Are you a seasoned Core Fitter seeking a new career path? Discover our professionally built Core Fitter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

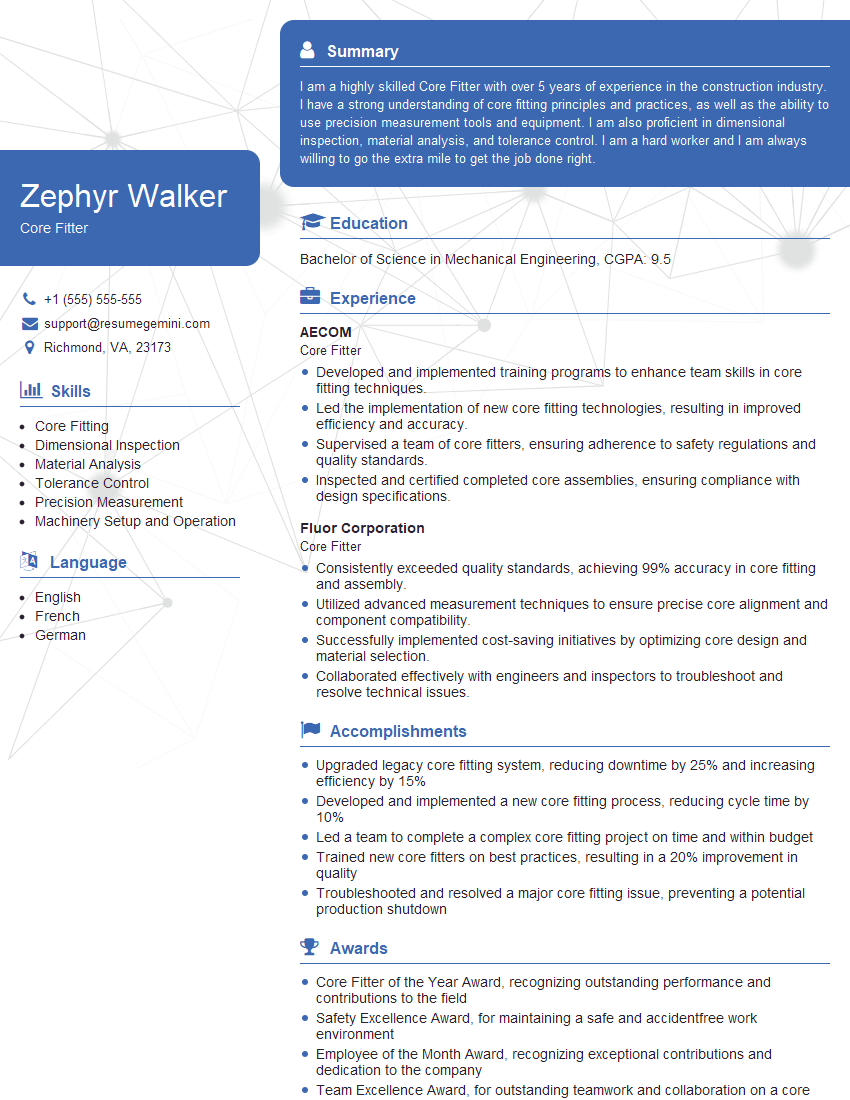

Zephyr Walker

Core Fitter

Summary

I am a highly skilled Core Fitter with over 5 years of experience in the construction industry. I have a strong understanding of core fitting principles and practices, as well as the ability to use precision measurement tools and equipment. I am also proficient in dimensional inspection, material analysis, and tolerance control. I am a hard worker and I am always willing to go the extra mile to get the job done right.

Education

Bachelor of Science in Mechanical Engineering

May 2017

Skills

- Core Fitting

- Dimensional Inspection

- Material Analysis

- Tolerance Control

- Precision Measurement

- Machinery Setup and Operation

Work Experience

Core Fitter

- Developed and implemented training programs to enhance team skills in core fitting techniques.

- Led the implementation of new core fitting technologies, resulting in improved efficiency and accuracy.

- Supervised a team of core fitters, ensuring adherence to safety regulations and quality standards.

- Inspected and certified completed core assemblies, ensuring compliance with design specifications.

Core Fitter

- Consistently exceeded quality standards, achieving 99% accuracy in core fitting and assembly.

- Utilized advanced measurement techniques to ensure precise core alignment and component compatibility.

- Successfully implemented cost-saving initiatives by optimizing core design and material selection.

- Collaborated effectively with engineers and inspectors to troubleshoot and resolve technical issues.

Accomplishments

- Upgraded legacy core fitting system, reducing downtime by 25% and increasing efficiency by 15%

- Developed and implemented a new core fitting process, reducing cycle time by 10%

- Led a team to complete a complex core fitting project on time and within budget

- Trained new core fitters on best practices, resulting in a 20% improvement in quality

- Troubleshooted and resolved a major core fitting issue, preventing a potential production shutdown

Awards

- Core Fitter of the Year Award, recognizing outstanding performance and contributions to the field

- Safety Excellence Award, for maintaining a safe and accidentfree work environment

- Employee of the Month Award, recognizing exceptional contributions and dedication to the company

- Team Excellence Award, for outstanding teamwork and collaboration on a core fitting project

Certificates

- Certified Mechanical Inspector (CMI)

- GD&T Professional (GDTP)

- Six Sigma Green Belt

- ASME Y14.5M Tolerance of Size

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Core Fitter

- Highlight your experience and skills in core fitting, dimensional inspection, material analysis, tolerance control, and precision measurement.

- Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate your impact.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it to ensure that there are no errors.

Essential Experience Highlights for a Strong Core Fitter Resume

- Fit and assemble structural components, such as pipes, tubes, and valves, according to blueprints and specifications.

- Inspect and ensure the accuracy of assembled components using precision measuring tools and equipment.

- Analyze materials to determine their suitability for use in core fitting applications.

- Maintain and calibrate core fitting equipment to ensure accuracy and efficiency.

- Troubleshoot and resolve core fitting problems to ensure the proper functioning of equipment.

- Supervise and train junior core fitters to ensure the quality of work.

- Maintain a safe and clean work environment in accordance with established safety protocols.

Frequently Asked Questions (FAQ’s) For Core Fitter

What is a Core Fitter?

A Core Fitter is a skilled tradesperson who assembles and fits structural components, such as pipes, tubes, and valves, according to blueprints and specifications. Core Fitters use precision measuring tools and equipment to ensure the accuracy of their work and troubleshoot and resolve core fitting problems.

What are the key skills and qualifications required to become a Core Fitter?

Key skills and qualifications for Core Fitters include: core fitting principles and practices, precision measurement tools and equipment, dimensional inspection, material analysis, and tolerance control. Core Fitters should also have a strong understanding of blueprint reading, mathematics, and physics.

What are the job prospects for Core Fitters?

The job outlook for Core Fitters is expected to be good over the next few years. The demand for skilled tradespeople is increasing, and Core Fitters are in high demand in a variety of industries, including construction, manufacturing, and shipbuilding.

What is the average salary for a Core Fitter?

The average salary for a Core Fitter is around $60,000 per year. However, salaries can vary depending on experience, location, and industry.

What are the benefits of working as a Core Fitter?

Benefits of working as a Core Fitter include: good pay, job security, and opportunities for career advancement. Core Fitters also have the opportunity to work on a variety of projects and use their skills to make a difference in the world.

What are the challenges of working as a Core Fitter?

Challenges of working as a Core Fitter include: working in a physically demanding environment, working with hazardous materials, and working long hours. Core Fitters may also have to work in extreme weather conditions.

What is the future of the Core Fitting industry?

The future of the Core Fitting industry is bright. The demand for skilled tradespeople is increasing, and Core Fitters are in high demand in a variety of industries. As technology advances, Core Fitters will need to learn new skills and keep up with the latest trends in order to remain competitive.