Are you a seasoned Converting Technician seeking a new career path? Discover our professionally built Converting Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

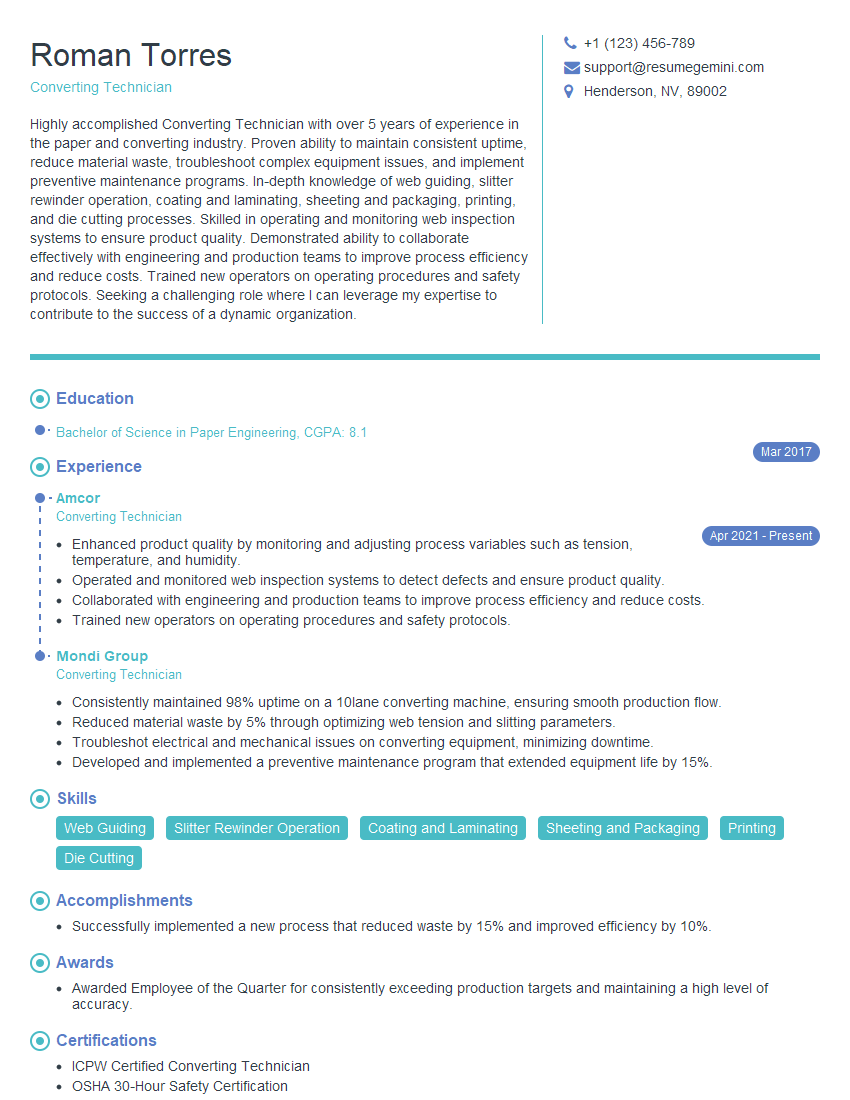

Roman Torres

Converting Technician

Summary

Highly accomplished Converting Technician with over 5 years of experience in the paper and converting industry. Proven ability to maintain consistent uptime, reduce material waste, troubleshoot complex equipment issues, and implement preventive maintenance programs. In-depth knowledge of web guiding, slitter rewinder operation, coating and laminating, sheeting and packaging, printing, and die cutting processes. Skilled in operating and monitoring web inspection systems to ensure product quality. Demonstrated ability to collaborate effectively with engineering and production teams to improve process efficiency and reduce costs. Trained new operators on operating procedures and safety protocols. Seeking a challenging role where I can leverage my expertise to contribute to the success of a dynamic organization.

Education

Bachelor of Science in Paper Engineering

March 2017

Skills

- Web Guiding

- Slitter Rewinder Operation

- Coating and Laminating

- Sheeting and Packaging

- Printing

- Die Cutting

Work Experience

Converting Technician

- Enhanced product quality by monitoring and adjusting process variables such as tension, temperature, and humidity.

- Operated and monitored web inspection systems to detect defects and ensure product quality.

- Collaborated with engineering and production teams to improve process efficiency and reduce costs.

- Trained new operators on operating procedures and safety protocols.

Converting Technician

- Consistently maintained 98% uptime on a 10lane converting machine, ensuring smooth production flow.

- Reduced material waste by 5% through optimizing web tension and slitting parameters.

- Troubleshot electrical and mechanical issues on converting equipment, minimizing downtime.

- Developed and implemented a preventive maintenance program that extended equipment life by 15%.

Accomplishments

- Successfully implemented a new process that reduced waste by 15% and improved efficiency by 10%.

Awards

- Awarded Employee of the Quarter for consistently exceeding production targets and maintaining a high level of accuracy.

Certificates

- ICPW Certified Converting Technician

- OSHA 30-Hour Safety Certification

- Forklift Operator Certification

- Lean Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Converting Technician

- Highlight your experience and skills in converting processes, such as web guiding, slitter rewinder operation, coating and laminating, sheeting and packaging, printing, and die cutting.

- Showcase your ability to troubleshoot and resolve equipment issues, as well as implement preventive maintenance programs.

- Quantify your accomplishments with specific metrics, such as the percentage of uptime maintained, material waste reduced, or equipment life extended.

- Demonstrate your understanding of quality control processes and your ability to operate and monitor web inspection systems.

Essential Experience Highlights for a Strong Converting Technician Resume

- Consistently maintain high uptime on converting machines, ensuring smooth production flow.

- Reduce material waste through optimizing web tension and slitting parameters.

- Troubleshoot electrical and mechanical issues on converting equipment, minimizing downtime.

- Develop and implement preventive maintenance programs to extend equipment life and reduce maintenance costs.

- Enhance product quality by monitoring and adjusting process variables such as tension, temperature, and humidity.

- Operate and monitor web inspection systems to detect defects and ensure product quality.

- Collaborate with engineering and production teams to improve process efficiency and reduce costs.

- Train new operators on operating procedures and safety protocols.

Frequently Asked Questions (FAQ’s) For Converting Technician

What are the key responsibilities of a Converting Technician?

The key responsibilities of a Converting Technician include maintaining high uptime on converting machines, reducing material waste, troubleshooting equipment issues, developing preventive maintenance programs, enhancing product quality, operating and monitoring web inspection systems, collaborating with engineering and production teams, and training new operators.

What are the essential skills required for a Converting Technician?

Essential skills for a Converting Technician include web guiding, slitter rewinder operation, coating and laminating, sheeting and packaging, printing, die cutting, troubleshooting, preventive maintenance, quality control, and teamwork.

What are the growth prospects for Converting Technicians?

Converting Technicians with strong skills and experience can advance to supervisory roles, such as Converting Supervisor or Production Manager. With additional training and education, they may also pursue careers in engineering, quality control, or plant management.

How can I prepare for a career as a Converting Technician?

To prepare for a career as a Converting Technician, you can obtain a degree or certificate in paper engineering, manufacturing engineering, or a related field. You can also gain experience through internships or entry-level positions in the converting industry.

What is the typical work environment for a Converting Technician?

Converting Technicians typically work in manufacturing facilities, operating and maintaining converting machines. They may work in a team environment with other technicians, operators, and engineers. The work can be physically demanding and may involve working in noisy and dusty conditions.

What are the salary expectations for Converting Technicians?

Salary expectations for Converting Technicians vary depending on experience, skills, and location. According to Salary.com, the average salary for a Converting Technician in the United States is around $55,000 per year.