Are you a seasoned Control Operator seeking a new career path? Discover our professionally built Control Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

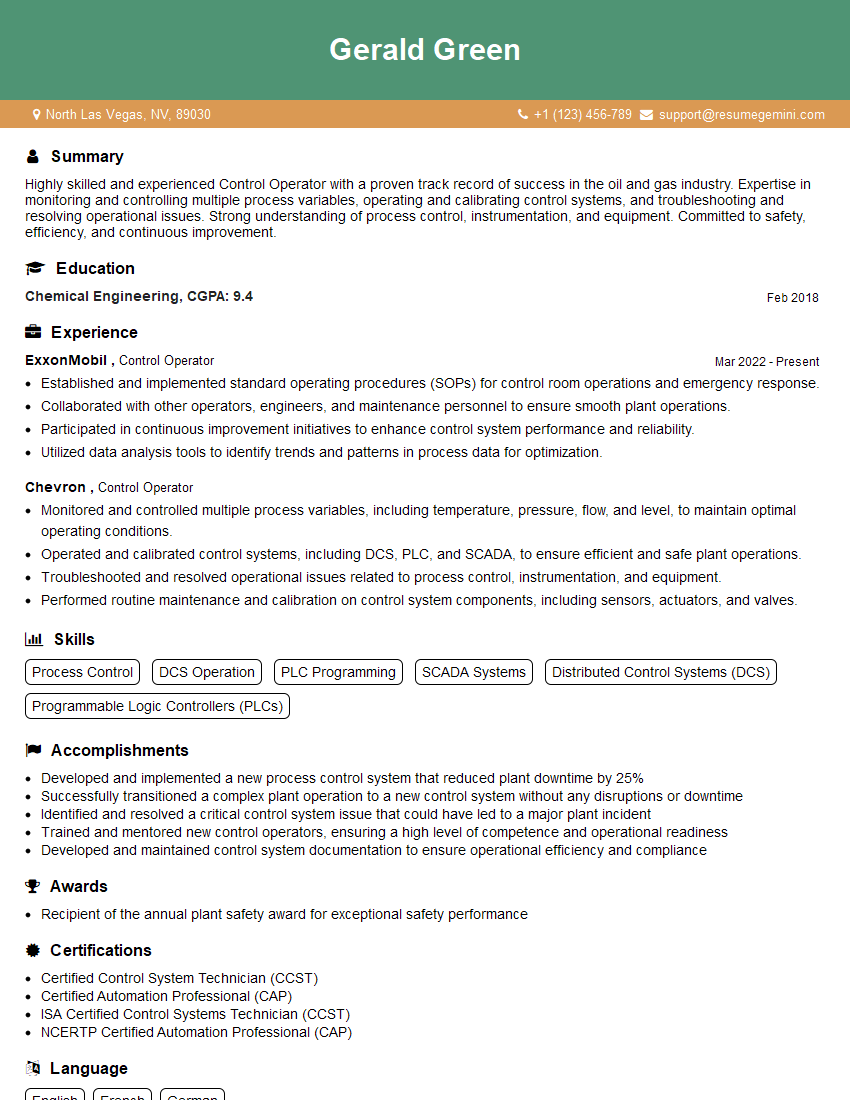

Gerald Green

Control Operator

Summary

Highly skilled and experienced Control Operator with a proven track record of success in the oil and gas industry. Expertise in monitoring and controlling multiple process variables, operating and calibrating control systems, and troubleshooting and resolving operational issues. Strong understanding of process control, instrumentation, and equipment. Committed to safety, efficiency, and continuous improvement.

Education

Chemical Engineering

February 2018

Skills

- Process Control

- DCS Operation

- PLC Programming

- SCADA Systems

- Distributed Control Systems (DCS)

- Programmable Logic Controllers (PLCs)

Work Experience

Control Operator

- Established and implemented standard operating procedures (SOPs) for control room operations and emergency response.

- Collaborated with other operators, engineers, and maintenance personnel to ensure smooth plant operations.

- Participated in continuous improvement initiatives to enhance control system performance and reliability.

- Utilized data analysis tools to identify trends and patterns in process data for optimization.

Control Operator

- Monitored and controlled multiple process variables, including temperature, pressure, flow, and level, to maintain optimal operating conditions.

- Operated and calibrated control systems, including DCS, PLC, and SCADA, to ensure efficient and safe plant operations.

- Troubleshooted and resolved operational issues related to process control, instrumentation, and equipment.

- Performed routine maintenance and calibration on control system components, including sensors, actuators, and valves.

Accomplishments

- Developed and implemented a new process control system that reduced plant downtime by 25%

- Successfully transitioned a complex plant operation to a new control system without any disruptions or downtime

- Identified and resolved a critical control system issue that could have led to a major plant incident

- Trained and mentored new control operators, ensuring a high level of competence and operational readiness

- Developed and maintained control system documentation to ensure operational efficiency and compliance

Awards

- Recipient of the annual plant safety award for exceptional safety performance

Certificates

- Certified Control System Technician (CCST)

- Certified Automation Professional (CAP)

- ISA Certified Control Systems Technician (CCST)

- NCERTP Certified Automation Professional (CAP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Control Operator

- Highlight your technical skills and experience in process control, DCS, PLC, and SCADA systems

- Showcase your ability to troubleshoot and resolve operational issues effectively

- Emphasize your commitment to safety and adherence to industry standards and regulations

- Quantify your accomplishments whenever possible to demonstrate the impact of your contributions

- Proofread your resume carefully for any errors or inconsistencies

Essential Experience Highlights for a Strong Control Operator Resume

- Monitored and controlled multiple process variables, including temperature, pressure, flow, and level, to maintain optimal operating conditions

- Operated and calibrated control systems, including DCS, PLC, and SCADA, to ensure efficient and safe plant operations

- Troubleshooted and resolved operational issues related to process control, instrumentation, and equipment

- Performed routine maintenance and calibration on control system components, including sensors, actuators, and valves

- Established and implemented standard operating procedures (SOPs) for control room operations and emergency response

- Collaborated with other operators, engineers, and maintenance personnel to ensure smooth plant operations

- Participated in continuous improvement initiatives to enhance control system performance and reliability

Frequently Asked Questions (FAQ’s) For Control Operator

What are the key skills required for a Control Operator?

The key skills required for a Control Operator include process control, DCS operation, PLC programming, SCADA systems, distributed control systems (DCS), programmable logic controllers (PLCs), and instrumentation.

What are the typical job responsibilities of a Control Operator?

The typical job responsibilities of a Control Operator include monitoring and controlling process variables, operating and calibrating control systems, troubleshooting and resolving operational issues, performing routine maintenance and calibration on control system components, and collaborating with other plant personnel.

What are the career prospects for a Control Operator?

The career prospects for a Control Operator are generally good, with opportunities for advancement to positions such as Senior Control Operator, Process Engineer, or Plant Manager.

What is the average salary for a Control Operator?

The average salary for a Control Operator varies depending on experience, location, and industry, but it typically ranges from $50,000 to $80,000 per year.

What are the educational requirements for a Control Operator?

The educational requirements for a Control Operator typically include a high school diploma or equivalent, although some employers may prefer candidates with an associate’s degree or higher in a related field such as chemical engineering or process control.

What are the certification requirements for a Control Operator?

There are no mandatory certification requirements for a Control Operator, but some employers may prefer candidates who have obtained certifications from organizations such as the International Society of Automation (ISA) or the National Institute for Certification in Engineering Technologies (NICET).

What are the safety considerations for a Control Operator?

Control Operators must be aware of the potential hazards associated with working in a plant environment, such as exposure to hazardous chemicals, high temperatures, and moving machinery. They must also be trained in emergency procedures and be able to respond quickly to any incidents that may occur.