Are you a seasoned Concrete Placement Equipment Operator seeking a new career path? Discover our professionally built Concrete Placement Equipment Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

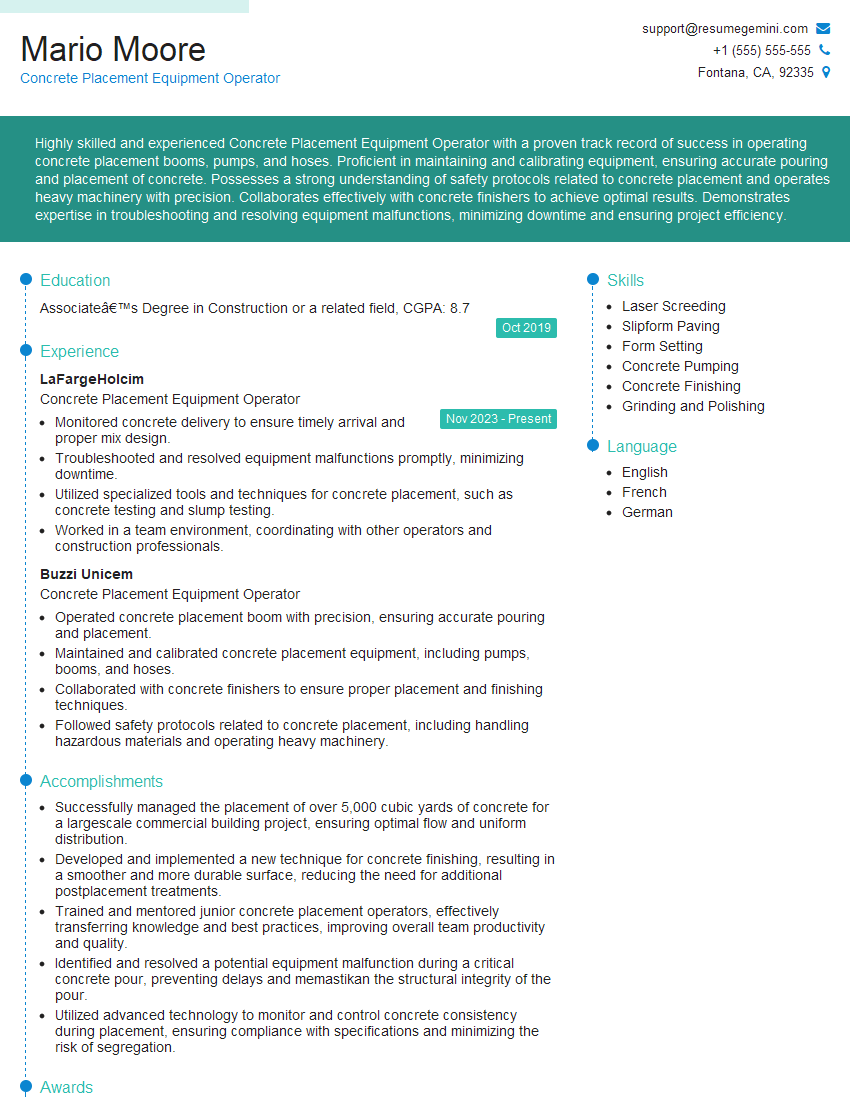

Mario Moore

Concrete Placement Equipment Operator

Summary

Highly skilled and experienced Concrete Placement Equipment Operator with a proven track record of success in operating concrete placement booms, pumps, and hoses. Proficient in maintaining and calibrating equipment, ensuring accurate pouring and placement of concrete. Possesses a strong understanding of safety protocols related to concrete placement and operates heavy machinery with precision. Collaborates effectively with concrete finishers to achieve optimal results. Demonstrates expertise in troubleshooting and resolving equipment malfunctions, minimizing downtime and ensuring project efficiency.

Education

Associate’s Degree in Construction or a related field

October 2019

Skills

- Laser Screeding

- Slipform Paving

- Form Setting

- Concrete Pumping

- Concrete Finishing

- Grinding and Polishing

Work Experience

Concrete Placement Equipment Operator

- Monitored concrete delivery to ensure timely arrival and proper mix design.

- Troubleshooted and resolved equipment malfunctions promptly, minimizing downtime.

- Utilized specialized tools and techniques for concrete placement, such as concrete testing and slump testing.

- Worked in a team environment, coordinating with other operators and construction professionals.

Concrete Placement Equipment Operator

- Operated concrete placement boom with precision, ensuring accurate pouring and placement.

- Maintained and calibrated concrete placement equipment, including pumps, booms, and hoses.

- Collaborated with concrete finishers to ensure proper placement and finishing techniques.

- Followed safety protocols related to concrete placement, including handling hazardous materials and operating heavy machinery.

Accomplishments

- Successfully managed the placement of over 5,000 cubic yards of concrete for a largescale commercial building project, ensuring optimal flow and uniform distribution.

- Developed and implemented a new technique for concrete finishing, resulting in a smoother and more durable surface, reducing the need for additional postplacement treatments.

- Trained and mentored junior concrete placement operators, effectively transferring knowledge and best practices, improving overall team productivity and quality.

- Identified and resolved a potential equipment malfunction during a critical concrete pour, preventing delays and memastikan the structural integrity of the pour.

- Utilized advanced technology to monitor and control concrete consistency during placement, ensuring compliance with specifications and minimizing the risk of segregation.

Awards

- Received the Golden Trowel Award for exceptional concrete placement skills and maintaining highquality standards on multiple construction projects.

- Recognized with the Safety Excellence Award for consistently adhering to safety protocols and implementing innovative safety measures during concrete placement operations.

- Awarded the Precision Pumper Award for demonstrating exceptional accuracy and efficiency in operating concrete placement equipment, consistently achieving precise pours within tight tolerances.

- Recognized with the Project Excellence Award for contributing to the timely and successful completion of a complex infrastructure project involving extensive concrete placement operations.

Certificates

- American Concrete Institute (ACI) Certification

- Occupational Safety and Health Administration (OSHA) 30-Hour Safety Certification

- National Institute for Certification in Engineering Technologies (NICET) Level I Certification

- American Society of Concrete Contractors (ASCC) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Concrete Placement Equipment Operator

- Highlight your experience and skills in operating concrete placement equipment, including specific types of booms, pumps, and hoses.

- Showcase your knowledge of concrete placement techniques, mix design, and safety protocols to demonstrate your expertise.

- Quantify your accomplishments with specific metrics, such as the volume of concrete placed or the number of projects completed successfully.

- Tailor your resume to the specific requirements of the job you are applying for and highlight your relevant qualifications and experience.

Essential Experience Highlights for a Strong Concrete Placement Equipment Operator Resume

- Operate concrete placement booms with precision, ensuring accurate pouring and placement of concrete.

- Maintain and calibrate concrete placement equipment, including pumps, booms, and hoses, to ensure optimal performance.

- Collaborate with concrete finishers to determine proper placement and finishing techniques, ensuring high-quality results.

- Adhere to safety protocols related to concrete placement, including handling hazardous materials and operating heavy machinery.

- Monitor concrete delivery to ensure timely arrival and proper mix design, facilitating efficient concrete placement.

- Troubleshoot and resolve equipment malfunctions promptly, minimizing downtime and maintaining project progress.

- Utilize specialized tools and techniques for concrete placement, such as concrete testing and slump testing, to ensure proper concrete consistency and quality.

Frequently Asked Questions (FAQ’s) For Concrete Placement Equipment Operator

What are the key responsibilities of a Concrete Placement Equipment Operator?

The key responsibilities of a Concrete Placement Equipment Operator include operating concrete placement booms, pumps, and hoses; maintaining and calibrating equipment; collaborating with concrete finishers; following safety protocols; and troubleshooting equipment malfunctions.

What are the qualifications for becoming a Concrete Placement Equipment Operator?

To become a Concrete Placement Equipment Operator, you typically need an Associate’s Degree in Construction or a related field, as well as experience in operating heavy machinery and a strong understanding of concrete placement techniques and safety protocols.

What are the career prospects for Concrete Placement Equipment Operators?

Concrete Placement Equipment Operators can advance to positions such as Concrete Foreman, Construction Supervisor, or Project Manager. They may also specialize in operating specific types of equipment or in working on specialized projects, such as bridge or tunnel construction.

What are the challenges faced by Concrete Placement Equipment Operators?

Concrete Placement Equipment Operators may face challenges such as working in inclement weather, operating heavy machinery, and ensuring the safety of themselves and others on the job site.

What are the safety precautions that Concrete Placement Equipment Operators must follow?

Concrete Placement Equipment Operators must follow safety precautions such as wearing protective clothing and equipment, being aware of their surroundings, and following proper operating procedures to prevent accidents and injuries.

What are the skills required to be a successful Concrete Placement Equipment Operator?

Successful Concrete Placement Equipment Operators typically have strong mechanical skills, the ability to read and interpret blueprints, and the ability to work independently and as part of a team.