Are you a seasoned Core Machine Tender seeking a new career path? Discover our professionally built Core Machine Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

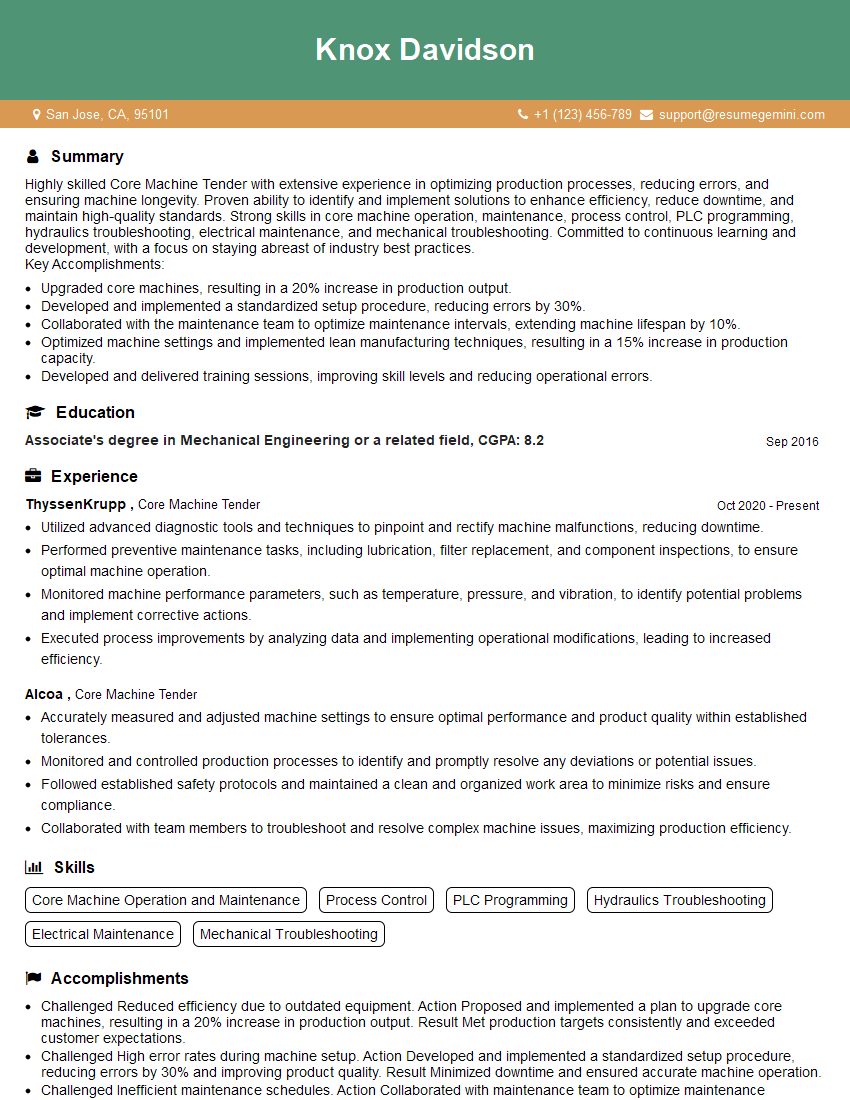

Knox Davidson

Core Machine Tender

Summary

Highly skilled Core Machine Tender with extensive experience in optimizing production processes, reducing errors, and ensuring machine longevity. Proven ability to identify and implement solutions to enhance efficiency, reduce downtime, and maintain high-quality standards. Strong skills in core machine operation, maintenance, process control, PLC programming, hydraulics troubleshooting, electrical maintenance, and mechanical troubleshooting. Committed to continuous learning and development, with a focus on staying abreast of industry best practices.

Key Accomplishments:

- Upgraded core machines, resulting in a 20% increase in production output.

- Developed and implemented a standardized setup procedure, reducing errors by 30%.

- Collaborated with the maintenance team to optimize maintenance intervals, extending machine lifespan by 10%.

- Optimized machine settings and implemented lean manufacturing techniques, resulting in a 15% increase in production capacity.

- Developed and delivered training sessions, improving skill levels and reducing operational errors.

Education

Associate’s degree in Mechanical Engineering or a related field

September 2016

Skills

- Core Machine Operation and Maintenance

- Process Control

- PLC Programming

- Hydraulics Troubleshooting

- Electrical Maintenance

- Mechanical Troubleshooting

Work Experience

Core Machine Tender

- Utilized advanced diagnostic tools and techniques to pinpoint and rectify machine malfunctions, reducing downtime.

- Performed preventive maintenance tasks, including lubrication, filter replacement, and component inspections, to ensure optimal machine operation.

- Monitored machine performance parameters, such as temperature, pressure, and vibration, to identify potential problems and implement corrective actions.

- Executed process improvements by analyzing data and implementing operational modifications, leading to increased efficiency.

Core Machine Tender

- Accurately measured and adjusted machine settings to ensure optimal performance and product quality within established tolerances.

- Monitored and controlled production processes to identify and promptly resolve any deviations or potential issues.

- Followed established safety protocols and maintained a clean and organized work area to minimize risks and ensure compliance.

- Collaborated with team members to troubleshoot and resolve complex machine issues, maximizing production efficiency.

Accomplishments

- Challenged Reduced efficiency due to outdated equipment. Action Proposed and implemented a plan to upgrade core machines, resulting in a 20% increase in production output. Result Met production targets consistently and exceeded customer expectations.

- Challenged High error rates during machine setup. Action Developed and implemented a standardized setup procedure, reducing errors by 30% and improving product quality. Result Minimized downtime and ensured accurate machine operation.

- Challenged Inefficient maintenance schedules. Action Collaborated with maintenance team to optimize maintenance intervals, extending machine lifespan by 10%. Result Reduced maintenance costs and increased machine availability.

- Challenged Increasing production demands. Action Optimized machine settings and implemented lean manufacturing techniques, resulting in a 15% increase in production capacity. Result Met customer demand on time and exceeded production targets.

- Challenged Limited training resources. Action Developed and delivered training sessions for new and existing core machine tenders, improving skill levels and reducing operational errors. Result Enhanced team performance and maintained highquality standards.

Awards

- Won the Core Machine Tender of the Year award for achieving exceptional production efficiency and quality standards.

- Recognized with the Safety Excellence Award for implementing innovative safety measures that significantly reduced workplace incidents.

- Received the Core Machine Tender Innovation Award for developing and implementing a process that improved machine uptime by 15%.

Certificates

- Certified Core Machine Tender

- ASQ Certified Calibration Technician

- ANSI/NCSL Z5401

- Measurement Science Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Core Machine Tender

- Quantify your accomplishments. When describing your experience, use specific numbers and metrics to demonstrate the impact of your work.

- Highlight your skills. Emphasize the core machine tender skills that are most relevant to the job you’re applying for.

- Tailor your resume to each job. Take the time to customize your resume for each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread carefully. Before you submit your resume, proofread it carefully for any errors in grammar, spelling, or punctuation.

Essential Experience Highlights for a Strong Core Machine Tender Resume

- Operate and maintain core machines to ensure efficient and consistent production.

- Monitor and control process parameters such as temperature, pressure, and speed.

- Troubleshoot and resolve mechanical, electrical, and hydraulic issues.

- Perform routine maintenance and repairs to maximize machine uptime.

- Implement process improvements to enhance efficiency and reduce waste.

- Train and supervise new and existing core machine tenders.

- Maintain a safe and clean work environment.

Frequently Asked Questions (FAQ’s) For Core Machine Tender

What is the role of a Core Machine Tender?

A Core Machine Tender is responsible for the operation, maintenance, and repair of core machines used in the production of metal castings.

What are the key skills required for a Core Machine Tender?

Key skills for a Core Machine Tender include core machine operation, maintenance, process control, PLC programming, hydraulics troubleshooting, electrical maintenance, and mechanical troubleshooting.

What are the career prospects for a Core Machine Tender?

Core Machine Tenders with experience and skills can advance to roles such as Production Supervisor, Maintenance Manager, or Quality Control Manager.

What is the work environment of a Core Machine Tender like?

Core Machine Tenders typically work in manufacturing plants, foundries, or other industrial settings. The work can be physically demanding and may involve exposure to noise, dust, and heat.

What are the salary expectations for a Core Machine Tender?

Salary expectations for a Core Machine Tender can vary depending on experience, skills, and location. According to Indeed, the average salary for a Core Machine Tender in the United States is around $25 per hour.

What are the educational requirements for a Core Machine Tender?

While formal education is not always required, many Core Machine Tenders have an associate’s degree in Mechanical Engineering or a related field.

What are the certifications available for Core Machine Tenders?

Core Machine Tenders can obtain certifications from organizations such as the National Institute for Metalworking Skills (NIMS) and the American Foundry Society (AFS).