Are you a seasoned Computer Numerical Control Drilling Operator (CNC Drilling Operator) seeking a new career path? Discover our professionally built Computer Numerical Control Drilling Operator (CNC Drilling Operator) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

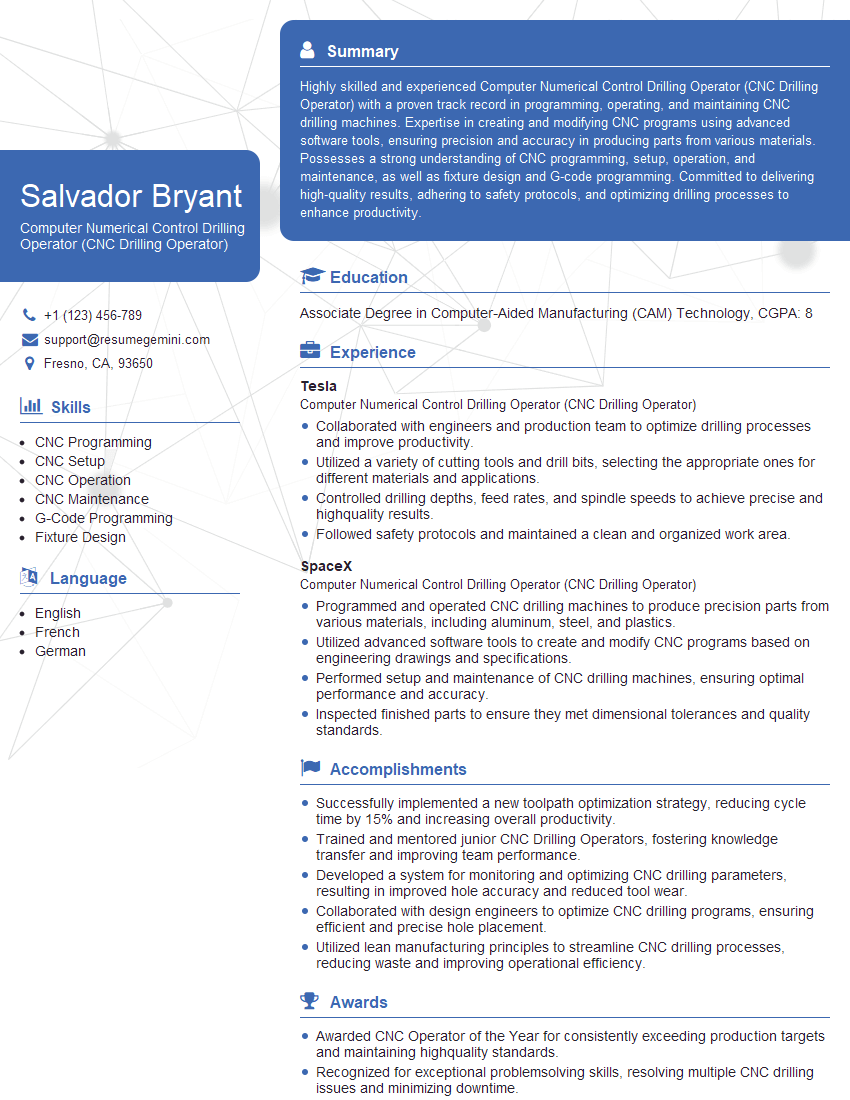

Salvador Bryant

Computer Numerical Control Drilling Operator (CNC Drilling Operator)

Summary

Highly skilled and experienced Computer Numerical Control Drilling Operator (CNC Drilling Operator) with a proven track record in programming, operating, and maintaining CNC drilling machines. Expertise in creating and modifying CNC programs using advanced software tools, ensuring precision and accuracy in producing parts from various materials. Possesses a strong understanding of CNC programming, setup, operation, and maintenance, as well as fixture design and G-code programming. Committed to delivering high-quality results, adhering to safety protocols, and optimizing drilling processes to enhance productivity.

Education

Associate Degree in Computer-Aided Manufacturing (CAM) Technology

June 2018

Skills

- CNC Programming

- CNC Setup

- CNC Operation

- CNC Maintenance

- G-Code Programming

- Fixture Design

Work Experience

Computer Numerical Control Drilling Operator (CNC Drilling Operator)

- Collaborated with engineers and production team to optimize drilling processes and improve productivity.

- Utilized a variety of cutting tools and drill bits, selecting the appropriate ones for different materials and applications.

- Controlled drilling depths, feed rates, and spindle speeds to achieve precise and highquality results.

- Followed safety protocols and maintained a clean and organized work area.

Computer Numerical Control Drilling Operator (CNC Drilling Operator)

- Programmed and operated CNC drilling machines to produce precision parts from various materials, including aluminum, steel, and plastics.

- Utilized advanced software tools to create and modify CNC programs based on engineering drawings and specifications.

- Performed setup and maintenance of CNC drilling machines, ensuring optimal performance and accuracy.

- Inspected finished parts to ensure they met dimensional tolerances and quality standards.

Accomplishments

- Successfully implemented a new toolpath optimization strategy, reducing cycle time by 15% and increasing overall productivity.

- Trained and mentored junior CNC Drilling Operators, fostering knowledge transfer and improving team performance.

- Developed a system for monitoring and optimizing CNC drilling parameters, resulting in improved hole accuracy and reduced tool wear.

- Collaborated with design engineers to optimize CNC drilling programs, ensuring efficient and precise hole placement.

- Utilized lean manufacturing principles to streamline CNC drilling processes, reducing waste and improving operational efficiency.

Awards

- Awarded CNC Operator of the Year for consistently exceeding production targets and maintaining highquality standards.

- Recognized for exceptional problemsolving skills, resolving multiple CNC drilling issues and minimizing downtime.

- Achieved Master Craftsman certification for proficiency in CNC drilling operations and adherence to industry best practices.

- Honored with the Safety Excellence Award for maintaining an exemplary safety record and promoting workplace safety standards.

Certificates

- Certified CNC Programmer

- Certified CNC Operator

- Certified GD&T Professional

- Certified Quality Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Computer Numerical Control Drilling Operator (CNC Drilling Operator)

- Highlight your proficiency in CNC programming, setup, operation, and maintenance

- Showcase your experience in creating and modifying CNC programs using advanced software tools

- Emphasize your ability to work independently and as part of a team to optimize drilling processes and enhance productivity

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact

- Proofread your resume carefully for any errors in grammar or spelling

Essential Experience Highlights for a Strong Computer Numerical Control Drilling Operator (CNC Drilling Operator) Resume

- Programmed and operated CNC drilling machines to produce precision parts from aluminum, steel, plastics, and other materials

- Utilized advanced software tools to create and modify CNC programs based on engineering drawings and specifications

- Performed setup and maintenance of CNC drilling machines, ensuring optimal performance and accuracy

- Inspected finished parts to ensure they met dimensional tolerances and quality standards

- Collaborated with engineers and production team to optimize drilling processes and improve productivity

Frequently Asked Questions (FAQ’s) For Computer Numerical Control Drilling Operator (CNC Drilling Operator)

What are the key skills required for a Computer Numerical Control Drilling Operator?

Essential skills for a CNC Drilling Operator include CNC Programming, CNC Setup, CNC Operation, CNC Maintenance, G-Code Programming, and Fixture Design.

What is the educational background required for a Computer Numerical Control Drilling Operator?

Typically, an Associate Degree in Computer-Aided Manufacturing (CAM) Technology or a related field is required for this role.

What are the career prospects for a Computer Numerical Control Drilling Operator?

With experience and additional training, CNC Drilling Operators can advance to supervisory or management positions, or specialize in specific areas such as programming or maintenance.

What is the work environment like for a Computer Numerical Control Drilling Operator?

CNC Drilling Operators typically work in manufacturing environments, operating CNC machines in workshops or factories. They may work independently or as part of a team, and may be required to work shifts.

What are the safety precautions that should be taken when operating a CNC Drilling Machine?

Always wear appropriate safety gear, including safety glasses, gloves, and ear protection. Ensure the machine is properly grounded and maintained. Never reach into the machine while it is operating. Keep the work area clean and free of debris.