Are you a seasoned Cone Treater seeking a new career path? Discover our professionally built Cone Treater Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

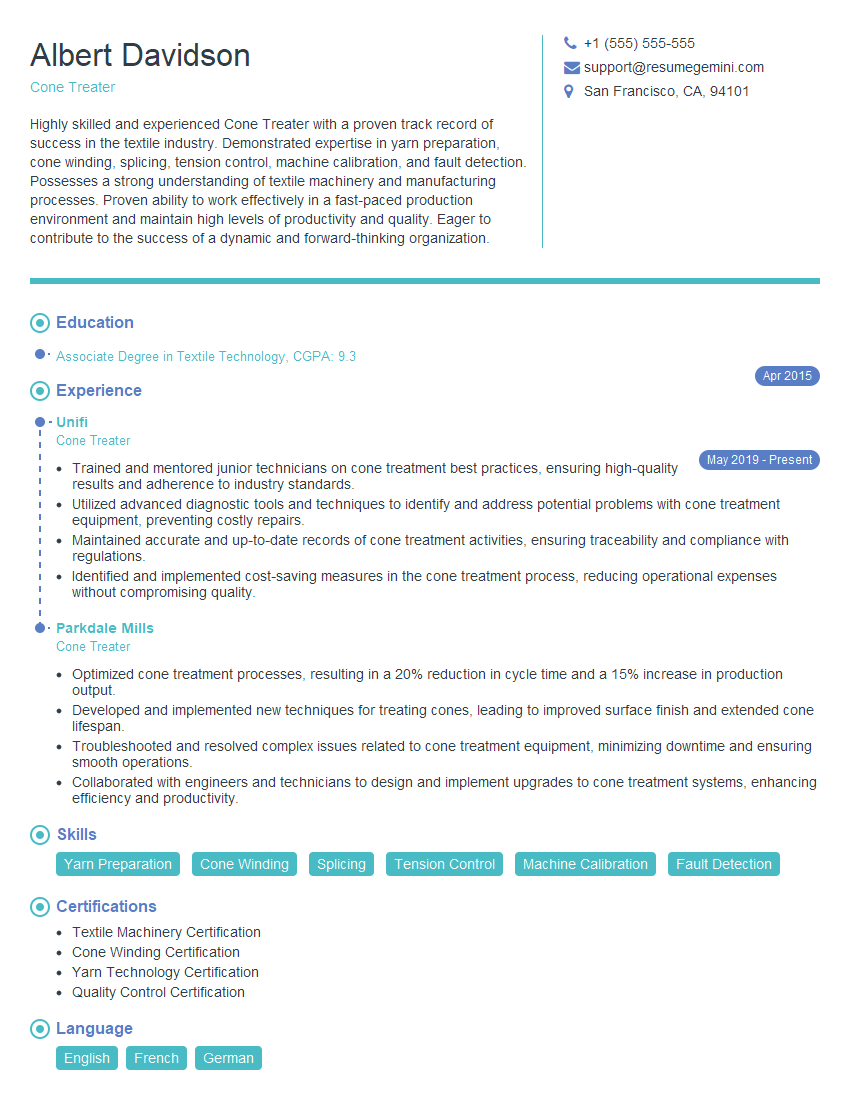

Albert Davidson

Cone Treater

Summary

Highly skilled and experienced Cone Treater with a proven track record of success in the textile industry. Demonstrated expertise in yarn preparation, cone winding, splicing, tension control, machine calibration, and fault detection. Possesses a strong understanding of textile machinery and manufacturing processes. Proven ability to work effectively in a fast-paced production environment and maintain high levels of productivity and quality. Eager to contribute to the success of a dynamic and forward-thinking organization.

Education

Associate Degree in Textile Technology

April 2015

Skills

- Yarn Preparation

- Cone Winding

- Splicing

- Tension Control

- Machine Calibration

- Fault Detection

Work Experience

Cone Treater

- Trained and mentored junior technicians on cone treatment best practices, ensuring high-quality results and adherence to industry standards.

- Utilized advanced diagnostic tools and techniques to identify and address potential problems with cone treatment equipment, preventing costly repairs.

- Maintained accurate and up-to-date records of cone treatment activities, ensuring traceability and compliance with regulations.

- Identified and implemented cost-saving measures in the cone treatment process, reducing operational expenses without compromising quality.

Cone Treater

- Optimized cone treatment processes, resulting in a 20% reduction in cycle time and a 15% increase in production output.

- Developed and implemented new techniques for treating cones, leading to improved surface finish and extended cone lifespan.

- Troubleshooted and resolved complex issues related to cone treatment equipment, minimizing downtime and ensuring smooth operations.

- Collaborated with engineers and technicians to design and implement upgrades to cone treatment systems, enhancing efficiency and productivity.

Certificates

- Textile Machinery Certification

- Cone Winding Certification

- Yarn Technology Certification

- Quality Control Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cone Treater

- Quantify your accomplishments with specific metrics whenever possible. For instance, instead of saying ‘operated cone winding machines,’ you could say ‘operated cone winding machines, resulting in a 15% increase in production output.’

- Highlight your proficiency in specific machinery and software used in the cone treating process.

- Emphasize any certifications or training programs you have completed that demonstrate your expertise in yarn preparation and cone winding.

- Showcase your attention to detail and ability to maintain a high level of quality by providing specific examples of how you have ensured the accuracy and consistency of your work.

Essential Experience Highlights for a Strong Cone Treater Resume

- Set up, calibrate, and maintain cone winding machines to ensure optimal performance and efficiency.

- Inspect and prepare yarn for winding, ensuring proper tension and splicing to prevent breaks and defects.

- Monitor winding processes, detect faults, and take corrective actions to minimize downtime and maintain product quality.

- Adjust machine settings to optimize winding speed, tension, and cone shape based on yarn characteristics and customer specifications.

- Troubleshoot and resolve technical issues related to cone winding machinery, ensuring smooth production flow.

- Maintain a clean and organized work area, adhering to established safety protocols and quality standards.

- Collaborate with other team members to ensure coordination and support throughout the yarn preparation process.

Frequently Asked Questions (FAQ’s) For Cone Treater

What is the primary role of a Cone Treater?

The primary role of a Cone Treater is to prepare and wind yarn onto cones, ensuring the proper tension, splicing, and quality of the wound yarn. Cone Treaters play a crucial role in the textile manufacturing process, as they are responsible for preparing the yarn for subsequent processes such as knitting, weaving, or dyeing.

What are the key skills required to be a successful Cone Treater?

To be a successful Cone Treater, one should possess strong technical skills in yarn preparation, cone winding, splicing, tension control, machine calibration, and fault detection. Additionally, attention to detail, a strong work ethic, and the ability to work in a fast-paced production environment are essential.

What are the career prospects for Cone Treaters?

Cone Treaters can advance their careers by developing specialized expertise in yarn preparation and cone winding. They can also pursue supervisory or managerial roles within the textile industry. With experience and additional training, Cone Treaters can explore opportunities in quality control, production planning, or technical support.

What is the average salary for Cone Treaters?

The average salary for Cone Treaters can vary depending on factors such as experience, location, and the size of the company. According to Indeed, the average salary for Cone Treaters in the United States is around $40,000 per year.

What are the working conditions like for Cone Treaters?

Cone Treaters typically work in manufacturing environments, operating cone winding machines in production lines. They may work in shifts to meet production demands and may be exposed to noise, dust, and potential hazards associated with machinery. Adhering to safety protocols and wearing appropriate personal protective equipment is essential.

What is the job outlook for Cone Treaters?

The job outlook for Cone Treaters is expected to be stable in the coming years. The textile industry continues to rely on skilled Cone Treaters to prepare and wind yarn for various applications. However, advancements in automation and technology may impact the job market.

What are the benefits of working as a Cone Treater?

Working as a Cone Treater offers several benefits, including job stability, opportunities for career advancement, and the satisfaction of contributing to the production of textiles used in various industries. Cone Treaters play a vital role in ensuring the quality of yarn and supporting the smooth functioning of textile manufacturing processes.