Are you a seasoned Cold Mill Operator seeking a new career path? Discover our professionally built Cold Mill Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

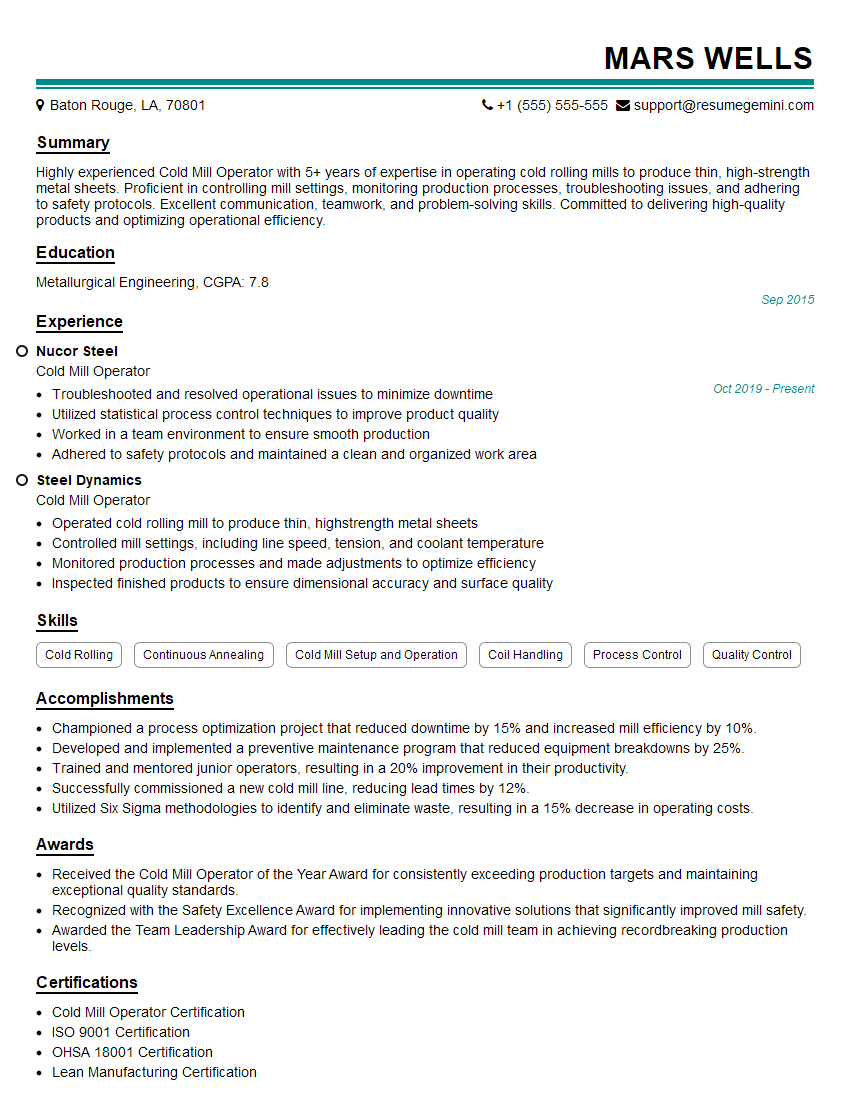

Mars Wells

Cold Mill Operator

Summary

Highly experienced Cold Mill Operator with 5+ years of expertise in operating cold rolling mills to produce thin, high-strength metal sheets. Proficient in controlling mill settings, monitoring production processes, troubleshooting issues, and adhering to safety protocols. Excellent communication, teamwork, and problem-solving skills. Committed to delivering high-quality products and optimizing operational efficiency.

Education

Metallurgical Engineering

September 2015

Skills

- Cold Rolling

- Continuous Annealing

- Cold Mill Setup and Operation

- Coil Handling

- Process Control

- Quality Control

Work Experience

Cold Mill Operator

- Troubleshooted and resolved operational issues to minimize downtime

- Utilized statistical process control techniques to improve product quality

- Worked in a team environment to ensure smooth production

- Adhered to safety protocols and maintained a clean and organized work area

Cold Mill Operator

- Operated cold rolling mill to produce thin, highstrength metal sheets

- Controlled mill settings, including line speed, tension, and coolant temperature

- Monitored production processes and made adjustments to optimize efficiency

- Inspected finished products to ensure dimensional accuracy and surface quality

Accomplishments

- Championed a process optimization project that reduced downtime by 15% and increased mill efficiency by 10%.

- Developed and implemented a preventive maintenance program that reduced equipment breakdowns by 25%.

- Trained and mentored junior operators, resulting in a 20% improvement in their productivity.

- Successfully commissioned a new cold mill line, reducing lead times by 12%.

- Utilized Six Sigma methodologies to identify and eliminate waste, resulting in a 15% decrease in operating costs.

Awards

- Received the Cold Mill Operator of the Year Award for consistently exceeding production targets and maintaining exceptional quality standards.

- Recognized with the Safety Excellence Award for implementing innovative solutions that significantly improved mill safety.

- Awarded the Team Leadership Award for effectively leading the cold mill team in achieving recordbreaking production levels.

Certificates

- Cold Mill Operator Certification

- ISO 9001 Certification

- OHSA 18001 Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cold Mill Operator

Highlight relevant skills and experience:

Emphasize your proficiency in cold rolling mill operations, including setup, control, troubleshooting, and quality control.Quantify your accomplishments:

Use specific metrics to demonstrate the impact of your work, such as improvements in production efficiency, reduction in downtime, or peningkatan in product quality.Showcase your problem-solving abilities:

Describe instances where you successfully identified and resolved operational issues, demonstrating your critical thinking and analytical skills.Demonstrate your commitment to safety:

Highlight your adherence to safety protocols and your role in maintaining a clean and organized work area.

Essential Experience Highlights for a Strong Cold Mill Operator Resume

- Operated cold rolling mills to produce thin, high-strength metal sheets of varying thicknesses and widths.

- Controlled mill settings, including line speed, tension, and coolant temperature, to achieve desired product specifications.

- Monitored production processes closely, made adjustments, and implemented corrective actions to optimize efficiency and minimize downtime.

- Inspected finished products thoroughly to ensure dimensional accuracy, surface quality, and adherence to customer requirements.

- Troubleshooted and resolved operational issues promptly, minimizing disruptions and maintaining smooth production flow.

- Utilized statistical process control (SPC) techniques to monitor and improve product quality, reduce variability, and enhance consistency.

Frequently Asked Questions (FAQ’s) For Cold Mill Operator

What are the primary responsibilities of a Cold Mill Operator?

Cold Mill Operators are responsible for operating cold rolling mills to produce thin, high-strength metal sheets. They control mill settings, monitor production processes, troubleshoot issues, inspect finished products, and ensure adherence to safety protocols.

What skills are essential for a successful Cold Mill Operator?

Cold Mill Operators require a combination of technical expertise and soft skills, including proficiency in cold rolling operations, process control, quality control, troubleshooting, teamwork, and safety awareness.

What educational background is required to become a Cold Mill Operator?

While formal education requirements may vary, many Cold Mill Operators hold degrees in Metallurgical Engineering or related fields.

What are the career prospects for Cold Mill Operators?

Cold Mill Operators can advance to supervisory roles, such as Cold Rolling Foreman or Production Manager, or specialize in areas such as quality control or process improvement.

What is the typical work environment for a Cold Mill Operator?

Cold Mill Operators typically work in industrial settings, operating cold rolling mills within production facilities. The work environment may involve exposure to noise, heavy machinery, and potential hazards, requiring the use of appropriate safety gear.

How can I improve my chances of getting hired as a Cold Mill Operator?

To increase your chances of getting hired, focus on acquiring relevant skills and experience through internships, apprenticeships, or on-the-job training. Additionally, obtaining industry certifications and demonstrating a commitment to safety and quality can enhance your competitiveness.