Are you a seasoned Collet Driller seeking a new career path? Discover our professionally built Collet Driller Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

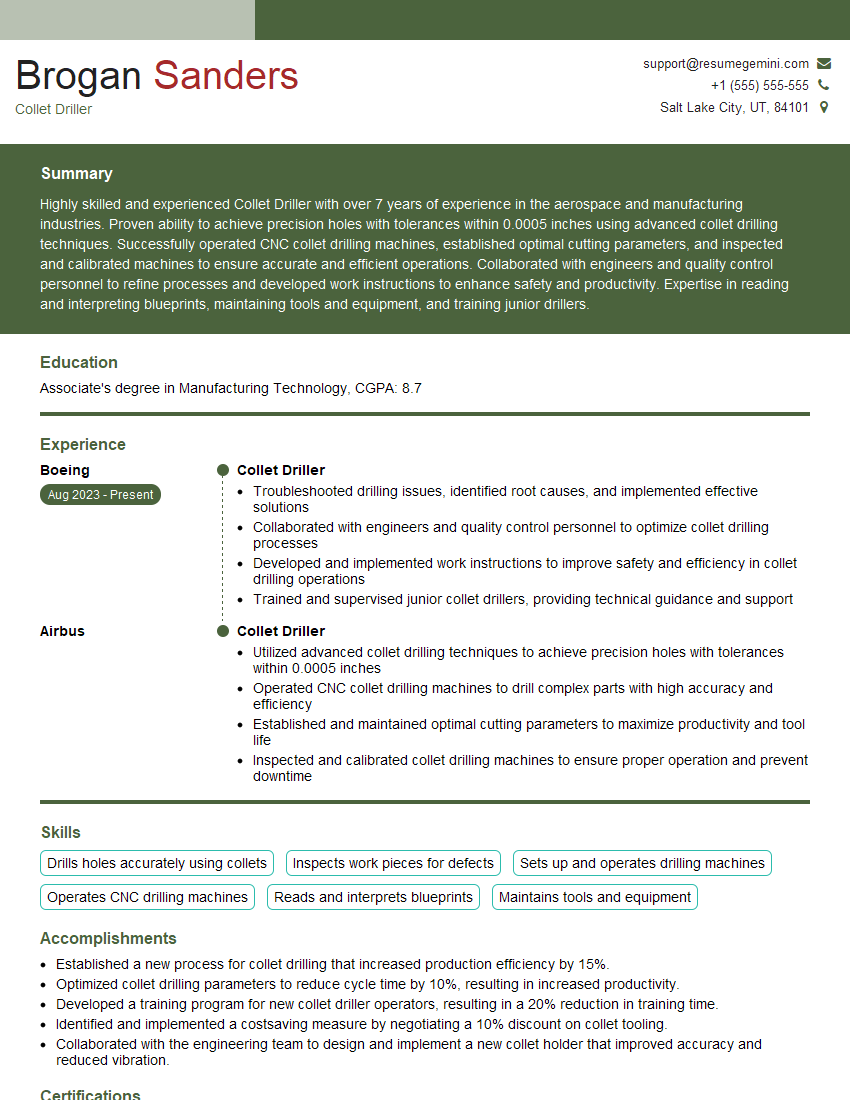

Brogan Sanders

Collet Driller

Summary

Highly skilled and experienced Collet Driller with over 7 years of experience in the aerospace and manufacturing industries. Proven ability to achieve precision holes with tolerances within 0.0005 inches using advanced collet drilling techniques. Successfully operated CNC collet drilling machines, established optimal cutting parameters, and inspected and calibrated machines to ensure accurate and efficient operations. Collaborated with engineers and quality control personnel to refine processes and developed work instructions to enhance safety and productivity. Expertise in reading and interpreting blueprints, maintaining tools and equipment, and training junior drillers.

Education

Associate’s degree in Manufacturing Technology

July 2019

Skills

- Drills holes accurately using collets

- Inspects work pieces for defects

- Sets up and operates drilling machines

- Operates CNC drilling machines

- Reads and interprets blueprints

- Maintains tools and equipment

Work Experience

Collet Driller

- Troubleshooted drilling issues, identified root causes, and implemented effective solutions

- Collaborated with engineers and quality control personnel to optimize collet drilling processes

- Developed and implemented work instructions to improve safety and efficiency in collet drilling operations

- Trained and supervised junior collet drillers, providing technical guidance and support

Collet Driller

- Utilized advanced collet drilling techniques to achieve precision holes with tolerances within 0.0005 inches

- Operated CNC collet drilling machines to drill complex parts with high accuracy and efficiency

- Established and maintained optimal cutting parameters to maximize productivity and tool life

- Inspected and calibrated collet drilling machines to ensure proper operation and prevent downtime

Accomplishments

- Established a new process for collet drilling that increased production efficiency by 15%.

- Optimized collet drilling parameters to reduce cycle time by 10%, resulting in increased productivity.

- Developed a training program for new collet driller operators, resulting in a 20% reduction in training time.

- Identified and implemented a costsaving measure by negotiating a 10% discount on collet tooling.

- Collaborated with the engineering team to design and implement a new collet holder that improved accuracy and reduced vibration.

Certificates

- Certified Collet Driller

- ISO 9001:2015 Certified

- ASME B18.9 Certified

- OSHA 10-Hour General Industry Safety Certified

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Collet Driller

1. Highlight Your Precision and Accuracy Skills:

Collet drilling requires extreme precision and accuracy. Emphasize your ability to consistently achieve tight tolerances and meet demanding specifications.

2. Showcase Your Technical Expertise:

Discuss your proficiency in operating CNC collet drilling machines, setting up workpieces, and selecting appropriate cutting parameters. Mention any specific techniques or technologies you are familiar with.

3. Quantify Your Achievements:

Use numbers and metrics to demonstrate your contributions. For example, state the number of parts you drilled within a specific tolerance range or the percentage of downtime you reduced through proactive maintenance.

4. Emphasize Safety and Quality Control:

Highlight your commitment to adhering to safety protocols and maintaining high-quality standards. Mention your experience in inspecting and calibrating equipment, as well as your involvement in developing work instructions to enhance operational efficiency and minimize errors.

Essential Experience Highlights for a Strong Collet Driller Resume

- Utilized advanced collet drilling techniques to achieve precision holes with tolerances within 0.0005 inches.

- Operated CNC collet drilling machines to drill complex parts with high accuracy and efficiency.

- Established and maintained optimal cutting parameters to maximize productivity and tool life.

- Inspected and calibrated collet drilling machines to ensure proper operation and prevent downtime.

- Troubleshooted drilling issues, identified root causes, and implemented effective solutions.

- Collaborated with engineers and quality control personnel to optimize collet drilling processes.

- Developed and implemented work instructions to improve safety and efficiency in collet drilling operations.

Frequently Asked Questions (FAQ’s) For Collet Driller

What is the primary role of a Collet Driller?

A Collet Driller is responsible for operating collet drilling machines to create precise holes in various materials. They ensure accurate hole dimensions, maintain equipment, and troubleshoot drilling issues.

What industries commonly employ Collet Drillers?

Collet Drillers are in demand in industries such as aerospace, automotive, manufacturing, and electronics, where precision drilling is crucial for component fabrication.

What are the key skills required for a successful Collet Driller?

Essential skills include proficiency in operating CNC collet drilling machines, understanding of cutting parameters, ability to read and interpret blueprints, and attention to detail.

What is the career progression path for Collet Drillers?

With experience and additional training, Collet Drillers can advance to roles such as CNC Machinist, Machine Supervisor, or Quality Control Inspector.

What are the challenges faced by Collet Drillers?

Common challenges include meeting tight tolerances, working with delicate materials, and ensuring machine accuracy. They also need to stay updated with advancements in drilling technology.

How can I improve my resume as a Collet Driller?

Highlight your precision drilling skills, relevant experience, and certifications. Use specific examples and quantifiable results to showcase your capabilities.