Are you a seasoned Coke Oven Patcher seeking a new career path? Discover our professionally built Coke Oven Patcher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

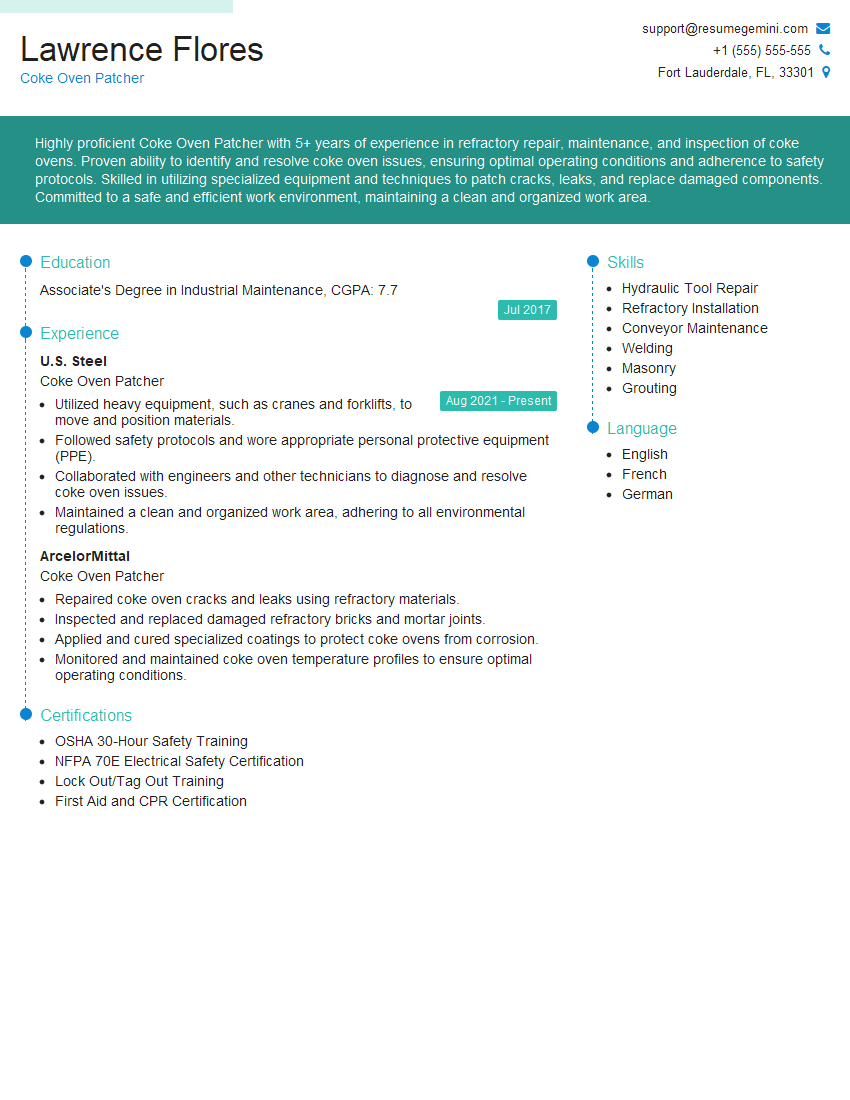

Lawrence Flores

Coke Oven Patcher

Summary

Highly proficient Coke Oven Patcher with 5+ years of experience in refractory repair, maintenance, and inspection of coke ovens. Proven ability to identify and resolve coke oven issues, ensuring optimal operating conditions and adherence to safety protocols. Skilled in utilizing specialized equipment and techniques to patch cracks, leaks, and replace damaged components. Committed to a safe and efficient work environment, maintaining a clean and organized work area.

Education

Associate’s Degree in Industrial Maintenance

July 2017

Skills

- Hydraulic Tool Repair

- Refractory Installation

- Conveyor Maintenance

- Welding

- Masonry

- Grouting

Work Experience

Coke Oven Patcher

- Utilized heavy equipment, such as cranes and forklifts, to move and position materials.

- Followed safety protocols and wore appropriate personal protective equipment (PPE).

- Collaborated with engineers and other technicians to diagnose and resolve coke oven issues.

- Maintained a clean and organized work area, adhering to all environmental regulations.

Coke Oven Patcher

- Repaired coke oven cracks and leaks using refractory materials.

- Inspected and replaced damaged refractory bricks and mortar joints.

- Applied and cured specialized coatings to protect coke ovens from corrosion.

- Monitored and maintained coke oven temperature profiles to ensure optimal operating conditions.

Certificates

- OSHA 30-Hour Safety Training

- NFPA 70E Electrical Safety Certification

- Lock Out/Tag Out Training

- First Aid and CPR Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coke Oven Patcher

- Highlight your expertise in refractory repair and maintenance techniques.

- Emphasize your ability to work independently and as part of a team in a fast-paced environment.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your knowledge of coke oven operations and safety protocols.

Essential Experience Highlights for a Strong Coke Oven Patcher Resume

- Repaired coke oven cracks and leaks using refractory materials and specialized coatings.

- Inspected and replaced damaged refractory bricks and mortar joints to maintain structural integrity.

- Monitored and maintained coke oven temperature profiles to ensure optimal operating conditions.

- Utilized heavy equipment, such as cranes and forklifts, to move and position materials.

- Collaborated with engineers and other technicians to diagnose and resolve coke oven issues.

- Followed safety protocols and wore appropriate personal protective equipment (PPE) to ensure a safe work environment.

Frequently Asked Questions (FAQ’s) For Coke Oven Patcher

What are the primary duties of a Coke Oven Patcher?

Coke Oven Patchers are responsible for maintaining and repairing coke ovens, including patching cracks and leaks, replacing damaged components, and monitoring oven temperatures. They also ensure that safety protocols are followed and that the work area is clean and organized.

What qualifications are required to become a Coke Oven Patcher?

Typically, Coke Oven Patchers have an Associate’s Degree in Industrial Maintenance or a related field, along with 2-3 years of experience in refractory repair and maintenance.

What are the key skills needed for success as a Coke Oven Patcher?

Coke Oven Patchers should possess strong knowledge of refractory repair techniques, welding, masonry, and grouting. They should also be able to operate heavy equipment and work independently and as part of a team.

What is the work environment like for a Coke Oven Patcher?

Coke Oven Patchers typically work in hot and dusty conditions, often in confined spaces. They must be able to work safely and efficiently in these environments, while adhering to strict safety protocols.

What are the career advancement opportunities for a Coke Oven Patcher?

With experience and additional training, Coke Oven Patchers can advance to positions such as Refractory Supervisor or Maintenance Manager. They may also specialize in specific areas, such as welding or automation.

What are the safety hazards associated with being a Coke Oven Patcher?

Coke Oven Patchers work with hazardous materials and equipment, so they must be aware of potential hazards such as burns, falls, and exposure to toxic fumes. They must follow all safety protocols and wear appropriate personal protective equipment (PPE) to minimize risks.

What are the key trends and technologies impacting the Coke Oven Patcher profession?

The Coke Oven Patcher profession is constantly evolving, with new technologies and techniques being developed to improve safety and efficiency. Automation, remote monitoring, and advanced materials are some of the key trends shaping the future of the profession.