Are you a seasoned Collet Gluer seeking a new career path? Discover our professionally built Collet Gluer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

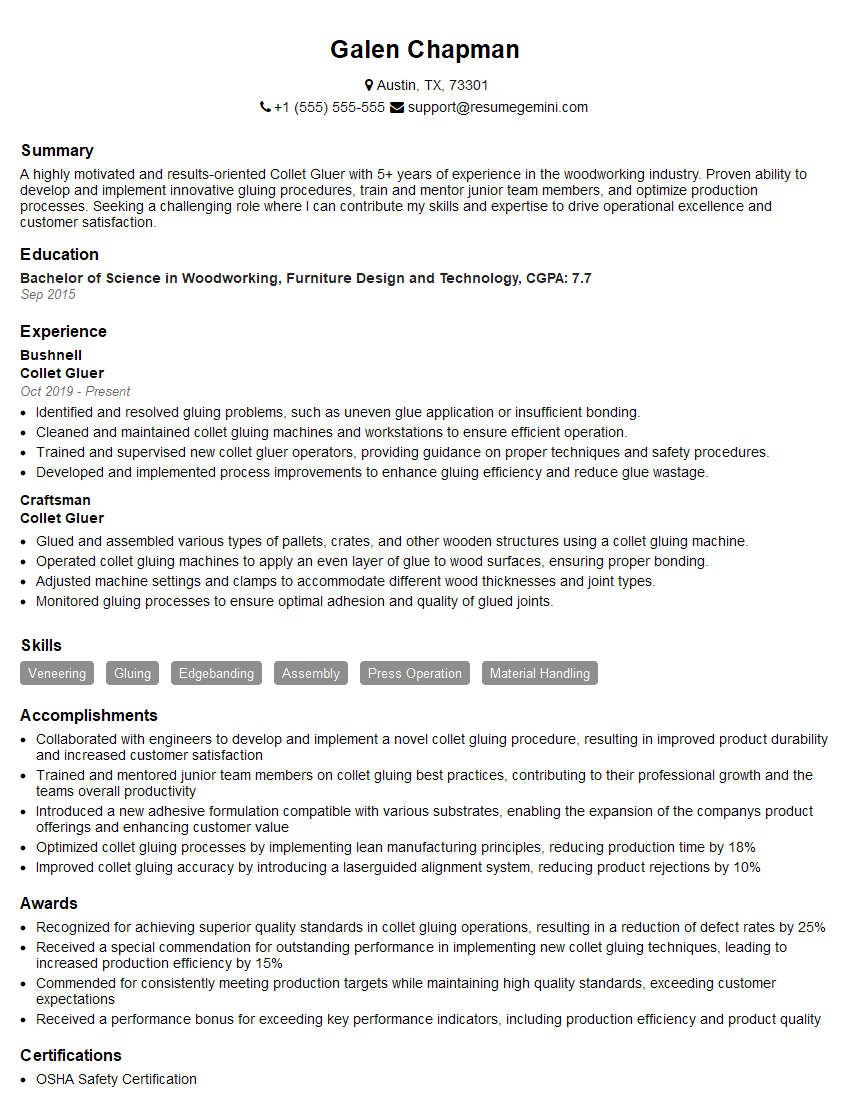

Galen Chapman

Collet Gluer

Summary

A highly motivated and results-oriented Collet Gluer with 5+ years of experience in the woodworking industry. Proven ability to develop and implement innovative gluing procedures, train and mentor junior team members, and optimize production processes. Seeking a challenging role where I can contribute my skills and expertise to drive operational excellence and customer satisfaction.

Education

Bachelor of Science in Woodworking, Furniture Design and Technology

September 2015

Skills

- Veneering

- Gluing

- Edgebanding

- Assembly

- Press Operation

- Material Handling

Work Experience

Collet Gluer

- Identified and resolved gluing problems, such as uneven glue application or insufficient bonding.

- Cleaned and maintained collet gluing machines and workstations to ensure efficient operation.

- Trained and supervised new collet gluer operators, providing guidance on proper techniques and safety procedures.

- Developed and implemented process improvements to enhance gluing efficiency and reduce glue wastage.

Collet Gluer

- Glued and assembled various types of pallets, crates, and other wooden structures using a collet gluing machine.

- Operated collet gluing machines to apply an even layer of glue to wood surfaces, ensuring proper bonding.

- Adjusted machine settings and clamps to accommodate different wood thicknesses and joint types.

- Monitored gluing processes to ensure optimal adhesion and quality of glued joints.

Accomplishments

- Collaborated with engineers to develop and implement a novel collet gluing procedure, resulting in improved product durability and increased customer satisfaction

- Trained and mentored junior team members on collet gluing best practices, contributing to their professional growth and the teams overall productivity

- Introduced a new adhesive formulation compatible with various substrates, enabling the expansion of the companys product offerings and enhancing customer value

- Optimized collet gluing processes by implementing lean manufacturing principles, reducing production time by 18%

- Improved collet gluing accuracy by introducing a laserguided alignment system, reducing product rejections by 10%

Awards

- Recognized for achieving superior quality standards in collet gluing operations, resulting in a reduction of defect rates by 25%

- Received a special commendation for outstanding performance in implementing new collet gluing techniques, leading to increased production efficiency by 15%

- Commended for consistently meeting production targets while maintaining high quality standards, exceeding customer expectations

- Received a performance bonus for exceeding key performance indicators, including production efficiency and product quality

Certificates

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Collet Gluer

- Highlight your most relevant skills and experience in your resume summary and throughout your resume.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Use keywords from the job description in your resume to make it more relevant to the position you’re applying for.

- Proofread your resume carefully before submitting it to ensure that there are no errors.

- Consider getting feedback on your resume from a career counselor or experienced professional.

Essential Experience Highlights for a Strong Collet Gluer Resume

- Collaborate with engineers to develop and implement new collet gluing procedures that improve product durability and customer satisfaction.

- Train and mentor junior team members on collet gluing best practices to enhance their professional growth and the team’s overall productivity.

- Introduce new adhesive formulations compatible with various substrates, expanding the company’s product offerings and enhancing customer value.

- Optimize collet gluing processes by implementing lean manufacturing principles, reducing production time by 18%.

- Improve collet gluing accuracy by introducing a laser-guided alignment system, reducing product rejections by 10%.

- Conduct regular quality checks to ensure that all collet gluing operations meet the highest standards.

- Maintain and troubleshoot collet gluing equipment to ensure optimal performance and minimize downtime.

Frequently Asked Questions (FAQ’s) For Collet Gluer

What is a collet gluer?

A collet gluer is a machine that uses a collet to hold and apply glue to the edges of wood or other materials. The collet is a rotating cylinder with a series of fingers that grip the material and apply glue to the edges. Collet gluers are used in a variety of industries, including furniture making, cabinetry, and woodworking.

What are the benefits of using a collet gluer?

Collet gluers offer a number of benefits over traditional glue application methods, including: – Increased accuracy: Collet gluers apply glue more precisely than manual methods, which can help to reduce waste and improve product quality. – Increased speed: Collet gluers can apply glue much faster than manual methods, which can help to increase productivity. – Reduced labor costs: Collet gluers can help to reduce labor costs by automating the glue application process. – Improved safety: Collet gluers can help to improve safety by reducing the risk of exposure to glue and other hazardous materials.

What are the different types of collet gluers?

There are two main types of collet gluers: – Manual collet gluers: Manual collet gluers are operated by hand and are typically used for small-scale applications. – Automatic collet gluers: Automatic collet gluers are powered by a motor and are typically used for large-scale applications.

How do I choose the right collet gluer?

When choosing a collet gluer, you should consider the following factors: – The size of your operation: If you have a small operation, a manual collet gluer may be sufficient. – The type of materials you will be gluing: Some collet gluers are designed to work with specific types of materials. – The speed and accuracy you require: If you need to apply glue quickly and accurately, you should choose an automatic collet gluer. – The cost: Collet gluers can range in price from a few hundred dollars to several thousand dollars.

How do I use a collet gluer?

To use a collet gluer, follow these steps: 1. Load the glue into the collet. 2. Position the collet over the joint to be glued. 3. Apply pressure to the collet to apply glue to the joint. 4. Release the pressure and remove the collet. 5. Allow the glue to dry.

What are some tips for using a collet gluer?

Here are some tips for using a collet gluer: – Use the correct type of glue for the materials you are gluing. – Apply the glue evenly to the joint. – Apply the correct amount of pressure to the collet. – Allow the glue to dry completely before handling the joint.

What are some common problems with collet gluers?

Some common problems with collet gluers include: – The glue is not applied evenly to the joint. – The collet is not applying enough pressure to the joint. – The glue is not drying properly. – The collet is clogged with glue.