Are you a seasoned Core Blower seeking a new career path? Discover our professionally built Core Blower Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

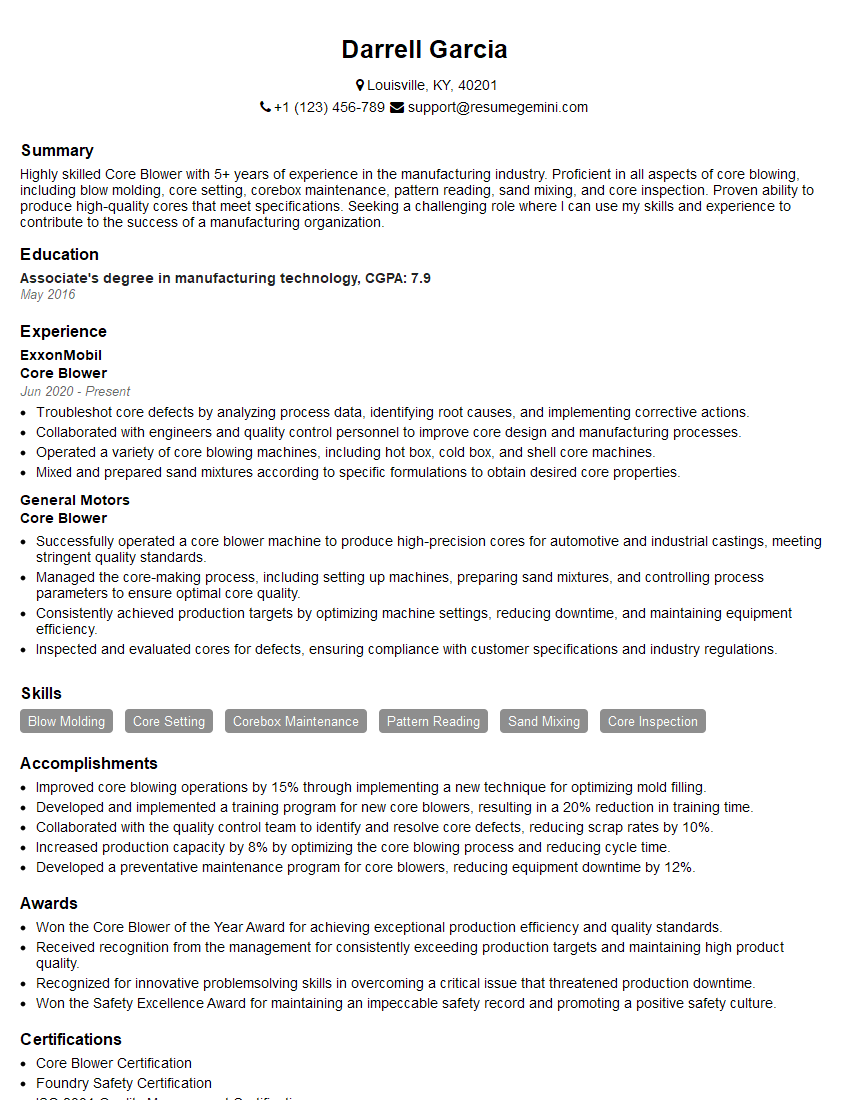

Darrell Garcia

Core Blower

Summary

Highly skilled Core Blower with 5+ years of experience in the manufacturing industry. Proficient in all aspects of core blowing, including blow molding, core setting, corebox maintenance, pattern reading, sand mixing, and core inspection. Proven ability to produce high-quality cores that meet specifications. Seeking a challenging role where I can use my skills and experience to contribute to the success of a manufacturing organization.

Education

Associate’s degree in manufacturing technology

May 2016

Skills

- Blow Molding

- Core Setting

- Corebox Maintenance

- Pattern Reading

- Sand Mixing

- Core Inspection

Work Experience

Core Blower

- Troubleshot core defects by analyzing process data, identifying root causes, and implementing corrective actions.

- Collaborated with engineers and quality control personnel to improve core design and manufacturing processes.

- Operated a variety of core blowing machines, including hot box, cold box, and shell core machines.

- Mixed and prepared sand mixtures according to specific formulations to obtain desired core properties.

Core Blower

- Successfully operated a core blower machine to produce high-precision cores for automotive and industrial castings, meeting stringent quality standards.

- Managed the core-making process, including setting up machines, preparing sand mixtures, and controlling process parameters to ensure optimal core quality.

- Consistently achieved production targets by optimizing machine settings, reducing downtime, and maintaining equipment efficiency.

- Inspected and evaluated cores for defects, ensuring compliance with customer specifications and industry regulations.

Accomplishments

- Improved core blowing operations by 15% through implementing a new technique for optimizing mold filling.

- Developed and implemented a training program for new core blowers, resulting in a 20% reduction in training time.

- Collaborated with the quality control team to identify and resolve core defects, reducing scrap rates by 10%.

- Increased production capacity by 8% by optimizing the core blowing process and reducing cycle time.

- Developed a preventative maintenance program for core blowers, reducing equipment downtime by 12%.

Awards

- Won the Core Blower of the Year Award for achieving exceptional production efficiency and quality standards.

- Received recognition from the management for consistently exceeding production targets and maintaining high product quality.

- Recognized for innovative problemsolving skills in overcoming a critical issue that threatened production downtime.

- Won the Safety Excellence Award for maintaining an impeccable safety record and promoting a positive safety culture.

Certificates

- Core Blower Certification

- Foundry Safety Certification

- ISO 9001 Quality Management Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Core Blower

- Highlight your experience and skills in core blowing, including any certifications or training.

- Showcase your knowledge of core blowing machines and equipment.

- Emphasize your attention to detail and quality control.

- Provide examples of your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Core Blower Resume

- Set up and operate core blowing machines to produce sand cores for metal castings.

- Mix and prepare sand according to specifications to create the cores.

- Inspect cores to ensure they meet quality standards.

- Maintain and repair core blowing machines and equipment.

- Provide technical support to other core makers and operators.

- Train new employees on core blowing procedures.

- Maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Core Blower

What is a core blower?

A core blower is a machine that uses compressed air to blow sand into a core box, creating a sand core that is used in metal casting.

What are the different types of core blowing machines?

There are two main types of core blowing machines: vertical core blowers and horizontal core blowers.

What are the different types of sand used in core blowing?

The most common type of sand used in core blowing is silica sand, but other types of sand, such as olivine sand and zircon sand, can also be used.

What are the different types of core boxes used in core blowing?

Core boxes are typically made of metal or wood and come in a variety of shapes and sizes.

What are the different types of cores produced by core blowing?

Cores can be classified by their shape, size, and purpose.

What are the different industries that use core blowing?

Core blowing is used in a variety of industries, including the automotive, aerospace, and construction industries.

What are the safety precautions that should be taken when operating a core blowing machine?

Safety precautions include wearing appropriate safety gear, such as safety glasses, gloves, and earplugs, and keeping the work area clean and free of tripping hazards.

What are the career opportunities for core blowers?

Core blowers can advance to positions such as core room supervisor, quality control inspector, or production manager.