Are you a seasoned Core Extruder seeking a new career path? Discover our professionally built Core Extruder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

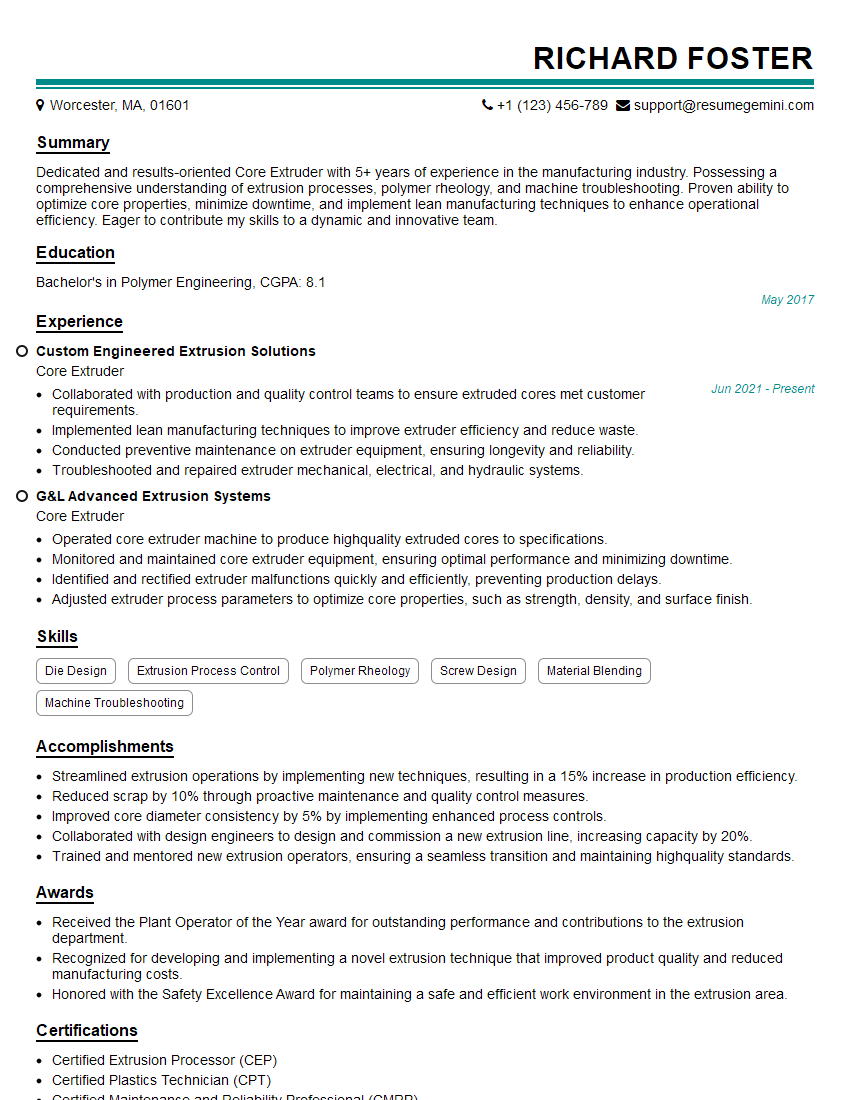

Richard Foster

Core Extruder

Summary

Dedicated and results-oriented Core Extruder with 5+ years of experience in the manufacturing industry. Possessing a comprehensive understanding of extrusion processes, polymer rheology, and machine troubleshooting. Proven ability to optimize core properties, minimize downtime, and implement lean manufacturing techniques to enhance operational efficiency. Eager to contribute my skills to a dynamic and innovative team.

Education

Bachelor’s in Polymer Engineering

May 2017

Skills

- Die Design

- Extrusion Process Control

- Polymer Rheology

- Screw Design

- Material Blending

- Machine Troubleshooting

Work Experience

Core Extruder

- Collaborated with production and quality control teams to ensure extruded cores met customer requirements.

- Implemented lean manufacturing techniques to improve extruder efficiency and reduce waste.

- Conducted preventive maintenance on extruder equipment, ensuring longevity and reliability.

- Troubleshooted and repaired extruder mechanical, electrical, and hydraulic systems.

Core Extruder

- Operated core extruder machine to produce highquality extruded cores to specifications.

- Monitored and maintained core extruder equipment, ensuring optimal performance and minimizing downtime.

- Identified and rectified extruder malfunctions quickly and efficiently, preventing production delays.

- Adjusted extruder process parameters to optimize core properties, such as strength, density, and surface finish.

Accomplishments

- Streamlined extrusion operations by implementing new techniques, resulting in a 15% increase in production efficiency.

- Reduced scrap by 10% through proactive maintenance and quality control measures.

- Improved core diameter consistency by 5% by implementing enhanced process controls.

- Collaborated with design engineers to design and commission a new extrusion line, increasing capacity by 20%.

- Trained and mentored new extrusion operators, ensuring a seamless transition and maintaining highquality standards.

Awards

- Received the Plant Operator of the Year award for outstanding performance and contributions to the extrusion department.

- Recognized for developing and implementing a novel extrusion technique that improved product quality and reduced manufacturing costs.

- Honored with the Safety Excellence Award for maintaining a safe and efficient work environment in the extrusion area.

Certificates

- Certified Extrusion Processor (CEP)

- Certified Plastics Technician (CPT)

- Certified Maintenance and Reliability Professional (CMRP)

- Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Core Extruder

- Highlight your technical proficiency in extrusion process control, polymer rheology, and screw design.

- Showcase your problem-solving skills and ability to troubleshoot and repair extruder systems.

- Quantify your accomplishments whenever possible, providing specific metrics to demonstrate your impact on productivity and efficiency.

- Tailor your resume to each job application, emphasizing the skills and experience most relevant to the specific role.

- Proofread your resume carefully before submitting it to ensure there are no errors.

Essential Experience Highlights for a Strong Core Extruder Resume

- Operated core extruder machines to manufacture high-quality extruded cores adhering to specifications.

- Monitored and maintained core extruder equipment to ensure optimal performance and minimize downtime.

- Identified and rectified extruder malfunctions promptly and efficiently, preventing production delays.

- Adjusted extruder process parameters to optimize core properties, including strength, density, and surface finish.

- Collaborated with production and quality control teams to ensure extruded cores met customer requirements.

Frequently Asked Questions (FAQ’s) For Core Extruder

What is the primary role of a Core Extruder?

The primary role of a Core Extruder is to operate and maintain core extruder machinery to produce high-quality extruded cores used in various industrial applications.

What skills are essential for a successful Core Extruder?

Essential skills for a Core Extruder include a strong understanding of extrusion processes, polymer rheology, screw design, and machine troubleshooting.

How can I improve my chances of getting hired as a Core Extruder?

To improve your chances of getting hired as a Core Extruder, consider obtaining a Bachelor’s degree in Polymer Engineering or a related field, gaining practical experience through internships or projects, and developing strong problem-solving and analytical skills.

What are the common challenges faced by Core Extruders?

Common challenges faced by Core Extruders include maintaining optimal extruder performance, troubleshooting and repairing malfunctions, and ensuring the quality of extruded cores meets customer specifications.

What is the career progression path for a Core Extruder?

The career progression path for a Core Extruder typically involves advancement to roles such as Extrusion Supervisor, Production Manager, or Research and Development Engineer.

What is the average salary for a Core Extruder?

The average salary for a Core Extruder can vary depending on experience, location, and industry, but typically falls within the range of $50,000 to $80,000 per year.