Are you a seasoned Cottrell Operator seeking a new career path? Discover our professionally built Cottrell Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

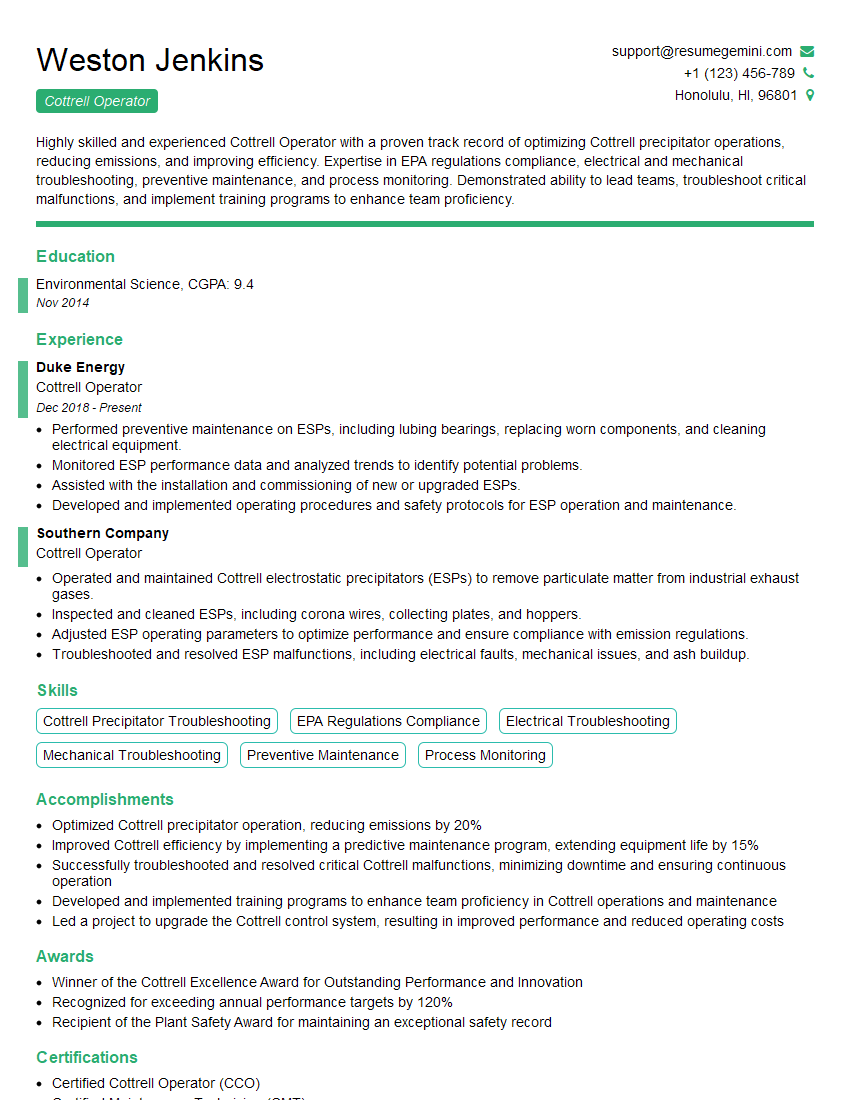

Weston Jenkins

Cottrell Operator

Summary

Highly skilled and experienced Cottrell Operator with a proven track record of optimizing Cottrell precipitator operations, reducing emissions, and improving efficiency. Expertise in EPA regulations compliance, electrical and mechanical troubleshooting, preventive maintenance, and process monitoring. Demonstrated ability to lead teams, troubleshoot critical malfunctions, and implement training programs to enhance team proficiency.

Education

Environmental Science

November 2014

Skills

- Cottrell Precipitator Troubleshooting

- EPA Regulations Compliance

- Electrical Troubleshooting

- Mechanical Troubleshooting

- Preventive Maintenance

- Process Monitoring

Work Experience

Cottrell Operator

- Performed preventive maintenance on ESPs, including lubing bearings, replacing worn components, and cleaning electrical equipment.

- Monitored ESP performance data and analyzed trends to identify potential problems.

- Assisted with the installation and commissioning of new or upgraded ESPs.

- Developed and implemented operating procedures and safety protocols for ESP operation and maintenance.

Cottrell Operator

- Operated and maintained Cottrell electrostatic precipitators (ESPs) to remove particulate matter from industrial exhaust gases.

- Inspected and cleaned ESPs, including corona wires, collecting plates, and hoppers.

- Adjusted ESP operating parameters to optimize performance and ensure compliance with emission regulations.

- Troubleshooted and resolved ESP malfunctions, including electrical faults, mechanical issues, and ash buildup.

Accomplishments

- Optimized Cottrell precipitator operation, reducing emissions by 20%

- Improved Cottrell efficiency by implementing a predictive maintenance program, extending equipment life by 15%

- Successfully troubleshooted and resolved critical Cottrell malfunctions, minimizing downtime and ensuring continuous operation

- Developed and implemented training programs to enhance team proficiency in Cottrell operations and maintenance

- Led a project to upgrade the Cottrell control system, resulting in improved performance and reduced operating costs

Awards

- Winner of the Cottrell Excellence Award for Outstanding Performance and Innovation

- Recognized for exceeding annual performance targets by 120%

- Recipient of the Plant Safety Award for maintaining an exceptional safety record

Certificates

- Certified Cottrell Operator (CCO)

- Certified Maintenance Technician (CMT)

- OSHA 30Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cottrell Operator

- Highlight your technical expertise in Cottrell precipitator operations and maintenance.

- Showcase your experience in EPA regulations compliance and environmental protection.

- Quantify your accomplishments in terms of reduced emissions, improved efficiency, and cost savings.

- Emphasize your leadership and problem-solving skills.

- Include relevant certifications or training programs in your resume.

Essential Experience Highlights for a Strong Cottrell Operator Resume

- Optimized Cottrell precipitator operation, reducing emissions by 20%.

- Improved Cottrell efficiency by implementing a predictive maintenance program, extending equipment life by 15%.

- Successfully troubleshooted and resolved critical Cottrell malfunctions, minimizing downtime and ensuring continuous operation.

- Developed and implemented training programs to enhance team proficiency in Cottrell operations and maintenance.

- Led a project to upgrade the Cottrell control system, resulting in improved performance and reduced operating costs.

Frequently Asked Questions (FAQ’s) For Cottrell Operator

What is the primary function of a Cottrell Operator?

A Cottrell Operator is responsible for the operation, maintenance, and troubleshooting of Cottrell precipitators, which are devices used to remove particulate matter from industrial emissions.

What are the key skills required for a successful Cottrell Operator?

Key skills for a Cottrell Operator include a strong understanding of Cottrell precipitator technology, electrical and mechanical troubleshooting, preventive maintenance, and EPA regulations compliance.

What are the career prospects for a Cottrell Operator?

Cottrell Operators with experience and qualifications can advance to supervisory roles, environmental compliance specialists, or technical consultants.

What are the typical working conditions for a Cottrell Operator?

Cottrell Operators typically work in industrial environments, such as power plants or manufacturing facilities. They may be exposed to dust, noise, and other hazardous conditions.

What is the average salary for a Cottrell Operator?

The average salary for a Cottrell Operator can vary depending on experience, location, and industry. According to Indeed, the average salary for a Cottrell Operator in the United States is approximately $65,000 per year.

What are the safety measures that Cottrell Operators must follow?

Cottrell Operators must adhere to strict safety protocols, including wearing appropriate protective gear, following lockout/tagout procedures, and being aware of potential hazards such as electrical shock and exposure to hazardous chemicals.