Are you a seasoned Control Equipment Electrician seeking a new career path? Discover our professionally built Control Equipment Electrician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

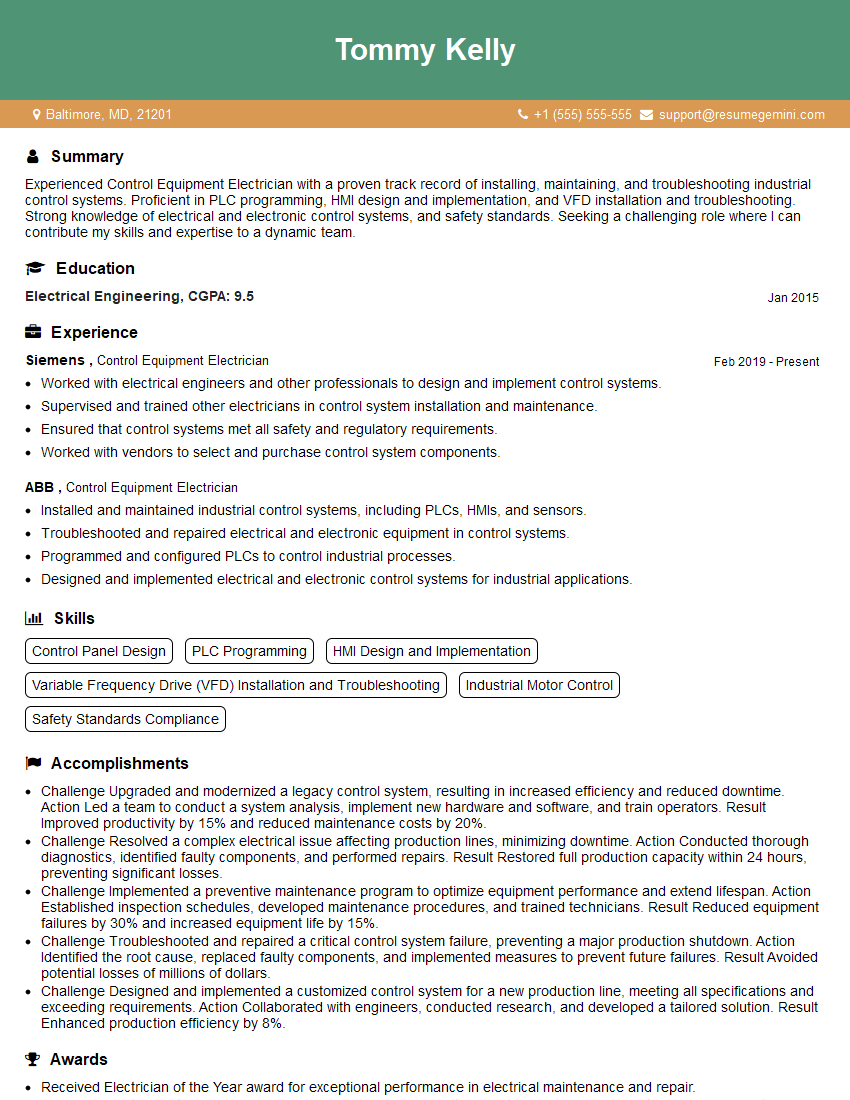

Tommy Kelly

Control Equipment Electrician

Summary

Experienced Control Equipment Electrician with a proven track record of installing, maintaining, and troubleshooting industrial control systems. Proficient in PLC programming, HMI design and implementation, and VFD installation and troubleshooting. Strong knowledge of electrical and electronic control systems, and safety standards. Seeking a challenging role where I can contribute my skills and expertise to a dynamic team.

Education

Electrical Engineering

January 2015

Skills

- Control Panel Design

- PLC Programming

- HMI Design and Implementation

- Variable Frequency Drive (VFD) Installation and Troubleshooting

- Industrial Motor Control

- Safety Standards Compliance

Work Experience

Control Equipment Electrician

- Worked with electrical engineers and other professionals to design and implement control systems.

- Supervised and trained other electricians in control system installation and maintenance.

- Ensured that control systems met all safety and regulatory requirements.

- Worked with vendors to select and purchase control system components.

Control Equipment Electrician

- Installed and maintained industrial control systems, including PLCs, HMIs, and sensors.

- Troubleshooted and repaired electrical and electronic equipment in control systems.

- Programmed and configured PLCs to control industrial processes.

- Designed and implemented electrical and electronic control systems for industrial applications.

Accomplishments

- Challenge Upgraded and modernized a legacy control system, resulting in increased efficiency and reduced downtime. Action Led a team to conduct a system analysis, implement new hardware and software, and train operators. Result Improved productivity by 15% and reduced maintenance costs by 20%.

- Challenge Resolved a complex electrical issue affecting production lines, minimizing downtime. Action Conducted thorough diagnostics, identified faulty components, and performed repairs. Result Restored full production capacity within 24 hours, preventing significant losses.

- Challenge Implemented a preventive maintenance program to optimize equipment performance and extend lifespan. Action Established inspection schedules, developed maintenance procedures, and trained technicians. Result Reduced equipment failures by 30% and increased equipment life by 15%.

- Challenge Troubleshooted and repaired a critical control system failure, preventing a major production shutdown. Action Identified the root cause, replaced faulty components, and implemented measures to prevent future failures. Result Avoided potential losses of millions of dollars.

- Challenge Designed and implemented a customized control system for a new production line, meeting all specifications and exceeding requirements. Action Collaborated with engineers, conducted research, and developed a tailored solution. Result Enhanced production efficiency by 8%.

Awards

- Received Electrician of the Year award for exceptional performance in electrical maintenance and repair.

- Recognized with Safety Excellence Award for implementing innovative safety measures and maintaining an accidentfree workplace.

- Honored with Innovation Award for developing a new method to calibrate control equipment, improving accuracy by 10%.

- Awarded Team Excellence Award for successfully leading a team in completing a complex electrical project on time and within budget.

Certificates

- Certified Control Equipment Electrician (CCEE)

- Certified Maintenance and Reliability Technician (CMRT)

- NFPA 70E Certification

- OSHA 30-Hour General Industry Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Control Equipment Electrician

- Highlight your experience with specific control system brands and models.

- Quantify your accomplishments with specific metrics whenever possible.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Control Equipment Electrician Resume

- Installed and maintained industrial control systems, including PLCs, HMIs, and sensors.

- Troubleshooted and repaired electrical and electronic equipment in control systems.

- Programmed and configured PLCs to control industrial processes.

- Designed and implemented electrical and electronic control systems for industrial applications.

- Worked with electrical engineers and other professionals to design and implement control systems.

- Supervised and trained other electricians in control system installation and maintenance.

- Ensured that control systems met all safety and regulatory requirements.

Frequently Asked Questions (FAQ’s) For Control Equipment Electrician

What is the role of a Control Equipment Electrician?

A Control Equipment Electrician installs, maintains, and repairs electrical and electronic control systems used in industrial and commercial applications.

What are the qualifications for a Control Equipment Electrician?

Most Control Equipment Electricians have a degree in electrical engineering or a related field, as well as several years of experience working with industrial control systems.

What are the key skills for a Control Equipment Electrician?

Key skills for a Control Equipment Electrician include PLC programming, HMI design and implementation, VFD installation and troubleshooting, and electrical and electronic control systems knowledge.

What is the job outlook for Control Equipment Electricians?

The job outlook for Control Equipment Electricians is expected to be good over the next few years, as there is a growing demand for qualified electricians to work on industrial control systems.

What are the salary expectations for Control Equipment Electricians?

The salary expectations for Control Equipment Electricians vary depending on experience, education, and location. According to Salary.com, the average salary for a Control Equipment Electrician in the United States is around $75,000 per year.

What are the benefits of working as a Control Equipment Electrician?

Benefits of working as a Control Equipment Electrician include the opportunity to work on challenging projects, the chance to learn about new technologies, and the potential for career advancement.

What are the challenges of working as a Control Equipment Electrician?

Challenges of working as a Control Equipment Electrician include the need to work in a variety of environments, the potential for exposure to hazardous materials, and the need to keep up with new technologies.

What is the best way to prepare for a career as a Control Equipment Electrician?

The best way to prepare for a career as a Control Equipment Electrician is to earn a degree in electrical engineering or a related field, and to gain experience working with industrial control systems.