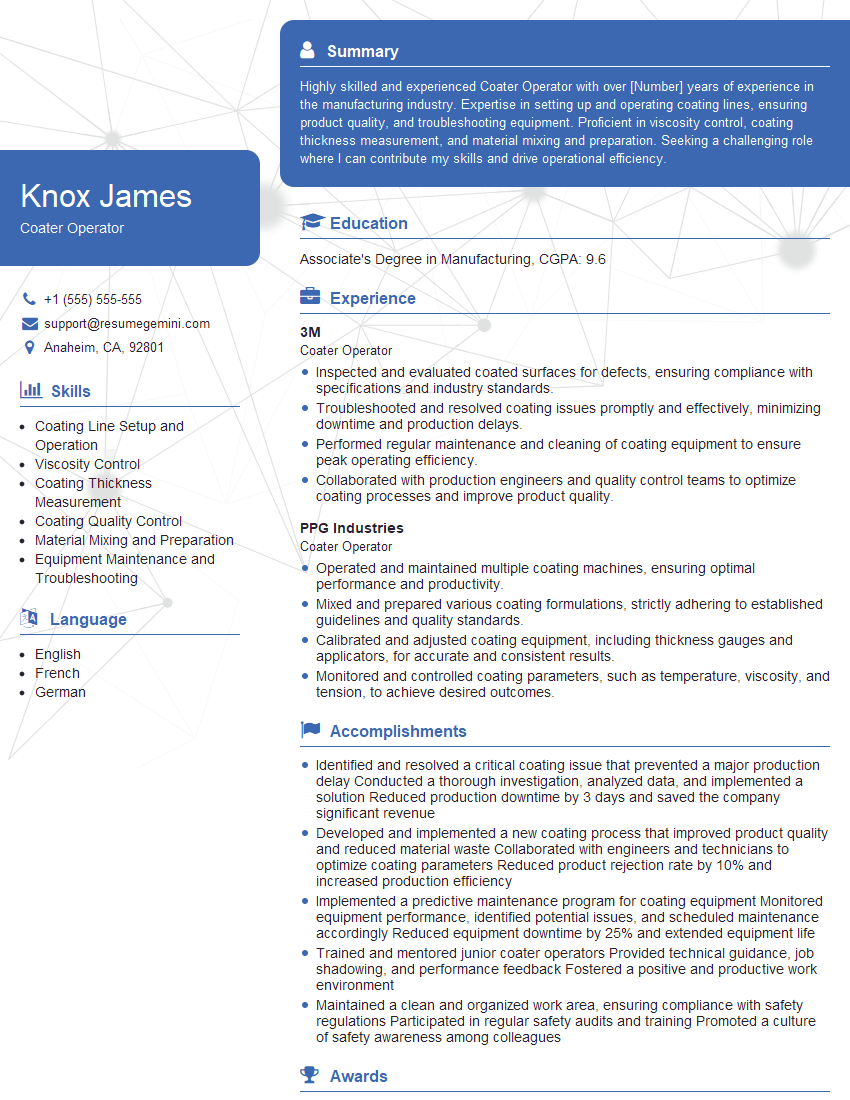

Knox James

Coater Operator

Summary

Highly skilled and experienced Coater Operator with over [Number] years of experience in the manufacturing industry. Expertise in setting up and operating coating lines, ensuring product quality, and troubleshooting equipment. Proficient in viscosity control, coating thickness measurement, and material mixing and preparation. Seeking a challenging role where I can contribute my skills and drive operational efficiency.

Education

Associate’s Degree in Manufacturing

April 2018

Skills

- Coating Line Setup and Operation

- Viscosity Control

- Coating Thickness Measurement

- Coating Quality Control

- Material Mixing and Preparation

- Equipment Maintenance and Troubleshooting

Work Experience

Coater Operator

- Inspected and evaluated coated surfaces for defects, ensuring compliance with specifications and industry standards.

- Troubleshooted and resolved coating issues promptly and effectively, minimizing downtime and production delays.

- Performed regular maintenance and cleaning of coating equipment to ensure peak operating efficiency.

- Collaborated with production engineers and quality control teams to optimize coating processes and improve product quality.

Coater Operator

- Operated and maintained multiple coating machines, ensuring optimal performance and productivity.

- Mixed and prepared various coating formulations, strictly adhering to established guidelines and quality standards.

- Calibrated and adjusted coating equipment, including thickness gauges and applicators, for accurate and consistent results.

- Monitored and controlled coating parameters, such as temperature, viscosity, and tension, to achieve desired outcomes.

Accomplishments

- Identified and resolved a critical coating issue that prevented a major production delay Conducted a thorough investigation, analyzed data, and implemented a solution Reduced production downtime by 3 days and saved the company significant revenue

- Developed and implemented a new coating process that improved product quality and reduced material waste Collaborated with engineers and technicians to optimize coating parameters Reduced product rejection rate by 10% and increased production efficiency

- Implemented a predictive maintenance program for coating equipment Monitored equipment performance, identified potential issues, and scheduled maintenance accordingly Reduced equipment downtime by 25% and extended equipment life

- Trained and mentored junior coater operators Provided technical guidance, job shadowing, and performance feedback Fostered a positive and productive work environment

- Maintained a clean and organized work area, ensuring compliance with safety regulations Participated in regular safety audits and training Promoted a culture of safety awareness among colleagues

Awards

- Received the Coater Operator of the Year award for exceptional performance and commitment to quality

- Recognized for achieving outstanding production efficiency, exceeding targets by 15%

- Awarded for implementing innovative techniques that reduced coating defects by 20%

Certificates

- Coating Operator Certification (e.g., SSPC, NACE, APSP)

- ISO 9001 Lead Auditor Certification

- Six Sigma Green Belt or Black Belt Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coater Operator

- Highlight your experience in operating and maintaining coating lines specifically.

- Showcase your understanding of viscosity control and coating thickness measurement techniques.

- Mention any certifications or training you have in coating operations.

- Emphasize your ability to work independently and as part of a team.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Coater Operator Resume

- Set up and operate coating lines according to established procedures.

- Control viscosity and coating thickness to meet product specifications.

- Conduct quality control tests to ensure coated products meet industry standards.

- Mix and prepare materials used in the coating process.

- Maintain and troubleshoot coating equipment to minimize downtime.

- Monitor production processes and make adjustments as needed to optimize efficiency.

- Follow safety protocols and maintain a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Coater Operator

What are the key skills required to be a successful Coater Operator?

Key skills include coating line setup and operation, viscosity control, coating thickness measurement, coating quality control, material mixing and preparation, equipment maintenance and troubleshooting.

What industries employ Coater Operators?

Coater Operators are employed in various industries, including manufacturing, automotive, aerospace, and electronics.

What is the average salary for a Coater Operator?

The average salary for a Coater Operator varies depending on experience, location, and industry, but typically ranges between $30,000 to $50,000 per year.

What are the career advancement opportunities for Coater Operators?

Coater Operators can advance to roles such as Production Supervisor, Quality Control Inspector, or Coating Line Manager.

What is the job outlook for Coater Operators?

The job outlook for Coater Operators is expected to be good over the next decade due to the growing demand for coated products in various industries.

What is the work environment like for Coater Operators?

Coater Operators typically work in manufacturing facilities and may be exposed to hazardous chemicals and noise.

What are the benefits of being a Coater Operator?

Benefits may include health insurance, paid time off, and retirement plans.

What are the challenges of being a Coater Operator?

Challenges may include working in a fast-paced environment and meeting production targets.