Are you a seasoned Compressed Gas Equipment Mechanic seeking a new career path? Discover our professionally built Compressed Gas Equipment Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

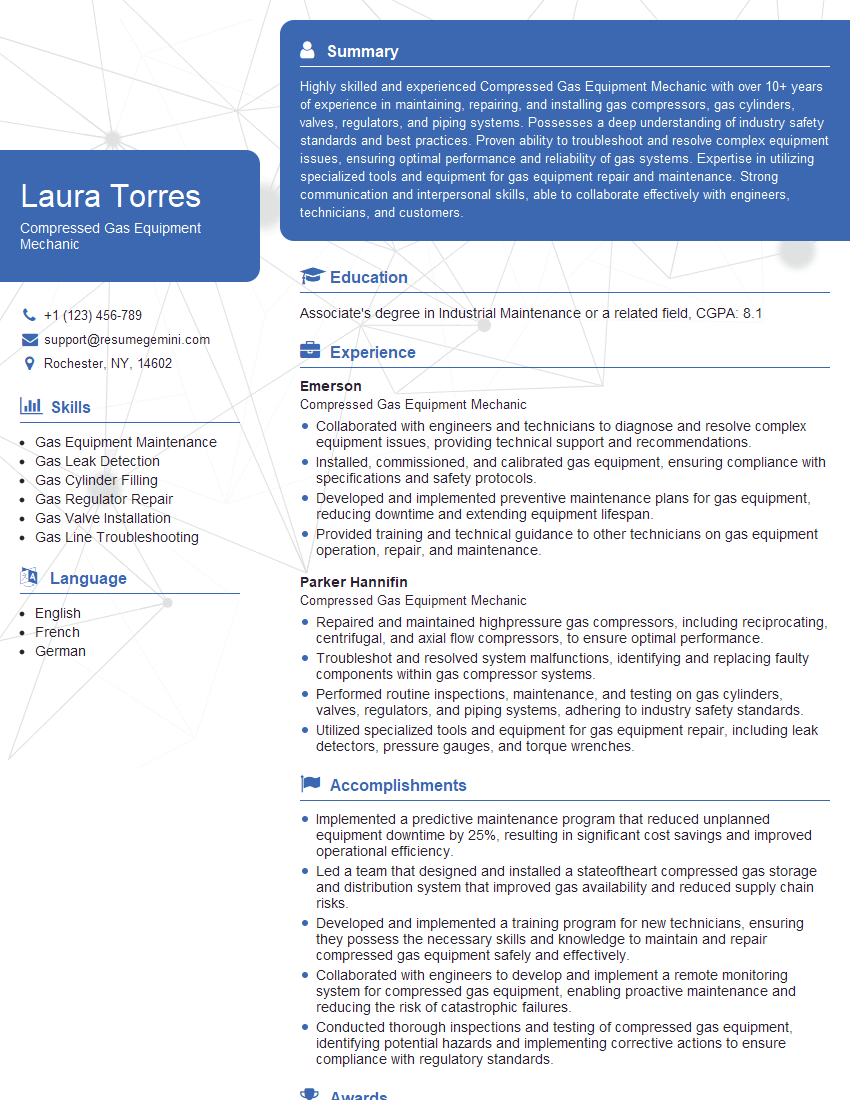

Laura Torres

Compressed Gas Equipment Mechanic

Summary

Highly skilled and experienced Compressed Gas Equipment Mechanic with over 10+ years of experience in maintaining, repairing, and installing gas compressors, gas cylinders, valves, regulators, and piping systems. Possesses a deep understanding of industry safety standards and best practices. Proven ability to troubleshoot and resolve complex equipment issues, ensuring optimal performance and reliability of gas systems. Expertise in utilizing specialized tools and equipment for gas equipment repair and maintenance. Strong communication and interpersonal skills, able to collaborate effectively with engineers, technicians, and customers.

Education

Associate’s degree in Industrial Maintenance or a related field

May 2016

Skills

- Gas Equipment Maintenance

- Gas Leak Detection

- Gas Cylinder Filling

- Gas Regulator Repair

- Gas Valve Installation

- Gas Line Troubleshooting

Work Experience

Compressed Gas Equipment Mechanic

- Collaborated with engineers and technicians to diagnose and resolve complex equipment issues, providing technical support and recommendations.

- Installed, commissioned, and calibrated gas equipment, ensuring compliance with specifications and safety protocols.

- Developed and implemented preventive maintenance plans for gas equipment, reducing downtime and extending equipment lifespan.

- Provided training and technical guidance to other technicians on gas equipment operation, repair, and maintenance.

Compressed Gas Equipment Mechanic

- Repaired and maintained highpressure gas compressors, including reciprocating, centrifugal, and axial flow compressors, to ensure optimal performance.

- Troubleshot and resolved system malfunctions, identifying and replacing faulty components within gas compressor systems.

- Performed routine inspections, maintenance, and testing on gas cylinders, valves, regulators, and piping systems, adhering to industry safety standards.

- Utilized specialized tools and equipment for gas equipment repair, including leak detectors, pressure gauges, and torque wrenches.

Accomplishments

- Implemented a predictive maintenance program that reduced unplanned equipment downtime by 25%, resulting in significant cost savings and improved operational efficiency.

- Led a team that designed and installed a stateoftheart compressed gas storage and distribution system that improved gas availability and reduced supply chain risks.

- Developed and implemented a training program for new technicians, ensuring they possess the necessary skills and knowledge to maintain and repair compressed gas equipment safely and effectively.

- Collaborated with engineers to develop and implement a remote monitoring system for compressed gas equipment, enabling proactive maintenance and reducing the risk of catastrophic failures.

- Conducted thorough inspections and testing of compressed gas equipment, identifying potential hazards and implementing corrective actions to ensure compliance with regulatory standards.

Awards

- Recognized by the Compressed Gas Association (CGA) for outstanding contributions to the advancement of compressed gas equipment safety standards.

- Received the Safety Excellence Award from the National Board of Pressure Vessel Inspectors (NBPI) for implementing innovative safety measures in the compressed gas equipment industry.

- Awarded the Certificate of Merit from the American Society of Mechanical Engineers (ASME) for developing a novel design for highpressure gas regulators.

- Honored with the Employee of the Year Award for exceptional performance in troubleshooting and repairing complex compressed gas equipment malfunctions.

Certificates

- Compressed Gas Association (CGA) Certified Gas Equipment Technician

- National Board of Boiler and Pressure Vessel Inspectors (NBBI) Commissioned Inspector

- American Welding Society (AWS) Certified Welder

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Compressed Gas Equipment Mechanic

- Highlight your technical skills and experience in maintaining and repairing gas equipment.

- Showcase your knowledge of industry safety standards and regulations.

- Provide specific examples of complex equipment issues you have resolved.

- Quantify your accomplishments, such as the number of gas compressors you have repaired or the amount of downtime you have reduced.

Essential Experience Highlights for a Strong Compressed Gas Equipment Mechanic Resume

- Repair and maintain high-pressure gas compressors, including reciprocating, centrifugal, and axial flow compressors.

- Troubleshoot and resolve system malfunctions, identifying and replacing faulty components within gas compressor systems.

- Perform routine inspections, maintenance, and testing on gas cylinders, valves, regulators, and piping systems, adhering to industry safety standards.

- Utilize specialized tools and equipment for gas equipment repair, including leak detectors, pressure gauges, and torque wrenches.

- Install, commission, and calibrate gas equipment, ensuring compliance with specifications and safety protocols.

- Collaborate with engineers and technicians to diagnose and resolve complex equipment issues, providing technical support and recommendations.

- Develop and implement preventive maintenance plans for gas equipment, reducing downtime and extending equipment lifespan.

Frequently Asked Questions (FAQ’s) For Compressed Gas Equipment Mechanic

What is a Compressed Gas Equipment Mechanic?

A Compressed Gas Equipment Mechanic is a skilled professional responsible for maintaining, repairing, and installing gas compressors, gas cylinders, valves, regulators, and piping systems. They ensure the safe and efficient operation of gas equipment in various industries.

What are the key skills required for a Compressed Gas Equipment Mechanic?

Key skills include: gas equipment maintenance, gas leak detection, gas cylinder filling, gas regulator repair, gas valve installation, gas line troubleshooting, and adherence to safety standards.

What are the career opportunities for a Compressed Gas Equipment Mechanic?

Compressed Gas Equipment Mechanics can work in various industries, including manufacturing, energy, healthcare, and construction. They can also pursue specialized roles such as maintenance supervisor or technical trainer.

What are the educational requirements for a Compressed Gas Equipment Mechanic?

Most Compressed Gas Equipment Mechanics have an associate’s degree in industrial maintenance or a related field. Some may also have additional certifications or training in gas equipment repair.

What is the job outlook for Compressed Gas Equipment Mechanics?

The job outlook is expected to be favorable in the coming years due to the increasing demand for skilled technicians in the gas industry.

What are the safety precautions for Compressed Gas Equipment Mechanics?

Compressed Gas Equipment Mechanics must follow strict safety protocols, including wearing protective gear, following lockout/tagout procedures, and adhering to industry regulations.

What are the challenges faced by Compressed Gas Equipment Mechanics?

Compressed Gas Equipment Mechanics may encounter challenges such as working with high-pressure systems, hazardous materials, and tight deadlines.

What are the benefits of being a Compressed Gas Equipment Mechanic?

Benefits include competitive salaries, opportunities for advancement, job security, and the satisfaction of working with specialized equipment.