Are you a seasoned Counter Molder seeking a new career path? Discover our professionally built Counter Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

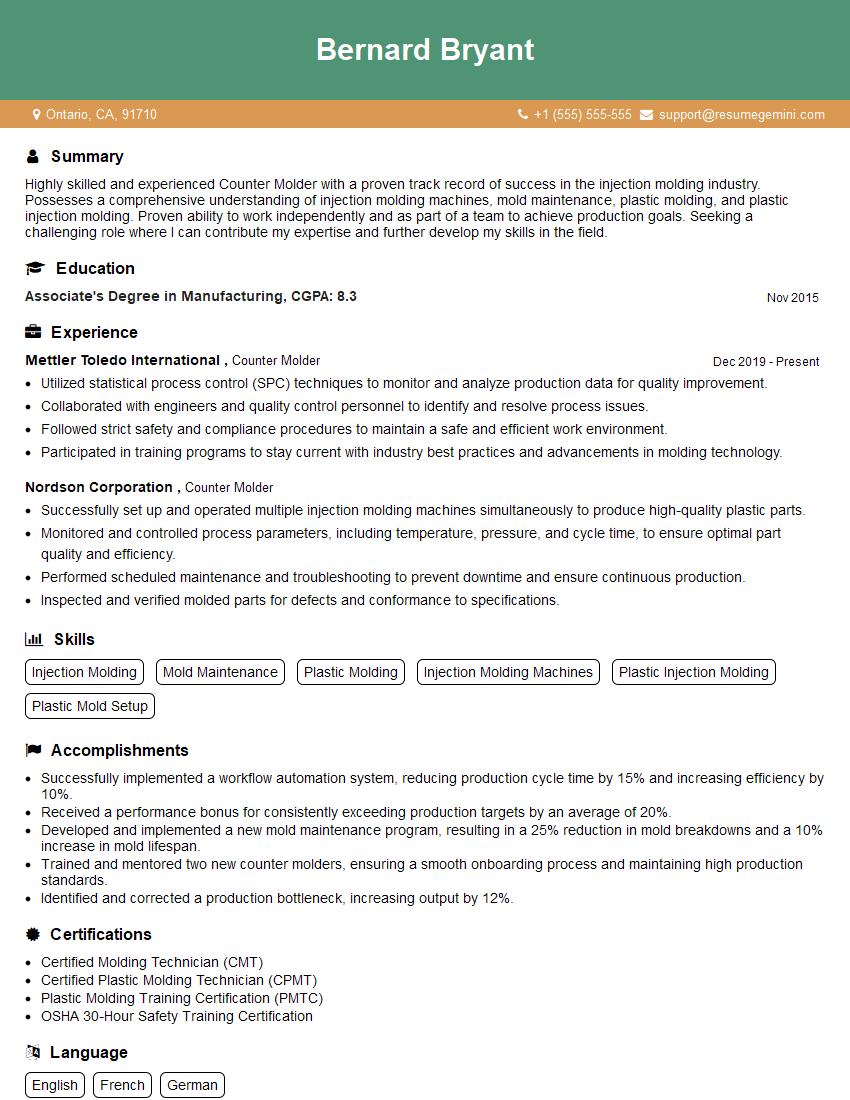

Bernard Bryant

Counter Molder

Summary

Highly skilled and experienced Counter Molder with a proven track record of success in the injection molding industry. Possesses a comprehensive understanding of injection molding machines, mold maintenance, plastic molding, and plastic injection molding. Proven ability to work independently and as part of a team to achieve production goals. Seeking a challenging role where I can contribute my expertise and further develop my skills in the field.

Education

Associate’s Degree in Manufacturing

November 2015

Skills

- Injection Molding

- Mold Maintenance

- Plastic Molding

- Injection Molding Machines

- Plastic Injection Molding

- Plastic Mold Setup

Work Experience

Counter Molder

- Utilized statistical process control (SPC) techniques to monitor and analyze production data for quality improvement.

- Collaborated with engineers and quality control personnel to identify and resolve process issues.

- Followed strict safety and compliance procedures to maintain a safe and efficient work environment.

- Participated in training programs to stay current with industry best practices and advancements in molding technology.

Counter Molder

- Successfully set up and operated multiple injection molding machines simultaneously to produce high-quality plastic parts.

- Monitored and controlled process parameters, including temperature, pressure, and cycle time, to ensure optimal part quality and efficiency.

- Performed scheduled maintenance and troubleshooting to prevent downtime and ensure continuous production.

- Inspected and verified molded parts for defects and conformance to specifications.

Accomplishments

- Successfully implemented a workflow automation system, reducing production cycle time by 15% and increasing efficiency by 10%.

- Received a performance bonus for consistently exceeding production targets by an average of 20%.

- Developed and implemented a new mold maintenance program, resulting in a 25% reduction in mold breakdowns and a 10% increase in mold lifespan.

- Trained and mentored two new counter molders, ensuring a smooth onboarding process and maintaining high production standards.

- Identified and corrected a production bottleneck, increasing output by 12%.

Certificates

- Certified Molding Technician (CMT)

- Certified Plastic Molding Technician (CPMT)

- Plastic Molding Training Certification (PMTC)

- OSHA 30-Hour Safety Training Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Counter Molder

- Highlight your experience and skills in injection molding, mold maintenance, and plastic molding.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Proofread your resume carefully for any errors.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Counter Molder Resume

- Set up, adjust, and operate injection molding machines to produce plastic parts according to specifications.

- Monitor and maintain injection molding machines, including cleaning, lubrication, and troubleshooting.

- Inspect finished parts for quality and dimensional accuracy, and make adjustments as needed.

- Troubleshoot and resolve problems with injection molding machines and molds.

- Maintain a clean and organized work area.

- Follow safety procedures and regulations.

Frequently Asked Questions (FAQ’s) For Counter Molder

What is the role of a Counter Molder?

A Counter Molder is responsible for setting up, operating, and maintaining injection molding machines to produce plastic parts. They also inspect finished parts for quality and dimensional accuracy, and troubleshoot and resolve problems with injection molding machines and molds.

What are the qualifications for becoming a Counter Molder?

Most Counter Molders have an Associate’s Degree in Manufacturing or a related field. They also have experience in injection molding, mold maintenance, and plastic molding.

What are the key skills for a Counter Molder?

Key skills for a Counter Molder include injection molding, mold maintenance, plastic molding, injection molding machines, plastic injection molding, and plastic mold setup.

What is the job outlook for Counter Molders?

The job outlook for Counter Molders is expected to be good over the next few years. The demand for plastic products is growing, and Counter Molders are needed to produce these products.

What is the average salary for a Counter Molder?

The average salary for a Counter Molder is around $20 per hour.

What are the benefits of being a Counter Molder?

Benefits of being a Counter Molder include job security, a good salary, and the opportunity to work with cutting-edge technology.