Are you a seasoned Copper Etcher seeking a new career path? Discover our professionally built Copper Etcher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

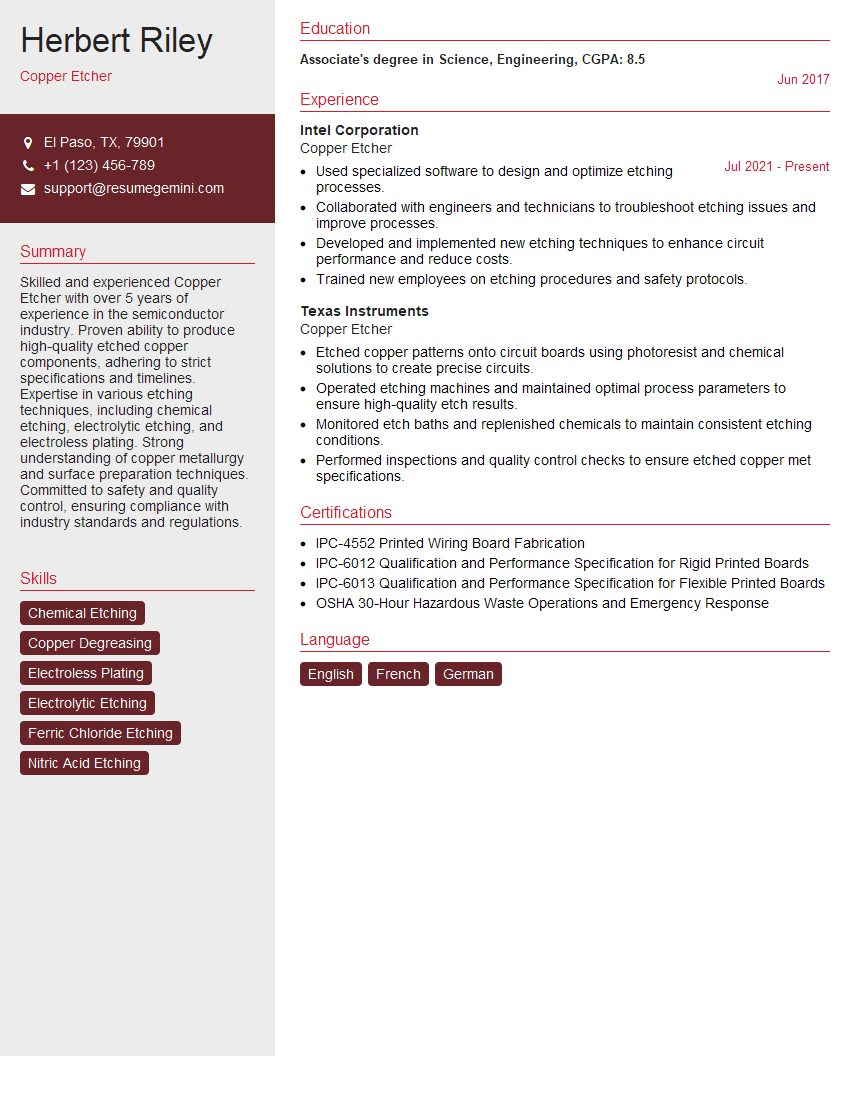

Herbert Riley

Copper Etcher

Summary

Skilled and experienced Copper Etcher with over 5 years of experience in the semiconductor industry. Proven ability to produce high-quality etched copper components, adhering to strict specifications and timelines. Expertise in various etching techniques, including chemical etching, electrolytic etching, and electroless plating. Strong understanding of copper metallurgy and surface preparation techniques. Committed to safety and quality control, ensuring compliance with industry standards and regulations.

Education

Associate’s degree in Science, Engineering

June 2017

Skills

- Chemical Etching

- Copper Degreasing

- Electroless Plating

- Electrolytic Etching

- Ferric Chloride Etching

- Nitric Acid Etching

Work Experience

Copper Etcher

- Used specialized software to design and optimize etching processes.

- Collaborated with engineers and technicians to troubleshoot etching issues and improve processes.

- Developed and implemented new etching techniques to enhance circuit performance and reduce costs.

- Trained new employees on etching procedures and safety protocols.

Copper Etcher

- Etched copper patterns onto circuit boards using photoresist and chemical solutions to create precise circuits.

- Operated etching machines and maintained optimal process parameters to ensure high-quality etch results.

- Monitored etch baths and replenished chemicals to maintain consistent etching conditions.

- Performed inspections and quality control checks to ensure etched copper met specifications.

Certificates

- IPC-4552 Printed Wiring Board Fabrication

- IPC-6012 Qualification and Performance Specification for Rigid Printed Boards

- IPC-6013 Qualification and Performance Specification for Flexible Printed Boards

- OSHA 30-Hour Hazardous Waste Operations and Emergency Response

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Copper Etcher

- Highlight your expertise in different copper etching techniques and your understanding of copper metallurgy.

- Showcase your ability to work in a fast-paced environment and meet tight deadlines.

- Emphasize your commitment to quality control and safety compliance.

- Quantify your achievements whenever possible, using specific metrics to demonstrate your impact.

Essential Experience Highlights for a Strong Copper Etcher Resume

- Perform copper etching processes, including chemical etching, electrolytic etching, and electroless plating

- Degrease and prepare copper surfaces to ensure proper adhesion of etchants

- Control etching parameters, such as temperature, concentration, and duration, to achieve desired results

- Monitor etching progress and make adjustments as needed to maintain quality standards

- Inspect etched components for defects and ensure compliance with specifications

- Maintain and calibrate etching equipment to ensure optimal performance

- Follow safety protocols and adhere to environmental regulations related to etching processes

Frequently Asked Questions (FAQ’s) For Copper Etcher

What is copper etching?

Copper etching is a subtractive manufacturing process used to create patterns in copper by selectively removing material from the surface.

What are the different types of copper etching?

There are several types of copper etching, including chemical etching, electrolytic etching, and electroless plating.

What are the applications of copper etching?

Copper etching is widely used in the semiconductor industry to create electronic circuits, as well as in the manufacturing of printed circuit boards (PCBs) and other electronic components.

What are the safety precautions to consider when copper etching?

Copper etching involves the use of hazardous chemicals, so it is important to follow proper safety protocols, including wearing protective gear, working in a well-ventilated area, and disposing of chemicals properly.

What are the career opportunities for a Copper Etcher?

Copper Etchers can find opportunities in various industries, including the semiconductor, electronics, and manufacturing sectors. With experience and additional training, they can advance to supervisory or management roles.

What is the average salary for a Copper Etcher?

The average salary for a Copper Etcher can vary depending on experience, location, and industry. According to Indeed, the average salary for a Copper Etcher in the United States is around $45,000 per year.