Are you a seasoned Cold Header Operator seeking a new career path? Discover our professionally built Cold Header Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

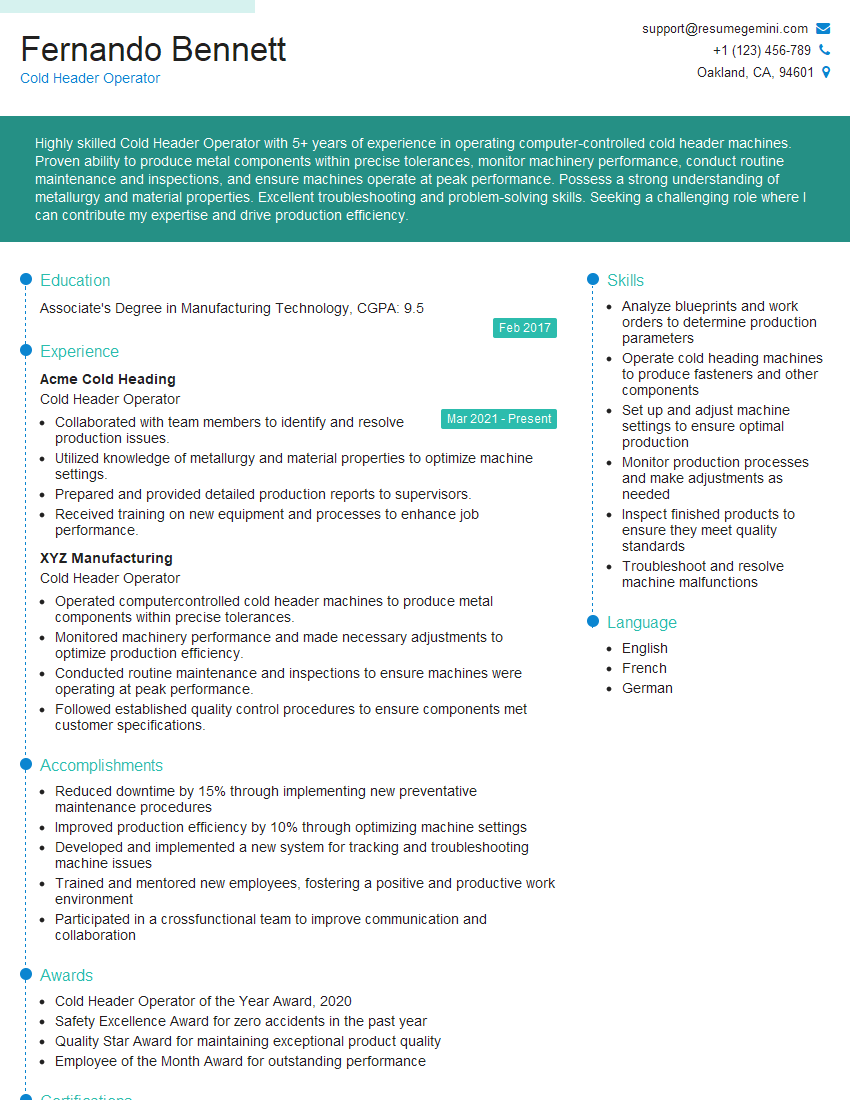

Fernando Bennett

Cold Header Operator

Summary

Highly skilled Cold Header Operator with 5+ years of experience in operating computer-controlled cold header machines. Proven ability to produce metal components within precise tolerances, monitor machinery performance, conduct routine maintenance and inspections, and ensure machines operate at peak performance. Possess a strong understanding of metallurgy and material properties. Excellent troubleshooting and problem-solving skills. Seeking a challenging role where I can contribute my expertise and drive production efficiency.

Education

Associate’s Degree in Manufacturing Technology

February 2017

Skills

- Analyze blueprints and work orders to determine production parameters

- Operate cold heading machines to produce fasteners and other components

- Set up and adjust machine settings to ensure optimal production

- Monitor production processes and make adjustments as needed

- Inspect finished products to ensure they meet quality standards

- Troubleshoot and resolve machine malfunctions

Work Experience

Cold Header Operator

- Collaborated with team members to identify and resolve production issues.

- Utilized knowledge of metallurgy and material properties to optimize machine settings.

- Prepared and provided detailed production reports to supervisors.

- Received training on new equipment and processes to enhance job performance.

Cold Header Operator

- Operated computercontrolled cold header machines to produce metal components within precise tolerances.

- Monitored machinery performance and made necessary adjustments to optimize production efficiency.

- Conducted routine maintenance and inspections to ensure machines were operating at peak performance.

- Followed established quality control procedures to ensure components met customer specifications.

Accomplishments

- Reduced downtime by 15% through implementing new preventative maintenance procedures

- Improved production efficiency by 10% through optimizing machine settings

- Developed and implemented a new system for tracking and troubleshooting machine issues

- Trained and mentored new employees, fostering a positive and productive work environment

- Participated in a crossfunctional team to improve communication and collaboration

Awards

- Cold Header Operator of the Year Award, 2020

- Safety Excellence Award for zero accidents in the past year

- Quality Star Award for maintaining exceptional product quality

- Employee of the Month Award for outstanding performance

Certificates

- Certified Cold Header Operator (CCHO)

- OSHA 10-Hour Safety Certification

- ISO 9001:2015 Quality Management System Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cold Header Operator

- Highlight your experience and skills in operating cold header machines.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on production efficiency.

- Showcase your knowledge of metallurgy and material properties, as well as your ability to troubleshoot and resolve production issues.

- Emphasize your teamwork and problem-solving abilities.

Essential Experience Highlights for a Strong Cold Header Operator Resume

- Operate computer-controlled cold header machines to produce metal components within precise tolerances.

- Monitor machinery performance and make necessary adjustments to optimize production efficiency.

- Conduct routine maintenance and inspections to ensure machines are operating at peak performance.

- Follow established quality control procedures to ensure components meet customer specifications.

- Collaborate with team members to identify and resolve production issues.

- Utilized knowledge of metallurgy and material properties to optimize machine settings.

- Prepared and provided detailed production reports to supervisors.

Frequently Asked Questions (FAQ’s) For Cold Header Operator

What is a Cold Header Operator?

A Cold Header Operator is a skilled professional responsible for operating computer-controlled cold header machines to produce metal components within precise tolerances. They monitor machinery performance, conduct routine maintenance and inspections, and ensure machines operate at peak performance. Cold Header Operators also follow established quality control procedures to ensure components meet customer specifications.

What are the key skills required for a Cold Header Operator?

Key skills required for a Cold Header Operator include the ability to operate computer-controlled cold header machines, monitor machinery performance, conduct routine maintenance and inspections, follow established quality control procedures, troubleshoot and resolve production issues, and collaborate with team members.

What are the career prospects for a Cold Header Operator?

Cold Header Operators with the right skills and experience can advance their careers by becoming supervisors or managers. They may also specialize in a particular area of cold heading, such as tooling or metallurgy.

What is the work environment of a Cold Header Operator?

Cold Header Operators typically work in manufacturing environments, where they operate machines that produce metal components. They may work in teams or independently, and may be required to work overtime or on weekends to meet production deadlines.

What are the safety precautions that a Cold Header Operator should take?

Cold Header Operators should always wear appropriate safety gear, such as safety glasses, gloves, and earplugs. They should also be aware of the potential hazards of working with machinery, and should follow established safety procedures.

What are the educational requirements for a Cold Header Operator?

While there are no specific educational requirements for a Cold Header Operator, many employers prefer candidates with a high school diploma or equivalent. Some employers may also prefer candidates with experience in manufacturing or a related field.

What are the salary expectations for a Cold Header Operator?

Salary expectations for a Cold Header Operator can vary depending on experience, skills, and location. According to Indeed, the average salary for a Cold Header Operator in the United States is $21.60 per hour.

What are the job outlook prospects for a Cold Header Operator?

The job outlook for Cold Header Operators is expected to be good over the next few years. As the manufacturing industry continues to grow, there will be an increasing demand for skilled workers who can operate and maintain cold header machines.